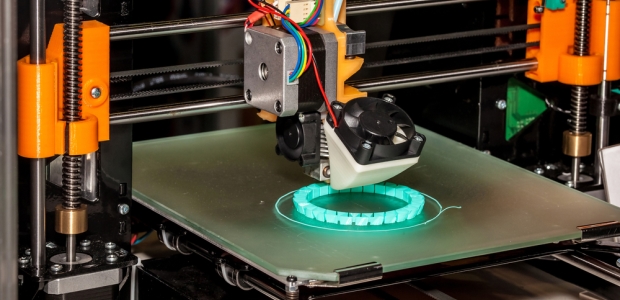

Study Calls 3D Printing's Safety Into Question

"The use of HEPA, as well as activated carbon filters does not solve the problem of air pollutants formed during 3D printing and there is the need for a new filtration system," the authors wrote. "Photocatalytic filters are one of possible solutions."

A study newly published in the Journal of Occupational and Environmental Hygiene (JOEH) confirms that commonly used and commercially available thermoplastic filaments (acrylonitrile-butadiene-styrene, polylactic acid, polyethylene terephthalate, and nylon) used in these printers emit volatile organic compounds (VOCs) during the printing process. JOEH is published jointly by the American Industrial Hygiene Association® and the American Conference of Governmental Industrial Hygienists (ACGIH®), which are also co-sponsors of the AIHce EXP conference next month in Seattle.

The conference program includes a session about 3D printing on Monday, June 5, starting at 10 a.m.

The study's authors are Szymon Wojtyła and Tomasz Baran of SajTom Light Future Ltd. in Czaniec, Poland -- Baran is also affiliated with the Department of Chemistry at the University of Milan, Italy -- and Piotr Klama of 3DKreator in Cracow, Poland. ACGIH notes that EPA has found excessive exposure to VOCs can lead to eye, nose, and throat irritation; headaches; loss of coordination; and nausea.

"The use of HEPA, as well as activated carbon filters does not solve the problem of air pollutants formed during 3D printing and there is the need for a new filtration system," the authors wrote. "Photocatalytic filters are one of possible solutions. Photocatalytic air treatment has the potential for degradation of organic and inorganic contaminants including volatile organic compounds from air." They recommend using good ventilation and also reported that the first fused deposition modeling (FDM) 3D printer (Accura Genius3D) equipped with a photocatalytic filtration system has been commercially available since September 2016.

The authors found that the four common filaments emit VOCs even at temperatures below the printing temperature.