Understanding the Modern Single Use Glove

Glove construction now takes into account long-term usability to reduce finger fatigue, chronic skin conditions, and more troublesome musculoskeletal disorders.

Today's single use gloves have come a long way since their first days in medical applications. From colors to construction, this often overlooked piece of PPE has had some pretty significant upgrades over the past few years. Originally designed to merely protect the wearer from exterior elements of their environment, single use gloves now take a more holistic hand health approach, focusing on both the interior of the glove as well as the exterior.

But even those that wear them may not fully understand all that goes into the design and manufacture of a single use glove, and many still think of these tools as a commodity product, with little differentiation between a good glove and a not-so-good one. Here, we dispel some of the common myths surrounding single use gloves to show how they have evolved to provide better performance, improved hand health, and increased ergonomics.

Misconception #1: Gloves today are the same as they were 10 years ago.

Although they may look the same, single use gloves manufactured in the last few years employ a number of different materials and formulations designed to withstand various environments, from oil and grease to caustic chemicals.

Glove quality is tied directly to the quality of the materials used in the glove's manufacturing and how those materials are brought together. A better constructed nitrile glove will have a higher-quality blend of polymers that minimize fillers or other materials that reduce effectiveness. A lower AQL rating, signifying superior water impermeability, can indicate improved quality overall, while the ability to achieve confirmed ratings for chemical and abrasion resistance can likewise be evidence that a glove has been engineered to higher standards.

In what seems to be a never-ending pursuit of cost cutting, many gloves can include additives designed to allow the glove to release from the manufacturing process quicker, to cure faster or to be easier to pack. Chemicals such as silicone, typically added to help keep the gloves from sticking together or clumping in the packaging, can be problematic in certain environments. In truth, there are no shortcuts to quality.

The best gloves are often those manufactured free of the chemicals and additives that may cause problems or that come from manufacturers who take particular care to completely cleanse products of unwanted contaminates before packaging.

There has also been a focus on obtaining a "near zero gradient," which is a fancy way to say the fingers, the palm, and the cuff should all be as close to the same thickness as possible. Why is this important? Because it reduces finger fatigue, as shown through studies conducted on modulus and thickness gradient as they relate to finger dexterity and tactility within a single use glove.

This results in greater productivity and efficiency and, long term, single use glove wearers are much less prone to musculoskeletal disorders. As a result of specifically engineered polymer formulations and intricate dipping motion control, these high-performance single use gloves demonstrate less tear, improved tactility, and a better-quality consistency for performance without the pain.

Misconception #2: 'Wet Work' comes with the territory.

Sticky, hot, slippery, messy. Anyone who wears single use gloves for extended periods of time will tell you, there’s just no way to get over that awful feeling of "wet work" . . . unless you have a moisture-wicking technology within the glove. Pulling the sweat away from the skin will not only keep hands drier and more comfortable, but also can reduce skin irritation and improve skin integrity.

Managed moisture equates to less friction within the glove, meaning dermal integrity is maintained and the skin can retain its natural protective barrier. When that natural barrier is compromised, skin is more susceptible to dermatitis, since bacteria, chemicals, and other irritants are more likely to pass through the outer skin layers and be absorbed quicker.

A moisture-wicking lining integrated into the single use glove itself provides a better interior environment that translates into less frequent and easier glove changes. Your glove becomes like a second skin instead of feeling like a sticky mess that inhibits your job performance.

Remarkably, even with the addition of this absorbent lining, the glove remains thin through a unique manufacturing process. Job performance is uncompromised, the glove provides added strength and durability, and the wearer is ensured a secure fit. Cotton liners are no longer needed because what once required these two separate layers is now combined into one single use glove that manages the occlusive environment better.

Misconception #3: There's no difference in skin conditioners used in a glove.

Safeguarding your skin is the first step in overall hand protection. If your hands are so irritated that it's uncomfortable to even put a glove on, you certainly won’t be happy keeping it on for several hours. It’s best to maintain the proper balance of pH and moisture on your skin to avoid more long-term hand health issues.

Single use gloves can be engineered with hand health agents, such as aloe vera, lanolin, glycerin or vitamin C, to minimize the effects of an occlusive environment and form a barrier between the glove and the skin. Additives can be combined together to create a protective environment or used in conjunction with other technologies to deliver a superior glove that provides hand health benefits as well as performance attributes.

Glycerin, a humectant, pulls moisture toward it. So in lower-humidity environments, it actually draws moisture from the deeper skin surfaces below and trap it at the skin's surface, essentially drying skin from the inside out. Although lanolin is a widely used additive, it’s an allergen to some, making it more of an irritant than a skin soothing remedy.

Vitamin C helps moisturize the skin and prevent wrinkles, but because it oxidizes very easily, it loses its effectiveness quickly. In addition, no studies have been done to determine which grade is best for a hand health environment.

One of the most beneficial additives is aloe vera, drawing from a 3,500-year history of effective skin care. It has anti-inflammatory properties, has been proven to accelerate the skin’s healing process, and also improves skin hydration.

pH balancing is one of the more recent technological advances in single use glove additives. The natural pH for hands is around 5.5, but the occlusive environment inside a glove results in elevated pH values closer to the neutral 7.0-7.5 range.

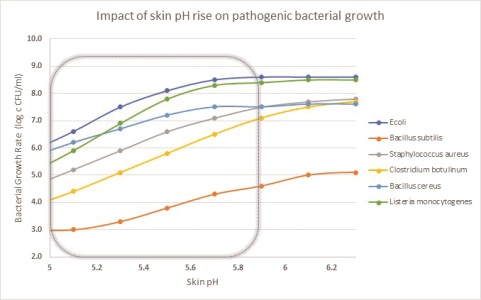

Studies have shown that the skin on your hands is much more capable of utilizing the enzymes it needs to maintain hydration and barrier integrity at lower pH levels, which naturally occur when not wearing gloves. Keeping the pH level within a glove low is an important hand health criterion. And a lower pH level inside a managed glove interior can dramatically decrease the growth of harmful or dangerous microbes, as the chart below shows.

These factors are a strong indication of why nature provides a lower, slightly acidic pH level on bare hands than what normally is experienced in the artificial environment of a sealed, air- and water-tight glove.

Misconception #4: Cheaper gloves save you money.

They're disposable, so the cheapest ones will work fine, right? Wrong! Take into account these all too common scenarios:

- Wasted inventory: How many times have you heard a co-worker sigh in frustration as the gloves he is donning rip at the cuff or the finger even before he walks away from the box. Those gloves never had a chance and go right into the trash bin.

- Wasted productivity: Now that the glove has failed, your co-worker gets another new pair from the box and tries to don them again . . . without tearing them this time. And if the glove ripped that easily when being put on, how long do you think it will last in an actual work environment where you're handling grease and chemicals or working around equipment with sharp corners or edges? Even more frustration.

- Wasted downtime: So your co-worker finally has a pair of gloves she was able to wear for an hour or two before the "wet work" became unbearable or the material's integrity started to break down. Time for another change, another rapid exposure of the skin going from hot and humid to cold and arid, and increased potential for skin irritation that could lead to contact dermatitis. Now you are faced with workers who can’t perform their job responsibilities because they can't wear the required PPE.

Still think cheaper is better?

All Gloves Are Not Created Equal

If you haven’t examined the current lineup of single use gloves, you might want to take a look. The glove of yesterday is a far cry from the glove of today.

Going beyond barrier protection, today's single use gloves offer a higher level of hand protection by managing not only the external factors that hands are exposed to, but the internal environment, as well. Additionally, glove construction now takes into account long-term usability to reduce finger fatigue, chronic skin conditions, and more troublesome musculoskeletal disorders.

This article originally appeared in the April 2017 issue of Occupational Health & Safety.