Page 5 of 3

Selecting Appropriate Respirators—A Complicated Matter

Respirators are among the most important pieces of personal protective equipment (PPE) and choosing the correct one can be a complicated matter. Properly selected, fitted, used, and maintained respirators protect workers from airborne hazards, but they do not eliminate the hazards. If a respirator is inappropriate for a particular task, the wearer risks exposure to the hazards. Choosing the right respirator is the key.

Respiratory Hazards

During a normal day, the air we breathe is mostly nitrogen and oxygen. It does, however, contain trace amounts of harmful respiratory hazards. Fortunately, our lungs have protective mechanisms that keep those trace hazards from harming us. With repeated overexposure to harmful respiratory hazards, as may be the case in the workplace, our lung’s protective mechanisms break down, and we are at risk.

How hazardous a substance is depends upon its toxicity, chemical state, physical form, concentration, and the length of exposure. Examples of potential respiratory hazards include particulates (airborne dusts, fibers, fumes, mists, smoke, and biological contaminants—bacteria, viruses, and fungi), gases, vapors, and oxygen-deficient atmospheres. Gases expand freely to fill any and all available space. Vapors are the gaseous states of substances that are either liquids or solids at room temperature.

Normal air has an oxygen concentration of 20.8 percent. When this concentration drops below 19.5 percent, the air is oxygen deficient and considered immediately dangerous to life and health (IDLH).

OSHA’s Three Lines of Defense

Engineering controls, administrative controls, and personal protective equipment (PPE) are methods that employers implement to eliminate or reduce workplace respiratory hazards. Following OSHA's Three Lines of Defense philosophy dictates that engineering and administrative controls must always be considered first: "In the control of those occupational diseases caused by breathing air contaminated with harmful dusts, fogs, fumes, mists, gases, smokes, sprays, or vapors, the primary objective shall be to prevent atmospheric contamination. This shall be accomplished as far as feasible by accepted engineering control measures," 29 Code of Federal Regulations (CFR) 1910.134(a)(1).

Engineering controls include general and local ventilation, enclosure or isolation of the process or equipment, and substitution of less hazardous substances when possible. Administrative controls limit employees' exposures by scheduling reduced work times in contaminant areas or by implementing other such work rules. "When effective engineering controls are not feasible, or while they are being instituted, appropriate respirators shall be used pursuant to this section," 29 CFR 1910.134(a)(1).

Appropriate respiratory protection is a vital last line of defense.

What? How Much?

To protect yourself and your employees from respiratory hazards, you must first identify the hazards, then quantify the exposure, and finally use this information to select the proper respirator. When selecting respirators, you also must take into account the wearer’s medical condition and comfort and the configuration of the job site.

To identify the hazards, consider the sources—production processes, raw materials, intermediate materials, finished materials, and byproducts. Review the applicable safety data sheets. Review injury and illness reports and talk to the employees. Have they reported signs or symptoms of respiratory distress?

After identifying the respiratory hazards, then you must quantify how much employee exposure there is. Several approaches are permitted for estimating exposure to respirator hazards, but personal exposure monitoring is generally preferred; it is the most reliable. Another option is to sample the air at specific locations to estimate exposures that may affect groups of employees. You also can use objective information, such as data on the physical and chemical properties of the hazard combined with information on room dimensions, air exchange rates, and contaminant release rates, to estimate the maximum exposure.

Another approach is to use representative exposure data from industry studies, trade associations, or product manufacturers to estimate exposure. If this approach is chosen, you must be able to show that the data are based on conditions similar to those that exist within your work environment.

Assigned Protection Factors and Maximum Use Concentration

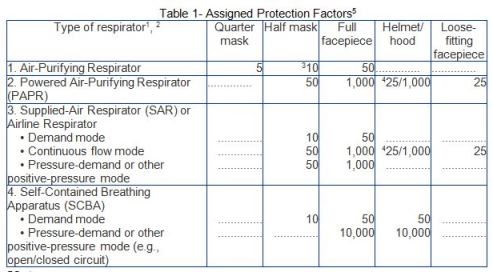

Assigned protection factors (APFs) are defined as the level of respiratory protection that a respirator or class of respirators is expected to provide to employees when the employer implements a continuing, effective respiratory protection program. "Employers must use the assigned protection factors listed in Table 1 to select a respirator that meets or exceeds the required level of employee protection" 1910.134(d)(3)(i)(A).

Notes:

1. Employers may select respirators assigned for use in higher workplace concentrations of a hazardous substance for use at lower concentrations of that substance, or when required respirator use is independent of concentration.

2. The assigned protection factors in Table 1 are only effective when the employer implements a continuing, effective respirator program as required by this section (29 CFR 1910.134), including training, fit testing, maintenance, and use requirements.

3. This APF category includes filtering facepieces, and half masks with elastomeric facepieces.

4. The employer must have evidence provided by the respirator manufacturer that testing of these respirators demonstrates performance at a level of protection of 1,000 or greater to receive an APF of 1,000. This level of performance can best be demonstrated by performing a WPF or SWPF study or equivalent testing. Absent such testing, all other PAPRs and SARs with helmets/hoods are to be treated as loose-fitting facepiece respirators and receive an APF of 25.

5. These APFs do not apply to respirators used solely for escape. For escape respirators used in association with specific substances covered by 29 CFR 1910 subpart Z, employers must refer to the appropriate substance-specific standards in that subpart. Escape respirators for other IDLH atmospheres are specified by 29 CFR 1910.134 (d)(2)(ii).

Maximum use concentration (MUC) is the maximum atmospheric concentration of a hazardous substance from which an employee can be expected to be protected when wearing a respirator. The MUC for respirators is calculated by multiplying the APF for the respirator by the established permissible exposure limit (PEL). Whenever the exposures approach the MUC, the employer should select the next higher class of respirators for the employees. Employers must not apply MUCs to conditions that are immediately dangerous to life or health (IDLH).

Employers must use the APFs and MUCs to select the appropriate type of respirators. Selection is based on the exposure level found in the workplace and the maximum concentration of the contaminant for which a particular type of respirator can be used.

Example APF and MUC calculations are outlined below:

If the workplace concentration of organic vapor contaminant "A" is 70 parts per million (ppm) and the permissible exposure limit (PEL) for the organic vapor contaminant "A" is 10 ppm, the protection factor needed is 7 (70÷10). The minimum APF one can choose from Table 1 and meet the requirement for the protection factor needed is 10. The MUC for a respirator with an APF of 10 in this example is 100 ppm (10x10). Because 70 ppm is less than the MUC, a half mask with the appropriate organic vapor cartridges is allowed.

The Advisor Genius

An expert technical advisor is available online to assist you in choosing the proper respirator: https://www.osha.gov/SLTC/etools/respiratory/respirator_selection_advisorgenius.html

The Advisor Genius is based on the National Institute for Occupational Safety and Health (NIOSH) Respirator Decision Logic and the Respirator Standard (29 CFR 1910.134).

Voluntary Respirator Use

OSHA is very clear on voluntary use of respirators. Voluntary use means:

- An exposure assessment has been conducted;

- The permissible exposure limit (PEL) is not exceeded;

- No OSHA regulation requires that respirators be provided by the employer (For example, 29 CFR 1910.1025 requires employers to provide respirators upon request to employees exposed to lead at any concentration.);

- The employer does not believe it is necessary to reduce exposures below their current levels (i.e., there is no perceived hazard);

- The employer does not require, recommend, encourage, or suggest that respirators be used;

- Workers ask to wear respirators; and

- Respirators will not be used for emergency response or escape.

If one or more of these conditions are not met, respirator use is not voluntary.

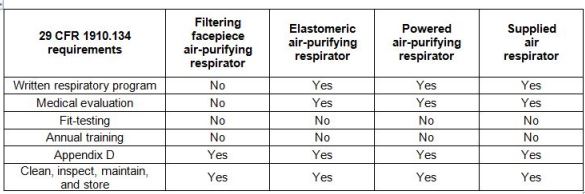

Employers who allow voluntary respirator use must make sure the worker is medically able to use the respirator and that the respirator itself does not create a hazard. The employer must implement certain elements of a respiratory protection program based on the type of voluntary respirator used. Requirements based on the type of voluntary respirator used are summarized below:

Conclusion

When respiratory hazards cannot be eliminated and employers are considering using respiratory protection, choosing the right respirator is the key. Critical steps for selecting proper respirators include:

1. Identifying the respiratory hazards

2. Evaluating the exposure levels to determine the airborne concentration of the hazards

3. Determining the atmospheric oxygen concentration

4. Selecting the respirator based on the hazards' airborne concentration, chemical form, physical form, and the available oxygen

5. Using only NIOSH-certified respirators

This article originally appeared in the November 2016 issue of Occupational Health & Safety.

About the Author

Sally J. Smart, CSP, is a technical safety specialist at Grainger, a leader in safety services and solutions, offering technical support and training to help customers comply with workplace safety regulations and safeguard facilities. For more information on creating a safer working environment, visit http://safety.grainger.com.