All In for Chemical Safety!

Workplace labels must include the product identifier and general information regarding all of the hazards of the chemical(s).

- By Robert A. Ernst

- May 01, 2016

On March 26, 2012, OSHA published the revised Hazard Communication Standard (HCS), "harmonizing" it with portions of the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). In order to minimize the disruptions to employers, OSHA phased in the requirements of the revised standard over four years.

The previous, staggered compliance dates for HCS implementation addressed employee training; container labeling and safety data sheets (SDSs); and employer compliance with written plan and labeling requirements.

The final implementation date is June 1, 2016. By that date, all employers must:

- Update alternative workplace labeling as necessary,

- Update their hazard communication (HazCom) program as necessary, and

- Provide additional employee training for newly identified physical or health hazards.

But just what does that mean to you? How do you identify new hazards that you haven't had to label for or train on previously?

Identify New Hazards

Because of the way OSHA now identifies, or "classifies," chemical hazards, your chemicals may have "new" hazards. To identify these new chemical hazards, OSHA expects the employer, or whoever is responsible for the workplace HazCom program, to review the container labels and the SDSs for the hazard classifications.

Where new hazards are identified on the label or the SDS, because of the adoption of GHS classifications, those new hazards must be reflected in the HazCom program, as needed. If you identify new chemical hazards, you must make sure that workplace labeling reflects those new hazards and that employees are trained on those hazards. For instance, a chemical might now carry a classification as an eye irritant or as corrosive to metal. These new hazards would have to be evaluated and be reflected in the written program and employee training. Or the chemical may not have been considered hazardous before, but it is considered hazardous under the new classification system. That chemical would have to be added to the workplace chemical inventory.

Labeling

New shipments of hazardous chemicals will arrive at your establishment properly labeled under the HCS. Incoming labels on shipped containers may not be removed or defaced unless the container is immediately marked with the required information, such as a workplace label.

Workplace labels—also called secondary, internal, in-house, or in-plant labels—can duplicate the supplier’s label elements or can be an alternative labeling system. Workplace labels must include the product identifier and general information regarding all of the hazards of the chemical(s).

The NFPA and HMIS rating systems do not correlate with the HCS classifications. The NFPA and HMIS rating of 1 indicates a "low" hazard, while the HCS classification of 1 represents the greatest hazard. However, the HMIS or NFPA system may be used as part of an employer's workplace labeling system if used in accordance with the NFPA and HMIS guidelines and as long as it does not cast doubt or contradict the validity of the label information.

In some cases, all hazards are not addressed by a particular rating system, such as chronic health hazards. Therefore, hazards not addressed must be communicated by words, pictures, symbols, or a combination thereof in addition to the NFPA or HMIS rating system.

You do not have to update labels on containers already in your facility, even if the containers are labeled under HCS 1994, unless you will be shipping them out of your facility. However, if you become aware of newly identified hazards that are not disclosed on the label, you must ensure that the workers are made aware of the hazards, such as with updated labels.

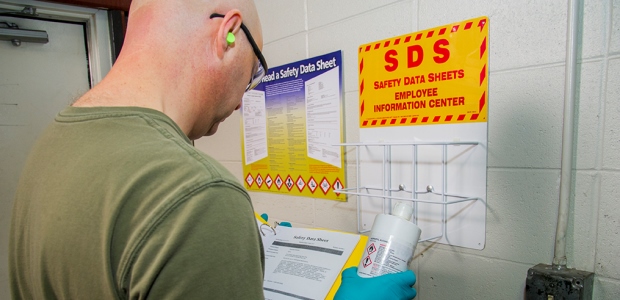

Safety Data Sheets (SDSs)

Employers must maintain the current version of the SDS; if a new SDS is received with a shipment, they must maintain it and make it available.

You should not receive any new shipments of hazardous chemicals that do not have a revised SDS. If you do not receive an SDS with or prior to any new shipments of a chemical, you can request one from your supplier.

Employers may rely on the information received from their suppliers unless they know the information is incorrect. If you receive an SDS that is obviously inadequate—with, for example, blank spaces—you must request a compliant one. If you cannot get a compliant SDS after requesting one, contact your local OSHA area office for assistance. Employers assume no responsibility for the content and accuracy of the SDS provided to them by the manufacturer, importer, or distributor, unless the employer changes the SDS.

The SDS must be provided and maintained in English. However, the SDS may be translated into other languages that workers speak to aid in comprehension and training. There is no requirement to translate SDSs; however, it is recommended that the employer ensure information from the SDS is available to the employees in a manner they would understand easily in case of an emergency.

OSHA does not require employers to contact manufacturers, importers, or distributors to obtain new SDSs of products for which they currently have MSDSs. You must maintain the most recent data sheet you have received for a product. OSHA does not consider an employer to be in violation if that employer is maintaining an MSDS for a product unless the supplier has provided a newer version and the employer is not maintaining it.

If the manufacturer has gone out of business, the employer's responsibility is to maintain the SDS (or MSDS) for that product and not to create a new SDS.

Employers may contact manufacturers, importers, or distributors of products they have previously ordered from to request new SDSs, and if they do so, the manufacturer or importer must provide the SDS.

Training

Employers are required to inform employees of the basic requirements of the standard, such as specific chemical hazards in the employee's work area, the location of the written HazCom program and SDSs, and how to read container labels and SDSs.

Hazardous chemical training must include:

- How to detect the presence or release of hazardous chemicals;

- The physical and health hazards of those chemicals; and

- Precautions employees can take to protect themselves against hazards, such as safe work practices, personal protective equipment, and emergency procedures.

OSHA requires training to be comprehensible. If the employees receive job instructions in a language other than English, then the training and information to be conveyed under the HCS also will need to be conducted in that language. If an employee's vocabulary is limited, the training must account for that limitation. By the same token, if employees are illiterate, telling them to read training materials will not satisfy the employer's training obligation.

In multi-employer work sites, each employer is responsible for providing updated training when its own employees are exposed to new hazards, even if these hazards are created by other employers. The host employer (the company using temporary workers) holds the primary responsibility for training because it uses or produces chemicals, creates and controls the hazards, and is therefore best suited to inform employees of the chemical hazards specific to the workplace environment through site-specific training. This duty includes identifying and communicating work site-specific hazards and providing appropriate protective equipment to temporary workers. The HCS training provided to temp workers should be identical or equivalent to that given to the host’s own employees.

The Written Plan

Employers are required to prepare and implement a written hazard communication program, including employers on a multi-employer work site who may expose their employees or the employees of other employers to hazardous chemicals. The written program is intended to ensure that the employer is in compliance with all of the required elements of the standard. The written plan must include a list of the hazardous chemicals known to be present, using a product identifier that aligns with the SDS and the label.

An employer on a multi-employer work site must include in its program the methods it will use to provide other employers with on-site access to SDSs. This covers each hazardous chemical to which the other employers’ employees may be exposed.

Therefore, one employer does not have to physically give the other employer the SDSs, but rather must inform others of the location where the SDSs will be maintained (e.g., in the general contractor's trailer). The HCS allows employers to decide on the method of information exchange.

Staying in Compliance

Now is the perfect time for employers to review their HazCom program. OSHA believes that most employers will not have to make extensive revisions to their written programs, including the chemical inventory, because of the June 1 date.

But because that date is coming up, employers can use it as an opportunity to examine their HazCom program for compliance. Ensuring that your program addresses OSHA's requirements, especially the means of communicating information to employees in the workplace, will help you stay in compliance.

This article originally appeared in the May 2016 issue of Occupational Health & Safety.