NIST to Fund Manufacturing Innovation Institutes

Up to two will be funded with as much as $70 million each. This time, NIST hasn't defined an area of focus; the agency says it is open to receiving proposals in any topic of interest to industry, particularly those relevant to manufacturing robotics and biopharmaceutical manufacturing.

The U.S. Commerce Department's National Institute of Standards and Technology (NIST) announced Dec. 22 that it has issued a notice of intent to fund up to two institutes as part of the National Network for Manufacturing Innovation. They will be funded with up to $70 million each for five to seven years; Commerce Department funding must be matched by private and other non-federal sources, and the institutes are expected to become self-sustainable within the time period of the award.

"Today marks a major milestone for the future of American innovation," said U.S. Secretary of Commerce Penny Pritzker. "The collaborative, cutting-edge technologies being designed, developed, and commercialized at our NNMI institutes are essential to America's long-term economic growth, competitiveness, and job creation. Our new institutes will build on the success of the existing seven and, for the first time, the topic areas have not been chosen in advance but will depend on industry interests and input. Together, our growing network of institutes will ensure America remains on the leading edge of the 21st century economy."

"Each institute serves as a regional hub of manufacturing excellence, providing the innovation infrastructure to reinforce the competitiveness of the U.S. manufacturing sector as a whole," said NIST Director Willie E. May. "NIST is pleased to support this national effort to build critical capacity in important technology areas, in support of U.S. manufacturing."

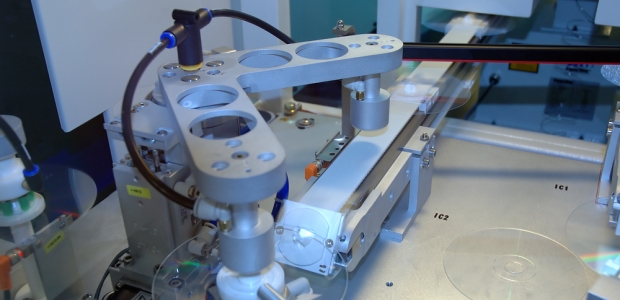

In its announcement, NIST stated it is open to receiving proposals in any topic of interest to industry, particularly those relevant to manufacturing robotics and biopharmaceutical manufacturing -- two areas identified by the President's Council of Advisors on Science and Technology Advanced Manufacturing Partnership as technology areas critical to supporting national needs. As NIST described them, a "collaborative manufacturing robotics institute would focus on developing advanced robotic systems that can safely operate in collaboration with humans or other robots, be tasked and re-tasked easily, and be integrated into the rest of an enterprise seamlessly and quickly. A biopharmaceutical manufacturing institute would center on 'biologic' therapies that are manufactured using living cells instead of conventional chemistry. The institute would aim to stimulate innovation in manufacturing that will enable new, more cost effective treatment of disease and solidify the domestic competitiveness of the U.S. biopharma industry."