Page 3 of 3

Clear the Fog to Decrease Eye Injuries

Workplace eye injuries occur—quite literally—in a blink. In fact, in the time it takes to read this article, there will be about 15 eye injuries requiring medical treatment, more than one a minute. Each day there are approximately 2,000 workplace eye injuries requiring medical attention, about a quarter of all injuries to the head, according to the Bureau of Labor Statistics (BLS).

The impact of those injuries is enormous. To begin, the human toll is devastating; 10-20 percent of workplace eye injuries cause temporary or permanent vision loss. More than a million Americans have lost a portion or all of their sight from an eye injury. The cost to industry is staggering, as well. According to a BLS report, the average lost time for a treated eye injury is two work days. The bottom line? The impact of eye injuries was some $4 billion in lost wages and productivity in a recent year.

Why haven't safety glasses reduced eye injuries more?

As much as 90 percent of all eye injuries could be prevented by the use of proper protective eyewear, according to Prevent Blindness America. So why is the incidence of injury still so high? There are still industries and workplaces that have inadequate or no safety eyewear policy. A problem of equal concern is worker non-compliance with eyewear policy.

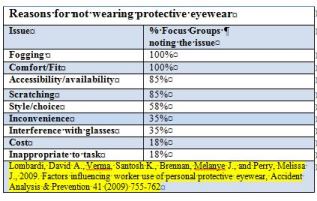

A number of factors can influence non-compliance, and fogged eyewear is a significant one. In a study published in Accident Analysis & Prevention, researchers found that fogging was the number one vision-related barrier to wearing safety eyewear in the workplace. More than half the respondents suggested an anti-fog solution could help increase compliance. Research by Nanofilm among safety professionals corroborates those findings: 28 percent of respondents reported fogged safety eyewear had contributed to injury in their workplace. A full 66 percent said fogging was a deterrent to wearing safety eyewear.

Two specific injury risks come to mind. First, when safety eyewear fogs up under hot or steamy conditions, workers may simply take them off, exposing themselves to a variety of hazards. The second risk of fogged eyewear is impaired vision that can leave the outdoor worker open to injury while handling everyday tasks—a fact well understood by safety professionals who deal with high-heat indoor environments, such as utilities, metal fabrication, and paper mills.

There is often a loss of productivity for workers struggling with fogged eyewear. A person who removes, wipes, and re-dons safety eyewear again and again during a shift can’t be working up to potential.

Take Control to Prevent Eye Injuries

Fogged eyewear is a year-round hazard for many, but the danger can increase significantly for outdoor workers in the summer. Educational materials on heat stress from both the Centers for Disease Control and the Occupational Safety and Health Administration advise that "Exposure to heat can also increase the risk of injuries because of . . . fogged-up safety glasses."

Fogged eyewear is a year-round hazard for many, but the danger can increase significantly for outdoor workers in the summer. Educational materials on heat stress from both the Centers for Disease Control and the Occupational Safety and Health Administration advise that "Exposure to heat can also increase the risk of injuries because of . . . fogged-up safety glasses."

There are three interrelated reasons for the summertime fog hazard increase: heat, humidity, and human exertion. Fortunately, all can be mitigated.

Let's begin with a little science reference. We are all familiar with the way water droplets form on the outside of a cold glass of iced tea on a hot summer day. The glass, kept cold by the icy tea, is much cooler than the surrounding air, causing moisture to condense out of the air and onto the glass. With safety eyewear, the effect is similar. The safety glasses are cooler than the ambient air, the higher humidity level puts more moisture into the air. The result? A greater risk of fog condensing on the lenses. The fact that the eyewear is close to the worker's face further increases the fog risk. The air trapped between the glasses and the wearer’s face is hotter and more humid because the worker’s skin is hotter and perspiring, increasing the likelihood of fog. Workers who never experience a problem during the rest of the year may see one develop in summer.

Today's wraparound eyewear designs increase the fog problem even more. The tighter fit hugs the face, reducing air flow and preventing the dissipation of heat and moisture. For workers wearing goggles or eyewear under a faceshield, the airflow problem becomes even more pronounced. This may include those wearing prescription glasses under safety eyewear, as well as welders, who are required by regulation to wear both a faceshield and impact-resistant safety eyewear.

As OSHA notes, fogged safety eyewear is a factor in hot-weather injury risk, and, as a result, the topic needs to be incorporated into your summer heat stress safety planning:

- Introduce fog danger as part of heat stress training. Make employees aware of the seasonal problem and how to address it: 1. Explain the potential for fogging problems. 2. Review the organization's safety eyewear policy and the injury risks of removing safety eyewear or working with fogged-up lenses. 3. Inform workers of solutions available from the company.

- Provide ways to prevent fogging. Make anti-fog treatments readily available. Keep a visible supply where workers don and doff their gear, as well as in break and rest areas. Supervisors may want to carry anti-fog with them to give to workers who are experiencing a problem. You can also consider providing safety eyewear with anti-fog lenses, as well as frame styles that improve air flow.

- Remember to address other barriers to safety eyewear compliance that might be aggravated by heat and humidity. 1. No-sweat comfort. When nosepieces or temples get sweaty and slippery, they can slip off or chafe. A worker may solve the problem with a different eyewear design. 2. Provide a strap. If glasses are removed during a break, they are less likely to be left on a bench or in the truck.

- Emphasize that the policy applies to all personnel. Individuals who are passing through a danger zone must follow the same protocols as workers who spend the full work day in the area. Be especially cognizant to have supervisory staff model safe behavior.

- Be vigilant about compliance. If you see workers without eyewear, address it immediately and look into root causes.

Six Tips to Promote Year-Round Vision Safety, Indoors and Out

For much of the country, temperatures will begin to cool in the coming weeks. While hot weather fogged eyewear problems will begin to fade, vision protection is a 24/7/365 safety issue, both outdoors and indoors. Here are six tips for helping to improve compliance with safety eyewear mandates and protect workers' vision.

1. Address fogging issues, especially in high-heat indoor environments, such as metalworking, utilities, and pulp and paper manufacturing. OSHA guidelines, according to safety training professionals, indicate that fogging should be considered as part of an eyewear safety policy and program. Of course, the first step is a written hazard assessment (OSHA 1910.132(d)(2)) of the workplace. If hazard conditions indicate, personal protective equipment for the eyes should be provided. In addition, OSHA directs that the safety equipment be in "sanitary and reliable condition" (1910.132(a)). In certain workplaces, "reliable condition" may include a method for preventing fogging of safety glasses, safety goggles and faceshields. Furthermore, OSHA requires training for employees on required safety equipment (1910.132(f)(1)), which may need to include a discussion of eyewear fogging hazards.

2. Is it the right eyewear for the job? More than 90 percent of eye injuries that occurred while workers were wearing eye protection were the result of inappropriate protective eyewear: Foreign matter was able to enter around the periphery of the eyewear. Perhaps side shields, faceshields, or closed goggles should have been considered.

3. Keep PPE easily available: 80 percent of workers suggested accessibility as a factor in compliance. Is the supply room open regularly? Are safety glasses available by all facility doors? Would straps, lanyards, or cases help workers keep safety glasses close at hand?

4. Quality equipment is a smart safety investment: 85 percent of focus groups named scratching as a barrier to compliance.

5. Comfort—and a little style—aids compliance. A selection of different earpieces, nosepieces, and frame widths can help workers find a satisfying fit. And new styles that mimic fashion sunglasses make safety glasses a fashion statement.

6. Training and reminders work. OSHA mandates safety training, and safety professionals know its value. A once-a-year session isn't enough. Be sure to use posters and company newsletters and flyers as regular refreshers and reminders. Training resources are available through NIOSH, Prevent Blindness America, The Vision Council, and other organizations. And don't forget train-as-you-go efforts, such as thanking workers who've remembered their eyewear and correcting infractions on the spot.

This article originally appeared in the August 2015 issue of Occupational Health & Safety.

About the Author

Rex Talbott is Director-Optical for Nanofilm, which has been a leader in the eyewear industry for 30 years. The company manufactures eyewear care products, including Defog It anti-fog, that are used in safety and professional optical applications worldwide.