Heads Up!

Just as important as actually wearing a hard hat when needed is making sure the hard hat fits properly. Hard hats must fit securely to provide maximum protection.

- By Sally J. Smart

- Jul 01, 2015

The hard hat is a piece of personal protective equipment (PPE) designed to protect us when all other methods of protection cannot. Its use is often required since all hazards simply cannot be eliminated. Hard hats protect our heads when we are at risk from bumping our heads; from falling tools or materials when there are workers, machines, conveyor belts, etc. above us; from objects being carried or swung nearby; or from electrical shock and burns. These hazards exist in most workplaces in many different forms.

Hard hats are commonly worn by carpenters, construction workers, electricians, freight handlers, lineman, mechanics, plumbers, pipe fitters, timber cutting and logging operators, warehouse laborers, and welders.

Occupational Safety and Health Administration Guidance

The Occupational Safety and Health Administration (OSHA) guidelines for head protection are referenced in 29 CFR 1910.135 (General Industry) and 1926.100 (Construction).

29 CFR 1910.135(a)(1) states, "Each affected employee shall wear protective helmets when working in areas where there is a potential for injury to the head from falling objects." The standard also covers conditions where electrical hazards are present. 1910.135(a)(2) states, "Protective helmets designed to reduce electrical shock hazard shall be worn by each such affected employee when near exposed electrical conductors which could contact the head."

Construction

Depending on the intended use and the manufacturer, hard hat shells may be made of a thermoplastic resin such as polyethylene or polycarbonate, fiberglass, resin-impregnated textiles, or aluminum. Because it is strong, lightweight, easy to mold, and nonconductive to electricity, high-density polyethylene is used most often.

The suspension system consists of strips of woven nylon webbing and bands of molded high-density polyethylene, nylon, or vinyl. Suspensions are available with either four, six, or eight attachment points. Typically, hard hats with more suspension points spread out the potential force of a localized blow to the head by distributing the force over a broader area.

All hard hats are designed to provide protection from impact and penetration hazards. Some also provide protection from electric shock and burns.

Performance Criteria

The performance criteria for head protection are provided in the American National Standards Institute (ANSI)/International Safety Equipment Association (ISEA) Z89.1 American National Standard for Industrial Head Protection. This standard does not cover bump caps, firefighting helmets, or head protection devices used in recreational activities. ANSI/ISEA Z89.1 is incorporated by reference in 29 CFR 1910.135.

On Sept. 9, 2009, OSHA issued an update to its PPE standards. The final rule went into effect in October that year and revised the PPE sections of OSHA’s general industry, shipyard employment, longshoring, and marine terminals standards regarding requirements for eye and face protective devices, head protection, and foot protection. The revision updated the references in these regulations to recognize the more recent editions of the applicable national consensus standards.

ANSI/ISEA Z89.1-1997

Beginning with the ANSI Z89.1-1997 standard, Type I designates hard hats designed to reduce the force of impact resulting from a blow only to the top of the head, while Type II designates hard hats designed to reduce the force of impact resulting from a blow to the top or sides of the head. This revision also re-designated the electrical-protective classifications for hard hats as follows:

- Class G (general): Designed to reduce the danger of contact with low-voltage conductors and are proof tested at 2,200 volts

- Class E (electrical): Designed to reduce the danger of contact with conductors at higher voltage levels and are proof tested at 20,000 volts

- Class C (conductive): Provide no protection against contact with electrical hazards

ANSI/ISEA Z89.1-2003

The most significant changes from the 1997 version were made to harmonize with other national standards that test and evaluate equipment performance. In addition, many physical hard hat requirements that did not provide added user value, or that limited design or performance, were removed.

ANSI/ISEA Z89.1-2009

ANSI published a revision in January 2009. The significant changes from the 2003 version included three non-mandatory tests:

- Reverse donning: Hard hats marked with a reverse donning arrow can be worn frontward or backward in accordance with the manufacturer's wearing instructions.

- Lower temperature: Hard hats marked with an "LT" indicate the hard hat meets all testing requirements of the standard when preconditioned at a temperature of -30° C (-22° F).

- High visibility: Hard hats marked with an "HV" indicate the hard hat meets all testing requirements of the standard for high-visibility colors. This includes tests for chromaticity and luminescence.

ANSI/ISEA Z89.1-2014

ANSI/ISEA Z89.1-2014 was issued on May 15, 2014 and contains three main changes from the previous revision:

- Under the section of Accessories and Replacement Components, there is further clarification that accessory or component manufacturers are required to prove that their components do not cause the helmets to fail.

- Some additional language was added under the Instructions and Markings section to help clarify that "useful service life" for helmets is not required by the standard. It is up to helmet manufacturers whether they want to include specific service life in terms of years. Manufacturers can elect to specify the number of years for their helmet’s service life or elect to identify certain conditions that may affect a helmet's protective capability over time.

- The Higher Temperature section has been updated to incorporate an optional preconditioning at a higher temperature of 140º F +/- 3.6º F (60º C +/- 2º C). Previously hot temperature preconditioning was conducted at 120º F +/- 3.6º F (48.8º C +/- 2º C). Helmets that meet the performance criteria after being preconditioned to these higher temperatures (140º F) are designated with an HT marking.

Markings

Hard hats conforming to the requirements of ANSI Z89.1-2014 must be appropriately marked to verify compliance. The following information must be marked inside the hard hat:

- The manufacturer's name or identifying mark

- Date of manufacture

- The legend "ANSI Z89.1-2014"

- The type and class designation

- The approximate head size range

If optional performance features are applicable, the appropriate marking(s) must be applied in the sequence as shown below:

- Reverse Donning

- LT - Lower Temperature

- HV - High Visibility

- HT - Higher Temperature

Sizing

Just as important as actually wearing a hard hat when needed is making sure the hard hat fits properly. Hard hats should not be too big or too small. They must fit securely to provide maximum protection.

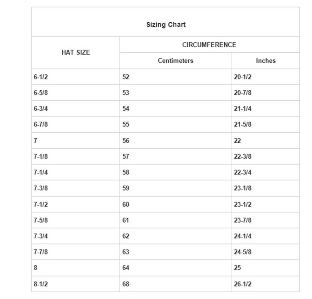

Hard hat sizes can seem a bit mysterious. To measure for your hat size, place a soft cloth tape measure around the widest part of your head (this is usually just above the eyebrows). Pull the tape measure snug, but not tight. Covert the measurement to your hat size using the chart shown below:

Inspection and Care

Before and after each use, hard hats should be inspected for wear and damage. Inspect the shell for breakage, cracks, discoloration, chalky dull appearance, or any other unusual condition. If any of these conditions exist, replace the hard hat. Always replace your hard hat if it has withstood an impact or penetration. Check the suspension for loss of flexibility, cracks, breaks, frayed straps, or damaged stitching. If any of these conditions are noticed, replace the suspension. Most hard hat manufacturers offer replacement suspensions as a standard replacement part.

Hard hats must be cleaned regularly in order to be adequately inspected. When not in use, they should be stored in a clean, dry environment not above 120º F.

Summary

We must remember to always wear our hard hats. If they are sitting at a desk, on a work bench, or in a truck, they are definitely not going to protect us.

It goes without saying that our head is worth protecting. A single head injury can handicap us for life or may be fatal. Injuries to those of us not wearing hard hats can come from virtually every angle—while looking down, looking straight ahead, and when bumping into stationary objects.

Head up, eyes open, and hard hat on!

This article originally appeared in the July 2015 issue of Occupational Health & Safety.