BSEE Test Simulates Major Underwater Blowout

The agency announced that its Ohmsett facility conducted a subsurface test at an unprecedented flow rate late last month.

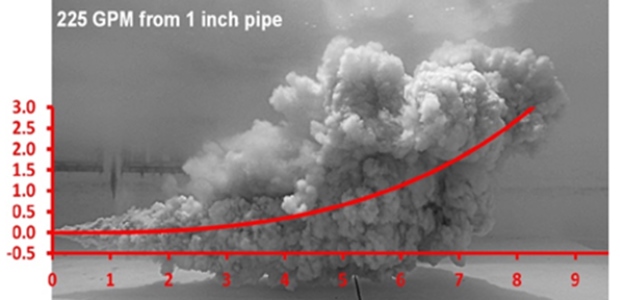

The federal Bureau of Safety and Environmental Enforcement announced that its Oil Spill Response Division sponsored large-scale testing by the National Energy Technology Laboratory late last month to calculate flow rates from a subsea blowout. The tests took place Oct. 27-29 at Ohmsett, BSEE's National Oil Spill Response Research and Renewable Energy Test Facility in Leonardo, N.J., which was able to produce a subsurface flow of 30,000 barrels a day, the largest flow rate ever produced during an intentional hydrocarbon release.

The research is scheduled to be completed by June 2015 and aims to develop a remotely operated vehicle-mounted camera and software package that can calculate the flow rate of a blowout by tracking the physical features of the plume. BSEE's release said faculty and students from the New Jersey Institute of Technology and Canada's Department of Fisheries and Oceans installed instrumentation to capture droplet size distributions, oil density throughout the plume, droplet velocities, and water samples, all of which NJIT will use to refine its VDROP model -- a comprehensive model for droplet formation of oils and gases in liquids.

Ohmsett is the largest outdoor saltwater wave/tow tank facility in North America and is the only facility where full-scale oil spill response equipment testing, research, and training can be conducted in a marine environment with oil under controlled environmental conditions, according to the agency.