Top Five Ways to Reduce Fall Hazard Risk

This is key: Once the right risk assessment data is collected, it should be used to implement a long-term fall protection abatement program.

- By Thomas Kramer

- Jul 01, 2013

Despite state-of-the-art equipment and an abundance of fall protection information, fatal falls still occur every day in our country.

The problem: Fall protection is complex. The numerous regulations, standards, equipment options, training sources, and other safety priorities make it challenging to address. Plus, fall protection presents two conflicting realities: Significant fall incidents don't happen often, but when they do occur, they're catastrophic and costly.

Managing the major risks presented by falls is a smart and ethical business investment -- in addition to a legal requirement. But, with all the complexities, how do you effectively reduce fall hazard risk?

More than 20 years of experience in the fall protection industry has shown that five primary methods can help effectively reduce risk for workers at heights.

#1: Apply Prevention through Design

The first and best way to reduce fall hazard risk is to eliminate it before it's ever created. This concept has had various names over the years, but the common name is Prevention through Design (PtD). With PtD, fall hazards are identified and addressed during the programming and design phase of new buildings and processes.

Evaluating and implementing safety measures early in a project ensures optimal safety for workers -- from construction into operations and throughout ongoing maintenance. When safety professionals and front-line employees who know the work best are brought in at the beginning of a project, safety concerns can be addressed within the project's original timeline and budget.

Developing a PtD program saves money, time, and effort and creates positive momentum for a fall protection program. Research studies and project applications have proven that waiting to address hazards will cost more money while leaving fewer options for abatement.

The impact to bottom-line cost can be dramatic. For example, the consultant fees for one PtD project would have been spent to erect scaffolding to solve fall protection issues after project completion -- in one area, one time. Through the life of this project, the scaffolding would have been erected an additional 20 times, at significant cost and risk to workers. By applying PtD, the organization achieved a significant order of magnitude cost savings, in addition to substantial improvements to worker safety and productivity.

PtD programs also consistently reduce overall operating costs. When fall hazards are eliminated or managed through engineering control solutions, fewer fall protection issues are present through the life of a facility. This translates to fewer equipment purchases, less training, and a reduced number of elements to manage.

So if organizations have to spend more but do less without PtD, why aren't more organizations doing it? First, most organizations are in reaction mode, responding to the hot issue of the day rather than foreseeing issues that will present risk years down the road. Another reason organizations don't apply PtD is simple lack of knowledge. In January 2012, ANSI published the Z590.3 standard, which provides guidance for developing and implementing a PtD program. The guidance provided by this standard minimizes the barrier for entry for employing PtD to proactively reduce risk.

#2: Perform and Use a Fall Hazard Risk Assessment -- the Right Way

It's impossible to reduce fall hazard risk if you don't know where it is. A valuable fall hazard risk assessment identifies risk and quantifies it so it can be ranked in comparison to other risks. The industry is full of different methods to identify and evaluate risk, from simple risk codes to complex mathematical risk formulas. Unfortunately, many of the methods do not provide enough granular information to be useful in effectively reducing risk. Or they are provided by people whose motivation is to sell fall protection equipment -- not to reduce risk.

By using detailed data to rank risks, an effective assessment focuses a fall protection program on the highest risks. So, rather than devoting resources to the most obvious hazards, organizations can systematically identify, evaluate, and control fall hazards. And by directing the available budget to the highest-risk items, organizations can achieve maximum risk reduction for their investment.

During a comprehensive fall hazard risk assessment, data is gathered on all fall hazards. The data are analyzed to determine the probability and severity presented by each hazard. In terms of probability, a variety of factors must be considered: frequency of task, exposure time, number of workers exposed, and likelihood of falls based on external influences. The severity is measured by determining fall distance and likely obstructions impacted during a fall. The resulting data are then organized into a prioritized list of hazards. This list can be organized by location, maintenance task, and type of solution proposed -- or in any other way that helps the organization manage abatements. Once fall hazards and the potential risks associated with them are identified, evaluated, and ranked, leadership can use the information to create a validated budget, schedule, and abatement strategy.

This is key: Once the right risk assessment data is collected, it should be used to implement a long-term fall protection abatement program. Because it's impractical to address every fall hazard immediately, the prioritized list provides guidance on what, when, and how to abate hazards. Using this list to manage a fall hazard program allows continuous tracking of your hazard abatement efforts.

After performing a comprehensive fall hazard risk assessment method, an overwhelming list of hazards is transformed into a manageable plan, with a beginning and end point. Program managers can use this information to report metrics on the amount of risk reduced for a given investment.

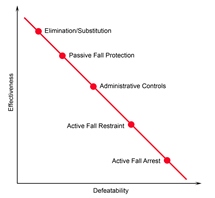

The Hierarchy of Controls gauges abatement solutions based on effectiveness and defeatability. PPE solutions are at the lowest point on the Hierarchy.

The Hierarchy of Controls gauges abatement solutions based on effectiveness and defeatability. PPE solutions are at the lowest point on the Hierarchy.

#3: Use Less PPE

Equipment is one of the most visible aspects of a fall protection program, and organizations often devote significant time, money, and resources to applying personal protective equipment (PPE). Despite its prevalence, however, PPE should always be the last choice for a fall protection solution.

While PPE solutions are appropriate in many circumstances, they should not be the first or only abatement option considered. Experience has shown that, collectively, people simply do not use fall protection equipment properly enough for it be effective in reducing risk. On the other hand, engineering controls, such as guardrail, require no action to work properly.

In the best case, donning equipment creates complacency. In the worst case, it creates a false sense of security. The primary downside to relying on PPE systems is that they have so many opportunities to fail. PPE systems are only as strong as their weakest link. Even a properly designed system can fail if any of the following issues is present:

- Inadequate anchorage

- Inadequate fall clearance

- Equipment misuse

- Incompatible component

- Lack of procedures

- Improper training

Minimizing the use of PPE can also save money in the long term. While PPE solutions are typically more cost effective in the short term, they also come with significant recurring costs stemming from training, retraining, inspection, replacement, and higher risk. When you use equipment, you are essentially paying from the original purchase until it is no longer used.

Finally, a rarely referenced OSHA standard directive (STD 1-1.13) provides guidance on when PPE can be considered or whether engineering controls must be applied. The standard directive states that frequent tasks -- occurring more than once every two weeks or for more than four hours during a four-week period -- require the use of engineering controls, such as guardrail.

#4: Focus on Certified Systems -- Not Equipment

With the publication of the ANSI Z359 family of standards, a new emphasis is placed on certified equipment components. While safety managers and users may boast that their equipment meets the latest ANSI Z359 standards, the more important point is whether they can document if the entire fall protection system is certified.

The ANSI Z359.6 standard provides guidance on how to certify a fall protection system. The ANSI guidelines require documentation that proves a system will do what it is intended to do. The intent, of course, is to keep workers from hitting the ground. To determine if a system can be certified, the standard outlines several elements that must be reviewed and documented.

Ideally, the certification of a fall protection system begins during design and continues through installation and use. This is important because documentation should be gathered at each step. Having this documentation also facilitates the formal inspections required by equipment manufacturers, as well as system re-certification that ANSI Z359.6 requires every five years at a maximum.

While critics may say that certification documentation is unnecessary paperwork and expense, it is the only way to ensure that a system is designed and used properly. Many organizations have been shocked to find out the systems they invested in are not capable of supporting a fall protection load due to improper design, installation, or use limitations. In one instance, the fall protection anchors that were supposed to withstand 5,000 pounds pulled out of the structure with simple hand tools due to faulty installation.

When you require your workers to use active fall protection systems, ask yourself this: Would you take a fall from this system? Are you that confident in the design, installation, equipment, and inspection? If you aren't willing to take the fall, you shouldn't ask your workers to, either.

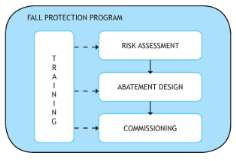

Regular, ongoing training supports the other major elements of a fall protection program and increases the effectiveness of each step.

Regular, ongoing training supports the other major elements of a fall protection program and increases the effectiveness of each step.

#5: Provide Quality Training

While training is listed as number 5 on this list, it should be the first step toward instigating changes in behavior to reduce risk. Training is required by OSHA regulations and other standards, so it is an essential part of a fall protection program. But, for training to be effective, it should be more than a requirement that simply checks a box. The goal of fall protection training is to change behavior.

To truly impact a safety program, training needs to include more than just instruction on regulations and equipment use. Participants need the skills and tools to solve fall protection issues before they arise so they don't rely on less-effective, reactive approaches in the field.

It is also important to ensure that training providers are qualified to provide real value for an investment in training. Programs that adhere to the ANSI/IACET standard for continuing education and training follow a proven model for developing effective and valuable training programs, primarily for adult learners. Finding training providers that are authorized by IACET will enrich the training experience, and in turn, the resulting changes in behavior. Because adult learners have a variety of learning preferences, it is also important to use a variety of teaching methods to enhance training. Combining lecture, multi-media applications, and hands-on exercises increases ownership, understanding, and the retention of critical material.

No matter the training approach, it must be customized to the workers and to their unique environments and responsibilities. Regular, ongoing training supports the other major elements of a fall protection program and increases the effectiveness of each step. Without effective training, an investment in design and equipment can be easily wasted through misuse.

When fall protection issues are properly addressed, the result is increased safety and reduced risk. By working toward the ideal presented by these five methods, a fall protection program achieves risk reduction by balancing cost efficiency, safety, and usability.

This article originally appeared in the July 2013 OHS issue of Occupational Health & Safety.