Creating a 'Comfort Zone' for Emergency Equipment Water Temperature

Tempered water has been a hot topic of late, but just as many installations need cooling of high-temperature supply water.

- By Samantha Hoch

- May 01, 2018

Moving water transfers heat, either increasing the temperatures of the objects it contacts or decreasing them. Heat transfer, via moving water, made twentieth century man more productive and more comfortable. It sped up transportation and made a wealth of innovative products possible. But while the physical properties of heat transfer via water movement can certainly be beneficial, there are many instances when temperatures must be controlled within a high and low range to avoid injury. For many years, industrial emergency equipment was not one of those instances. The water that flowed through emergency showers and eyewashes was subject to climatic, source affected, and other ambient variables that could raise it to injurious temperatures or lower it to downright freezing temperatures.

Municipally supplied water, when running for a sustained period, tends to cool down or even heat up, eventually approaching its source point temperature. And, by the same token, water subjected to hot or cold ambient temperatures in manufacturing plants or elsewhere can become dangerously hot or cold. Presently, OSHA, at 29 CFR 1910.151(c), requires the availability of suitable first aid treatment facilities. Specific direction is given indicating that "suitable facilities for quick drenching or flushing of the eyes and body shall be provided."

While the definition of "suitable" was mostly left up to the specifier in the past, the current ANSI/ISEA Z358.1-2014 standard provides much greater clarity. ANSI mandates a water delivery temperature range defined as "tepid." This is clarified as a 40-degree temperature range for flushing fluids spanning from 60 degrees F to 100 degrees F [16 degrees C to 38 degrees C]. Yet, no source information proves that 60 degrees F for 15 minutes in potentially freezing outdoor conditions will not lead to hypothermia. Nor is there supporting documentation to verify that 100 degrees F would not scald or further injure the delicate eye tissues or skin.

The thought of an injured worker short-cutting the required emergency equipment use cycle because the water is too cold or hot has led to the notion of the "Comfort Zone"—a revised outlet water temperature range that ensures comfortable, non-injurious use for the full 15-minute use cycle.

Revisions to the ANSI/ISEA Z358.1 standard have occurred on a somewhat routine basis. Published in 1981, the standard was updated in 1990, 1998, 2004, 2009, and most recently in 2014, with the expectation of another update on the horizon. It is suggested that a revised water temperature range between 70 degrees F and 95 degrees F can help ensure medically effective results and provide that best practice comfort zone. Increasing the minimum flushing fluid temperature to 70 degrees F can encourage users to use the equipment for the full 15-minute flush cycle, protect against cold shock that could lead to cardiac arrest, and advocate for the removal of contaminated clothing. Decreasing the maximum temperature to 95 degrees F will help avoid temperatures known to harbor specific bacteria growth, prevent scalding of the eyes and skin, and reduce the chances of an increased chemical reaction.

So, how do you ensure a facility's equipment falls within the comfort zone? For the sake of this discussion, we will assume that the plant has sufficient emergency equipment in the appropriate locations and that the comfort zone approach is being added to the existing emergency equipment assets.

Let's consider the most appropriate steps to be taken:

1. Ascertain your actual inlet water temperature range and compare it to the desired range. This involves checking the initial and sustained temperature readings at the various emergency equipment sites located throughout the facility. Because conditions can change from location to location, the chore of checking each shower and eyewash is the safest bet. Don't forget the impact of seasonality on water temperatures. It may be necessary to check at several times during the year.

2. Determine the overall changes needed. If initial temperatures are either too hot or too cold, while sustained temperatures are within the ANSI mandated temperature range or even the recommended comfort zone, consideration of a re-circulation system is appropriate.

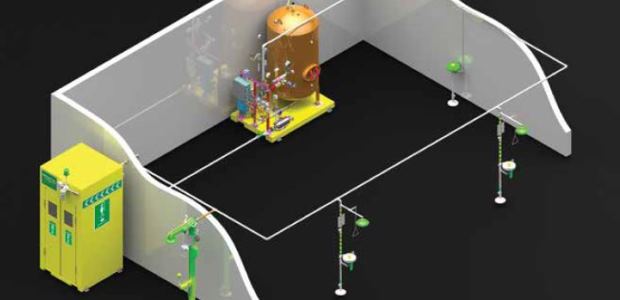

If sustained use temperatures fall outside of the temperature parameters, you may require warming technologies, cooling technologies, or, in certain areas and circumstances, both. In most instances, these types of systems can be sized to handle multiple showers/eyewashes each. Specific applications should take into account the volume of shower and eyewash locations to be included in each loop, the maximum distance between components, and the impact of exposure of warmed or cooled pipes to ambient air temperatures. It is highly recommended that specifiers work with eyewash and shower manufacturers directly to determine the appropriate system, given your specific geographic location, processes, temperatures, and layout/equipment locations.

It should also be noted that while tempered water—meaning warming cold water—has been a hot topic of late, just as many installations need cooling of high-temperature supply water. Elevated temperatures can come from several sources, including high ambient temperatures, exposure to process heat, or excessively high supply temperatures.

3. Identify the number, required location(s), and sizing of the thermostatic mixing valve(s). This applies only to tempering water or warming sustained-use cold input water prior to emergency equipment use. Temperature control for cooling operations is handled integrally within the system’s chiller unit.

The brain of a warming system is its thermostatic mixing valve. This device ensures that the safety equipment safely receives water at the required temperature. A good thermostatic mixing valve is actually a system of valves, typically designed by safety equipment manufacturers since they understand their equipment and their specific flow rate requirements. Specifiers are cautioned to do their homework well with respect to selection of the proper valves for your specific needs.

4. Determine your hot and/or cold water source. In sizing the tempered water system for any particular application, providing a source for sufficient quantities of water is essential. Recent advancements in instantaneous hot water heaters have made these products practical for use in emergency equipment applications, especially where space for traditional hot water heaters and hot water storage tanks is limited.

5. Consider the maximum simultaneous usage. Always work to the maximum use, worst-case volumes. Booster and/or re-circulation pumps, as well as storage tanks, may be necessary to ensure the availability of the maximum demand volume of tempered water. A variety of products are available to fill these needs.

The science of emergency equipment design and specification continues to advance rapidly, and the clear winners are the specifiers who stay "on top" of the advancements and the employees who are protected by them. Establishing and maintaining a best practice comfort zone for water temperature delivery provides everyone the maximum peace of mind.