Keep Lifts Between the Knees and Shoulders

When lifting an object to above shoulder height, the core and stabilizer muscles become less efficient, so we change our body mechanics and the risk of shoulder injury increases dramatically.

- By Allan Brown

- Feb 01, 2018

How did this lifting range come into existence? Some might say experience and logic got us here. Actually, this guideline was developed through historical research done by the National Institute for Occupational Safety and Health (NIOSH) using mechanical models and understanding the mechanism of injury.

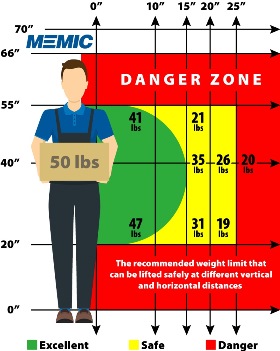

The NIOSH lifting equation1 is used to predict the risk of injury based on the weight being lifted. The equation uses a load constant of 51 pounds. This was the starting load that 99 percent of male and 75 percent of female workers could handle safely in perfect conditions. However, perfect conditions don't exist in our manufacturing and manual lifting worlds.

The equation accounts for these imperfections (such as reaching and vertical distance) and chisels away at the 51 pounds as risks increase. Once all considerations are accounted for, the final recommended weight limit is calculated. This is often something less than 51 pounds.

The health care industries as well as some manufacturers, are starting to use 35 pounds as a standard. It’s a basic recommendation that doesn't account for all risks when lifting.

Why Knee and Shoulder Height?

At shoulder height, the dynamics and forces around the shoulder change and become poorer and weaker. According to a review of literature by Rhode and Rhode2 titled "Occupational Risk Factors of Shoulder Tendon Disorders 2015 Update," when lifting an object to above shoulder height, the core and stabilizer muscles become less efficient, so we change our body mechanics and the risk of shoulder injury increases dramatically.

The graphic above illustrates safe lift zones and appropriate weights in those zones. The green area is the best zone often referred to as the power zone. The red zone is the no lift zone and is appropriately above shoulder and below knee height. Additionally, the farther a worker reaches from the body, the lesser the weight safely handled (yellow zone).

You can see why 35 pounds became the health care industry standard and a good recommendation for all lifting environments.

At the lower end of a lift, moving below the knee increases the risk and exposure to the back, especially for the lumbar region. Research completed by Al Nachemson3 illustrated the changes in disc pressure with different activities. Lifting activities greatly increase the disc pressure. Better body mechanics reduce the force, and keeping the load off the floor in an upright position reduces the force further.

Safe Lifting Guidance

Here's a fact that will make you pause before you lift from the floor. Bending at the waist and reaching to the floor with no weight in the hands increases the pressure in the lumbar disc to approximately 1,000 inch pounds.

NIOSH recommends limiting lumbar disc pressure to no greater than 770 inch pounds. Forces beyond 770 inch pounds begin to physically change the health of the disc. Lifting properly can reduce the force, but proper technique is a skill rarely mastered or used by people in a dynamic work environment.

Through these studies, we know the safest lift range is between standing knee and shoulder height. This is a basic guideline not taking into consideration reaches and twists away from the body, as well as coupling (grip). Work environments outside these ranges increase the risks of shoulder and back injuries.

Here are a few simple considerations:

- Keep lifts between knee and shoulder height.

- Limit weight to 35 pounds and consider lift assist devices, such as vacuum lifts for greater loads.

- Avoid placing work on the floor. Double up pallets to raise load platform.

- Consider dynamic pallet lifts to keep the load in the best position.

- Anything lifted manually over 35 pounds should be a two-person lift.

References

1. https://na.bhs1.com/osha-uses-niosh-lifting-equation-address-ergonomic-hazards-manual-material-handling-tasks/

2. http://medcraveonline.com/MOJOR/MOJOR-03-00104.pdf

3. http://fonar.com/pdf/spine_vol_24.No.8.pdf

This article originally appeared in the February 2018 issue of Occupational Health & Safety.