DOT Seeks to Quantify Rail Car Retrofits

According to the BTS notice, there are approximately 400 tank car facilities in the United States currently registered or certified to build or modify tank cars, but only about 140 have the capacity to modify or build to the 117 or 117R specifications.

DOT's Bureau of Transportation Statistics (BTS) has published a Federal Register notice as it seeks approval for an information collection about tank car facilities, with the goal of obtaining an estimate of tank cars projected to be modified or built to new and safer DOT standards. Comments on the proposed collection are due on or before May 22.

To submit them, visit www.regulations.gov and search for Docket No. DOT-OST-2017-0010.

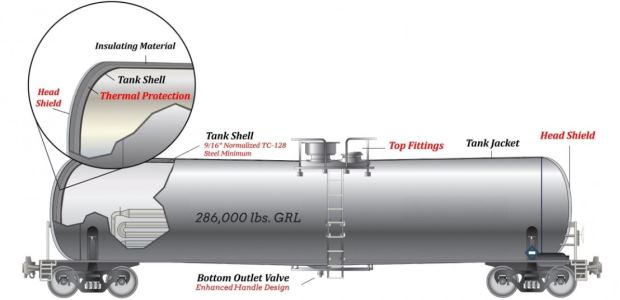

Section 7308(c) of the Fixing America's Surface Transportation Act directs the secretary of Transportation to conduct an annual survey of tank car facilities to obtain an estimate of tank cars projected to be modified or built to DOT Specification 117 or 117R. DOT published a rule two years ago that established a schedule for retrofitting older tank cars that carry crude oil and ethanol.

New tank cars constructed after Oct. 1, 2015, are required to meet the Specification 117 design or performance criteria for use in High-Hazard Flammable Trains, and existing tank cars must be retrofitted in accordance with the DOT-prescribed retrofit design or performance standard for use in such trains.

According to the BTS notice, there are approximately 400 tank car facilities in the United States currently registered or certified to build or modify tank cars, but most of them don't have the capacity to modify or build to the 117 or 117R specifications. DOT estimates that, at most, 140 tank car shops do have the required capacity to build or modify to the requirements.