Slip Resistance

To date no study has been performed that defines the safe threshold COF for a specific tribometer for all combinations of footwear, contaminant, and floor type.

- By Mark Blanchette, Bert Spiller

- Nov 01, 2016

Slip resistance is the most often discussed topic involving safety footwear. To best understand how slip resistance relates to safety, one needs to consider the range of factors that collectively have an effect on slip resistance. The ongoing scientific research on slip resistance aims to identify these factors, with the ultimate purpose of establishing safety through understanding. Although much has been studied, written, and reviewed, given the range of variables that effect slip, further research is still necessary. Using the information available and a well-intended plan of review, this [article] will assist in making informed recommendations for footwear that best fits the specific needs of the intended user. Given the number of contributing factors to slip events, and the inherent elements of randomness and unpredictability with which they occur, it is important to establish that no testing, either human subject or mechanical, can accurately predict with 100% certainty the required level of safety so that slips will not occur.

The shoe-floor interface is the driving factor in providing secure footing. Contaminants at the shoe-floor interface can affect shoe-floor contact and therefore prevent optimum shoe-floor interaction. Additional factors that contribute to slip resistance include: walkway condition & maintenance, area lighting, biomechanics of the ambulator, age & functional status of the ambulator, footwear type and condition, and others. Within this [article], the definitions of the terms "slip resistance," "slip resistant," and "walkway tribometer" are from ASTM F1646.

Slip resistance, n—the relative force that resists the tendency of the shoe or foot to slide along the walkway surface. Slip resistance is related to a combination of factors including the walkway surface, the footwear bottom, and the presence of foreign materials between them.

Slip resistant, adj—the provision of adequate slip resistance to reduce the likelihood of slip for pedestrians using reasonable care on the walking surface under expected use conditions.

Walkway tribometer, n—any apparatus used to measure the friction forces acting at an interface between a walkway surface and shoe material. This is the definition of walkway tribometer within ASTM F2508.

The Questions Most Often Asked

What is a safe coefficient of friction (COF)? What is the best method of testing slip resistance? How do I compare one test method’s results to another? The information throughout this [article] serves as a guide to answering these questions and why there are no exact answers.

Tribometers are mechanical instruments that purport to measure the COF between a test foot and floor in order to assess a pedestrian’s risk of slipping while walking. Many different types of walkway tribometers exist, and empirical research has shown that not all tribometers measure the same COF on the same surface. For example, a COF of 0.3 obtained on a particular tribometer will not correlate to 0.3 of another tribometer. The "classic" laws of friction formulated in the 17th century stated that COF was independent of contact area and velocity; however these laws are not obeyed by viscoelastic materials like the synthetic polymers used in most shoe outsoles, tribometer test feet, and certain flooring materials. In the presence of these polymers, the parameters of peak force, loading rate, pressure, and time of contact between the tribometer test foot or shoe and test surface influence tribometer COF values. Because these parameters diverge widely between tribometer types, no single safe threshold COF value can be defined that encompasses all tribometer results. To be meaningful a safe threshold COF value would have to be associated with a specific calibrated tribometer, test foot material, and test method. To date no study has been performed that defines the safe threshold COF for a specific tribometer for all combinations of footwear, contaminant, and floor type.

Available Friction and Utilized Friction

This purpose of this section is to provide a basic education as to why slips occur. As the [article] progresses, the topics of slip resistance testing and applicable standards will be covered. The information provided is an introduction into the complex and multivariate event that is slipping.

Background

The function of footwear is to provide protection, safety, comfort, and enhanced performance during dynamic and static activities. With respect to safety and performance, it is essential that footwear deter slipping. Slipping has been reported as being responsible for 62% of underfoot accidents in the workplace. Additionally, slips are considered to be the primary cause of falls.

In 2008, slips and trips were responsible for 6.9% of occupational sprain and strain injuries and accounted for 3% of all occupational injuries and illnesses. The Bureau of Labor Statistics reports that falls on the same level and falls to a lower level have incidence rates per 10,000 full-time workers of 18.0 and 7.3, respectively. By the year 2020, it has been estimated that slip and fall-related injuries will approach 17 million annually with associated health care costs in the billions. To prevent slips and slip-related injuries, it’s necessary to understand the conditions which increase slip risk and the terminology.

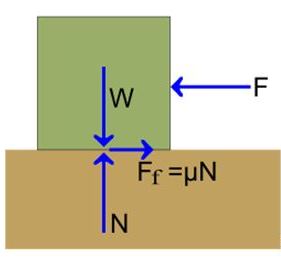

Available Friction. Why do slips occur? To discuss why slips occur, first the role of friction must be introduced. Friction can simply be defined as a force that opposes motion. For example, if you drag the sole of your shoe along a dry tile floor, you'll likely feel a resistance to that motion, your shoe may even squeak. The resistance you feel is actually friction. Refer to Figure 1.

The weight (W) of the block is equal to the vertical force (N) acting upwards. This simply represents Newton’s 3rd Law of motion, which states that for every action there is an equal and opposite reaction. If a force (F) is applied to the block, motion of the block is resisted by the friction force (Ff). The friction force (Ff) is proportional to the vertical force (N), where Ff = µN. The coefficient of friction, mu (µ), is commonly referred to as available friction. With respect to slip and fall-related literature, available friction or the coefficient of friction is abbreviated COF.

The weight (W) of the block is equal to the vertical force (N) acting upwards. This simply represents Newton’s 3rd Law of motion, which states that for every action there is an equal and opposite reaction. If a force (F) is applied to the block, motion of the block is resisted by the friction force (Ff). The friction force (Ff) is proportional to the vertical force (N), where Ff = µN. The coefficient of friction, mu (µ), is commonly referred to as available friction. With respect to slip and fall-related literature, available friction or the coefficient of friction is abbreviated COF.

Available friction = COF

A larger COF represents a larger friction force and a greater resistance to motion. Conversely, a lower COF represents a smaller friction force and a lower resistance to motion.

Available friction is the friction provided by the environment, more specifically the shoe-floor interface. Both the floor and the shoe can influence available friction for a variety of reasons. The friction measured at the shoe-floor interface can be represented by either static or dynamic coefficients. The static coefficient of friction represents the friction requirement to deter slip onset, whereas the dynamic coefficient represents the friction requirement to deter slip continuation and uncontrollable foot slide, i.e. slipping. The dynamic coefficient of friction is most often associated with descriptions of available friction. Often, the term available friction is used interchangeably with slip resistance. For example, assessing the slip resistance of a shoe sole means determining the amount of available friction it provides or its COF.

Utilized Friction. Human walking, or gait, has two distinct phases: stance and swing. The stance phase refers to when a reference foot is in contact with the ground while the swing phase refers to when that same reference foot is off the ground. During walking, slips that result in falls typically occur in early stance (when the foot first hits the floor) as body weight is transferred onto the lead limb. The ground reaction forces (GRFs) during this period of weight acceptance are critical to determining if the available friction provided by the shoe-floor interface will be sufficient to prevent slips. Ground reaction forces are the equal and opposite reactions (Newton’s 3rd Law) to a person’s body weight. These are the forces that act from the floor back up into the body. Important to note, GRFs are measured in a laboratory setting by having a person walk over a device called a force plate (Figure 2).

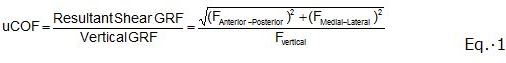

Ground reaction forces occur in 3 directions: vertical, anterior-posterior, and medial-lateral. The vertical GRF acts directly upwards from the floor. The anterior-posterior GRF acts forward and backward. The medial-lateral GRF acts left and right. Measuring GRFs in a lab setting is a useful tool to determining the conditions that elicit slips. Ground reaction force data are used to calculate the second type of friction in the context of slips and falls, utilized friction. Utilized friction (abbreviated uCOF) is defined as the friction force required to maintain motion without slipping. It is calculated as a ratio of resultant shear force to the vertical ground reaction force (Eq. 1). The resultant shear force is sum of the anterior-posterior and medial-lateral GRFs.

Ground reaction forces occur in 3 directions: vertical, anterior-posterior, and medial-lateral. The vertical GRF acts directly upwards from the floor. The anterior-posterior GRF acts forward and backward. The medial-lateral GRF acts left and right. Measuring GRFs in a lab setting is a useful tool to determining the conditions that elicit slips. Ground reaction force data are used to calculate the second type of friction in the context of slips and falls, utilized friction. Utilized friction (abbreviated uCOF) is defined as the friction force required to maintain motion without slipping. It is calculated as a ratio of resultant shear force to the vertical ground reaction force (Eq. 1). The resultant shear force is sum of the anterior-posterior and medial-lateral GRFs.

Why Slips Occur

Unperturbed ambulation (walking, turning, running etc.) requires that the available friction at the shoe-floor interface exceed the peak utilized friction of the person walking. Therefore, slips occur when an individual’s peak uCOF exceeds the available friction provided by the shoe-floor interface. The greater a person’s uCOF is compared to the available friction provided by the shoe-floor interface, the greater the likelihood of a slip occurring. Conversely, the greater the available friction is compared to a person’s peak uCOF, the lesser the likelihood of slip occurring. This applies for any shoe-floor-contaminant scenario. Previous research has shown that numerous factors can affect uCOF, including walking velocity, activity, age, sex, shoe sole hardness, and shoe type. Some scenarios that increase utilized friction are: walking fast vs. walking slowly, walking in high heel shoes vs. low heel shoes, walking in soft sole shoes vs. hard sole shoes, running vs. walking, and running vs. cutting.

To deter a slip event from occurring, the available friction at the shoe-floor interface must exceed the person’s uCOF. During walking, the peak uCOF has been reported to range from 0.15 to 0.31 for normal speeds. However, more dynamic activities like running and cutting utilize more friction to perform without slipping, ranging from 0.48 to 0.83. A general rule of thumb is that the more dynamic an activity, the more friction that is required to perform it without slipping.

Whole Shoe Testers

Various portable tribometers (slip testers) were originally designed for the testing of walkways. Walkway tribometers provide useful information, primarily as it relates to the friction attributes of the walkway when utilizing a pre-prescribed test foot sized for a particular tribometer (example: 3x3 inch test foot of the Mark II). In the past, due to the absence of alternative test methods, and presently to some degree, safety professionals along with footwear material providers and footwear manufacturers relied on walkway tribometers to test the COF of footwear soling materials. Utilizing such testers and test methods may be helpful as a means of ranking materials. However, attempting to relate the results from tribometer testing to testing of an actual footwear bottom has been called into question. Concern has also been raised that results based on methods intended for walkway testing often do not take into consideration the design attributes of the footwear bottom. For example, the footwear design found at the rear area of the heel, the area of the shoe which first comes in contact with the walkway surface during walking, is most often not the same tread pattern found in the forefoot of footwear. Furthermore, to accommodate some tribometer designs, it is often necessary to extract the test foot sample from the forefoot area of the footwear outsole (typically a 3x3 inch square or circular test foot).

In 2009, ASTM International and SATRA signed an agreement which in 2011 brought about the balloting, approval, and publication of ASTM F2913 Standard Test Method for Measuring the Coefficient of Friction for Evaluation of Slip Performance of Footwear and Test Surfaces/Flooring Using a Whole Shoe Tester. ASTM F2913 allows for the testing of footwear in three differing test modes: heel contact, shoe flat contact, and toe contact. The test method also allows for the introduction of various walkway surfaces, traditional and non-traditional, as well as the controlled introduction of contaminants.

Considerations for Purchasing Safety Footwear

If you are the safety director responsible for buying footwear for the workplace there are two things to consider. 1) What relevant workplace information do you need to know and 2) What questions do you need to ask a potential supplier. First, you should have a comprehensive understanding of the environment in which the footwear will be used, including: the types of floor surfaces, exposure to potential contaminants and activities to be performed. Providing the supplier with this information will allow for a more appropriate recommendation for slip deterrent footwear. Second, you should be able to ask a supplier questions about their footwear recommendations. Inquire about “what if” scenarios; such as, what if a person steps in oil (or other contaminant)? What activities are these shoes recommended for? Has the slip resistance of these shoes been tested and if so, what testing protocol was used for testing, how did the shoes rate compared to other styles, and do they have a written report of the results? Is the outsole designed for durability while maintaining its functional attributes? Are there any limitations of these shoes? Knowledge of the workplace environment in which footwear will be worn in combination with coordinating with a supplier regarding the safety and application of workplace footwear will greatly decrease the likelihood of slips and slip-related injuries from occurring.

This article originally appeared in the November 2016 issue of Occupational Health & Safety.