GAO Faults Energy Department on WIPP Restart Process

Nuclear waste disposal activities at the facility have been delayed about nine months and cost about $64 million more than expected because the agency did not follow best practices in developing those estimates, a new report says.

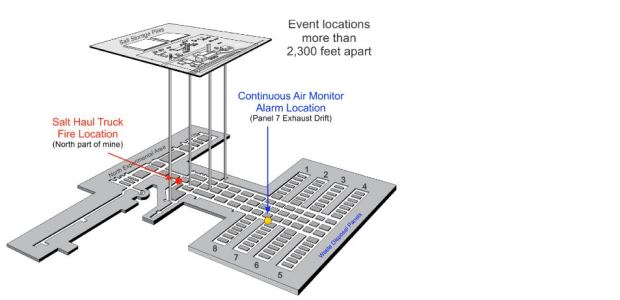

The U.S. Government Accountability Office issued a report Aug. 4 on its examination of the U.S.Department of Energy's process for resuming operations at the Waste Isolation Pilot Plant (WIPP), the transuranic waste disposal site outside of Carlsbad, N.M. Operations there have been suspended since two serious incidents in February 2014, a salt haul truck fire and a radiological release from a waste container, incidents that exposed workers to smoke and radiation. The GAO report says the resumption has seen a cost increase of about $64 million and a delay of nearly nine months partly because DOE did not follow all best practices in developing the cost and schedule estimates. In particular, its schedule did not include extra time, or contingency, to account for known project risks.

DOE estimated it would restart waste operations in March 2016, but it approved new estimates in January 2016 that added 8.5 months to the schedule, extending the restart to December 2016.

According to GAO's report, DOE did not provide evidence of having an independent cost estimate to validate the revised estimate and didn't follow all best practices for cost and schedule estimates in part because DOE does not require that its cleanup operations follow them. Nor did DOE follow all best practices in analyzing and selecting an alternative for the new ventilation system at WIPP that was planned in order to result full operations. "As a result, DOE's analysis was not reliable and DOE cannot be confident that the alternative it selected in December 2015 will best provide the needed capabilities at WIPP," GAO reported.

WIPP is the only deep geologic repository for the disposal of U.S. defense-related nuclear waste. GAO has recommended that DOE require cleanup operations to follow best practices for cost and schedule estimates, and DOE has concurred with that and other recommendations.

After the incidents, DOE issued a Preliminary Notice of Violation to Nuclear Waste Partnership, LLC for violations of DOE worker safety and health and nuclear safety requirements and the agency's National Nuclear Security Administration issued a PNOV to Los Alamos National Security for violations of DOE's nuclear safety requirements. Nuclear Waste Partnership, LLC is the management and operating contractor for WIPP, while Los Alamos National Security is the management and operating contractor for NNSA's Los Alamos National Laboratory in Los Alamos, N.M. DOE had confirmed 13 workers' radiation exposures. DOE reported that the violations by LANS were associated with processes used by LANS to package and remediate transuranic waste drums, one of which was linked to the WIPP radiological release.

And DOE installed a wireless system underground at WIPP that allows two-way communication for both talk and text, with audible and flashing alarms, so personnel can immediately signal the Central Monitoring Room during an emergency. The system provides real-time tracking of all personnel entering the WIPP underground.