Help Protect Hard-Working Hands from Occupational Skin Disorders

Just one case of occupational dermatitis can cost an employer approximately $3,500 in workers' compensation claims and an average disability of 23.9 days, according to the Journal of the American Medical Association.

- By Andreas Klotz

- Feb 01, 2016

Hard-working hands keep businesses running every day. Although some believe that cracked and irritated skin is proof of hard work, it is actually a sign of a potentially serious skin condition. During each work day, your employees are exposed to irritating substances and work conditions that can be harmful to their skin. From dust, powders, and airborne substances to abrasion from tools, components, and materials they handle, your employees face many conditions that can lead to work-related skin disorders.

The three main types of work-related skin disease include:

- Irritant contact dermatitis: This disorder has a cumulative effect that can sometimes cause pain and discomfort quickly. Other times, it can build up over a period of many years. Although very painful, this disorder is curable.

- Allergic contact dermatitis: This disorder can be immediate or accumulate over time. An employee may be in contact with a substance or material for many years before becoming sensitized. Once sensitized to a substance or material, the employee is sensitized for life, with no cure. Employees will experience pain and discomfort immediately upon contact with the substance or material to which they are allergic.

- Skin cancer: This is caused by contact with ultraviolet (UV) rays or carcinogenic materials, such as used mineral oils (engine/machine), coal tars, and pitches.

Warning Signs

Unfortunately, most work-related skin problems are not reported, partially because workers may not realize that their skin condition is work related. Some prefer not to mention the issues because they are worried about possible repercussions from their employer. It is likely that the number of unreported work-related skin issues is 50 to 70 times higher than the reported cases. The U.S. Bureau of Labor Statistics found that 75 percent of patients with occupational dermatitis developed chronic skin disease.

The symptoms and seriousness of occupational dermatitis vary widely. The first symptoms of a looming skin disorder include itching, flaking, and/or scaling skin; sore, cracked and/or bleeding skin; swelling of hands or fingers; and blisters or welts on hands/fingers. Occupational skin disorders (OSDs) can easily be averted at this early stage by instituting protective measures and by paying more attention to the skin.

A skin disorder goes beyond cosmetic concerns. It can also become a financial burden to an employee and employer. According to the Centers for Disease Control and Prevention, OSDs are the most common type of workplace illnesses, with estimated costs (including time away from work, reduced productivity, and workers compensation claims) exceeding $1 billion annually. BLS estimates that 50 percent of all working time lost to industrial illness is due to dermatitis. Just one case of occupational dermatitis can cost an employer approximately $3,500 in workers' compensation claims and an average disability of 23.9 days, according to the Journal of the American Medical Association.

It is easier to prevent dermatitis than to cure it. There are preventative steps employers and employees can take to care for their hands and prevent occupational dermatitis.

S.T.O.P. Occupational Skin Disorders

Any effort to prevent work-related health issues, including skin disorders, should follow the STOP principle.

S–Substitution:

First and foremost, it is important to replace hazardous workplace substances that may irritate the skin or cause dermatitis with more skin-friendly substances.

T–Technology:

Implement technical measures that reduce skin contact with irritants, such as capsuling machinery, which prevents splashes on the skin.

O–Organization:

Introduce changes in the work flow to limit an employee’s exposure to skin irritants. This can be achieved by rotating personnel more frequently and allowing more drying time before parts need to be touched.

P–PPE:

Use Personal Protective Equipment, such as gloves, to reduce skin contact with irritants.

Help Beyond Hand Washing

Hand washing alone is not enough. To keep hands strong and healthy, employees should use protect and restore creams before and after working. When employees do not use skin creams, physical contaminants and micro-organisms can enter the skin, causing damage and infection. The skin’s natural lipids and moisturizers are also worn away, causing the skin to become dry.

Implementing skin care best practices is essential to maintain healthy skin and reduce the risk of occupational skin disease. It's important to identify the risks employees face and ensure they follow safe working policies, including wearing the recommended PPE. Encourage employees to use the skin care products provided to reduce the risk of skin diseases, such as dermatitis and skin cancer.

Adopting good skin care practice is a critical activity for any organization. It should embrace two distinct aspects:

- Protect. The use of protect cream provides a protective layer, helping to prevent physical contaminants and micro-organisms from entering the skin. The cream helps to maintain the natural condition of the skin, retaining natural lipids and moisture, while working. The protective layer also protects skin against dermatitis and from exposure to UV rays or cold working conditions. It also makes the skin easier to clean with less-aggressive cleansers. Employees should apply protect cream before they start each work period and reapply after washing their hands, or at least every three hours.

- Restore. Restore creams improve skin strength by moisturizing, nourishing, and conditioning the skin, preventing it from becoming dry or damaged, which can eventually lead to occupational skin disease. Restore cream should be applied after working, either at the end of a shift or before a long break from working, such as a lunch break. Workers should apply restore cream at least once daily.

OSDs are an invisible threat that affects an organization's efficiency and the health and well-being of its employees. Keeping employees’ skin in good condition while they work is vital to a business’ success.

Selecting the Appropriate Creams

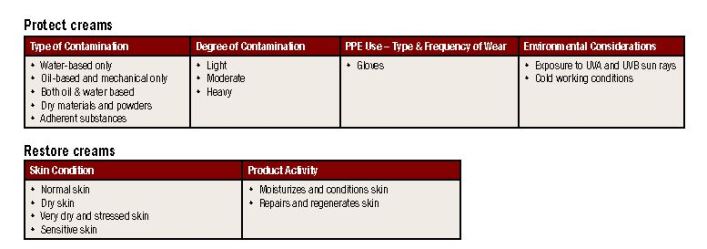

Below is a list of factors that managers should consider when selecting protect and restore creams to keep employees' hands safe and healthy.

Preference factors for protect creams:

- Perfumed or perfume-free

- Silicone-free

- Suitable for use on hands, body, face/Suitable for use on hands and body

- Suitable for allergy sufferers

Preference factors for restore creams:

- Perfumed or perfume-free

- Silicone-free

- Suitable for use on hands, body, and face

- Suitable for use on hands and body

- Suitable for allergy sufferers

The appropriate products should be available and accessible to workers where and when they are required. Creams should be located in key areas such as changing rooms, work area entrances, washrooms, and hand washing stations.

According to the National Institute for Occupational Safety and Health, 13 million workers in the United States are potentially exposed to chemicals that can be absorbed through the skin. If unreported, occupational skin disease in the workplace can cause increased absences among employees and reduced efficiency at work.

Employers are at risk for increased costs due to employee sick days and reduced productivity. To keep teams healthy and productive, health and safety managers should implement skin care best practices in the workplace to reduce the risk of occupational skin disease. The routine use of protect and restore skin creams is essential to keeping employees’ skin healthy.

This article originally appeared in the February 2016 issue of Occupational Health & Safety.