Flashlights: Critical Safety Tools

When conducting safety training, don’t forget what could be the most important tool of all. New technology innovations are yielding important safety benefits.

- By Dawn Dalldorf-Jackson

- Dec 01, 2013

Safety managers give much thought to equipping and training employees for emergency situations and keeping them safe on the job. But when it comes to one critical safety tool -- flashlights -- these same safety professionals may be overlooking the many recent technology innovations and options that are now available to them. By taking the time to understand recent enhancements in flashlight technology, safety personnel can better prepare workers to respond to emergencies and, in general, help maintain a safer working environment.

Following is a primer on what safety professionals should know about the latest in flashlights:

Enhancements in LED Technology

There are times when safety depends on a high-quality flashlight or lantern that delivers extreme brightness, such as when lighting up an accident or fire scene, working in a hazardous environment (such as a refinery), or making repairs under low light or other challenging conditions.

While high lumen flashlight models have been available to industrial and other professionals for several years, the earliest of these lights typically had short run times. They also generated a lot of heat, which made them uncomfortable to hold for long periods of time.

In recent years, LED technology has evolved to a point where flashlight manufacturers now can provide higher lumens while also delivering optimal levels of run time and candela peak beam intensity, a measurement of the brightest spot in a focused beam. These powerful LEDs emit an output in the 500-800 lumens range. They are designed to flood an area with light, making them ideal for lighting incident and accident scenes, as well as large work areas. Similar in light output to many lanterns, many are still small enough to fit into a pocket or on a belt clip. And they do not overheat as previous models did.

For applications that require down-range lighting, workers also need lights that feature a more focused beam. Examples of these activities include search and rescue operations and troubleshooting overhead repairs from the ground. These types of high-performance lights deliver standard lumens but offer much higher levels of candela for operations that require a far-reaching beam. Slightly larger in size than standard LED lights, they also provide generous run times.

Traditional LED hand-held lights continue to evolve, as well. Today’s standard lights offer improved lumen output, typically in the range of 150-350; optimal candela levels; and the longest regulated run times available, allowing for longer periods between recharging or replacing batteries. Traditional LED lights offer the best overall value, which is a real consideration when purchasing multiple lights for a fleet, department, or entire facility. Those that use rechargeable nickel cadmium, lead acid, nickel metal hydride, or lithium ion batteries also feature extraordinarily low operating costs.

Using Flashlights Safely

Certain work environments are extremely dangerous places for flashlights because they can serve as a source of ignition in the presence of flammable gas and liquids and other substances. Because the most hazardous conditions are often in dark places, many manufacturers offer a complete line of Division I safety-rated lights for use when an explosive atmosphere is likely to exist under normal operating conditions. Examples would be working inside an oil or gasoline tank or in certain confined spaces.

Some lights now have safety rating approval based on the requirements of the ANSI/UL 913 and CAN/CSA C22.2 NO 157-97 Intrinsic Safety standards from Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) or from agencies such as SGS/USTC. These intrinsic safety standards for electrical and electronic equipment used in Division 1 hazardous locations hold products to the most stringent requirements.

Manufacturers are now making newer lights with durable thermoplastic material that has anti-static properties, as well as superior resistance to chemicals and solvents used in many industries. In addition, the latest models offer safety features such as a mechanical locking mechanism that requires a tool to open the battery compartment. This helps to prevent batteries from being changed out or the housing from inadvertently being opened in a hazardous environment.

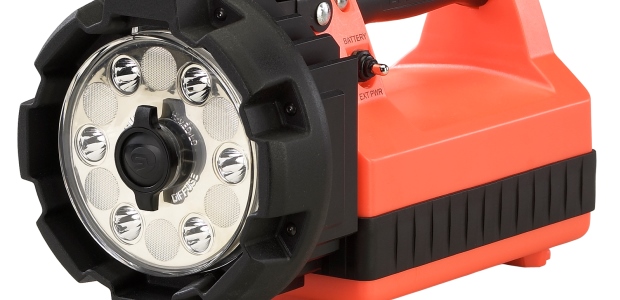

Lanterns That Go the Distance

Lantern products also are becoming available with high lumen technology. These lanterns feature powerful, sweeping beams of light for general scene lighting, large work environments, emergency response scenes, or search and rescue operations. Lanterns also are available with "smart" power failure circuitry, which automatically illuminates the light when the power goes off and can quickly and easily detach from charging stations when power failures occur.

Headlamps, too, have greatly evolved in terms of performance, design, and safety features. Leveraging the latest technology innovations, new models address hands-free lighting needs and offer helpful features for long-range distance lighting, close-up work, and a broad range of everyday uses. Several varieties also enhance job safety with ratings that meet the stringent requirements of Division 1 hazardous locations, while others incorporate high lumen technology.

Training and Inspection

Once portable lights are procured, it is critical to train personnel on the features of them. If lanterns or other flashlight equipment are stored for emergencies, employees must be familiar with their location and how they operate; this information should be reinforced through regular training. It is helpful to post signs to identify power failure lighting units and the location of other emergency lighting.

Routine inspection and testing of emergency and other flashlight equipment is critical. Portable flashlights should be an integral part of your facility's scheduled preventative maintenance program.

Conclusion

The pace of flashlight technology continues to quicken. The wise training manager will stay abreast of technical innovations and ensure employees are equipped with and well trained on the latest high-performance flashlights, lanterns, and headlamps. Offering a wide array of features and benefits, these innovative new models are indispensable tools for keeping professionals safe in the workplace.

This article originally appeared in the December 2013 issue of Occupational Health & Safety.