Major Changes in the OSHA HazCom Standard

Considerable testing of chemicals that are handled in the workplace may be required. This could include flash point, reactivity, or corrosivity.

- By Steven J. Luzik, Richard W. Prugh

- Sep 01, 2012

As stated in the OSHA Fact Sheet entitled "Hazard Communication Standard Final Rule," new changes to OSHA's Hazard Communication Standard (HCS) are bringing the United States into alignment with the Globally Harmonized System of Classification and Labeling of Chemicals, or GHS, and further improving safety and health protections for America's workers.

HCS 2012 still requires chemical manufacturers and importers to evaluate the chemicals they produce or import and to provide hazard information to employers and workers by putting labels on containers and preparing safety data sheets. The old standard allowed chemical manufacturers and importers to convey hazard information on labels and Material Safety Data Sheets in whatever format they chose. The modified HCS provides a single set of harmonized criteria for classifying chemicals according to their health and physical hazards and specifies hazard communication elements for labeling and safety data sheets.

OSHA published a Notice of Proposed Rulemaking to update the Hazard Communication Standard in September 2009 and held public hearings in March 2010. Then, on March 20, 2012, a revised HazCom rule was filed at the Office of the Federal Register, and this rule took effect on May 25, 2012.

The Revised Standard

A statement on the OSHA website advises that "The Hazard Communication Standard (HCS) is now aligned with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). This update to the Hazard Communication Standard (HCS) will provide a common and coherent approach to classifying chemicals and communicating hazard information on labels and safety data sheets. Once implemented, the revised standard will improve the quality and consistency of hazard information in the workplace, making it safer for workers by providing easily understandable information on appropriate handling and safe use of hazardous chemicals. This update will also help reduce trade barriers and result in productivity improvements for American businesses that regularly handle, store, and use hazardous chemicals while providing cost savings for American businesses that periodically update safety data sheets and labels for chemicals covered under the hazard communication standard."

Essentially, there are three major changes to the previous version of the HCS standard. These include:

- Hazard classification: The new mandatory Appendices A, B, C, and D greatly expand the previous Appendices A and B.

- Labels: Chemical manufacturers and importers will now be required to provide a label that includes a harmonized signal word, a pictogram, and a hazard statement for each hazard class and category.

- Safety Data Sheets: MSDSs will now be referred to as SDSs and will now have a specified 16-element format, including 11 elements that will be enforced by OSHA.

- Information and training: To facilitate understanding of the new system, the new standard requires that workers be trained on the new label elements and safety data sheet format.

Implementation Dates

The following dates for implementation of the HCS are given in paragraph (j) of the standard:

- (j)(1) Employers shall train employees regarding the new label elements and safety data sheets format by Dec. 1, 2013.

- (j)(2) Chemical manufacturers, importers, distributors, and employers shall be in compliance with all modified provisions of this section no later than June 1, 2015.

- (j)(2)(i) After Dec. 1, 2015, the distributor shall not ship containers labeled by the chemical manufacturer or importer unless the label has been modified to comply with paragraph (f)(1) of this section.

- (j)(2) (ii) All employers shall, as necessary, update any alternative workplace labeling used under paragraph (f)(6) of this section, update the hazard communication program required by paragraph (h)(1), and provide any additional employee training in accordance with paragraph (h)(3) for newly identified physical or health hazards no later than June 1, 2016.

- (j)(3) Chemical manufacturers, importers, distributors, and employers may comply with either 1910.1200, revised as of Oct. 1, 2011, or the current version of this standard or both during the transition period.

Hazard Classification

As can be seen in the following outlines to the appendices to the HCS, a very large amount of information is required by the Globally Harmonized System for hazards communication and is now required by OSHA.

Health Hazards Criteria (Mandatory Appendix A of 29 CFR 1910.1200)

The following sections provide detailed descriptions of hazards and quantitative criteria for health hazards:

Section/Title

A.0/General Classification Considerations A.1/Acute Toxicity

A.2/Skin Corrosion/Irritation

A.3/Serious Eye Damage/Irritation

A.4/Respiratory or Skin Sensitization

A.5/Germ Cell Mutagenicity

A.6/Carcinogenicity

A.7/Reproductive Toxicity

A.8/Specific Target Organ Acute Toxicity

A.9/Specific Target Organ Chronic Toxicity

A.10/Aspiration Hazards

Although paragraph A.0.2.1 states, "There is no requirement for testing chemicals," it is very likely that quantitative data may not be available to determine whether or not a particular chemical would meet the criteria for a "hazardous material." Thus, it is also very likely that some type of testing would beequired for chemicals that are handled in the workplace to determine the extent of –- or absence of –- hazard, particularly for the training of employees.

Physical Hazards Criteria (Mandatory Appendix B of 29 CFR 1910.1200)

The following sections provide detailed descriptions of hazards and quantitative criteria for physical hazards:

Section/Title

B.1/Explosives

B.2/Flammable Gases

B.3/Flammable Aerosols

B.4/Oxidizing Gases

B.5/Gases Under Pressure

B.6/Flammable Liquids

B.7/Flammable Solids

B.8/Self-Reactive Chemicals

B.9/Pyrophoric Liquids

B.10/Pyrophoric Solids

B.11/Self-Heating Chemicals

B.12/Water-Reactive Materials

B.13/Oxidizing Liquids

B.14/Oxidizing Solids

B.15/Organic Peroxides

B.16/Corrosive to Metals

If there is any likelihood that a chemical could be described as being within one or more of the above categories, considerable testing may be required. This could include flash point, heat of combustion, heat of decomposition, burning rate, thermal stability, reactivity, and/or corrosivity.

Allocation of Label Elements (Mandatory Appendix C of 29 CFR 1910.1200)

The following sections provide detailed descriptions of the requirement for the labeling of materials that present one or more of the hazards described in Appendices A and/or B in the OSHA standard:

Section/Title

C.1/Supplier's Information

C.2/Labeling Requirements

C.2.1/Signal Word

C.2.2/Hazard Statement

C.2.3/Pictogram Requirement

C.2.4/Precautionary Statement

C.3/Supplementary Hazard Information

C.4/Specifications for Warnings

C.4.1 to C.4.13/Specific Requirements for Health Hazards

C.4.14 to C.4.30/Specific Requirements for Physical Hazards

For each of the hazards in Sections C.4.1 to C.4.30, a Hazard Category, a Signal Word, and a Hazard Statement are suggested, together with the required Pictogram. Also, Precautionary Statements are suggested for Prevention of injury, Response to exposure, Storage requirements, and Disposal methods.

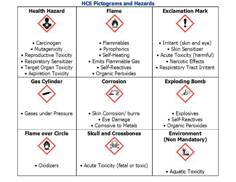

The following pictograms must be used if the material is hazardous to health or if it presents a physical hazard:

HCS Pictograms and Hazards

Health Hazard

Carcinogen

Mutagenicity

Reproductive Toxicity

Respiratory Sensitizer

Target Organ Toxicity

Aspiration Toxicity

Flame

Flame

Flammables

Pyrophorics

Self-Heating

Emits Flammable Gas

Self-Reactives

Organic Peroxides

Exclamation Mark

Irritant (skin and eye)

Skin Sensitizer

Acute Toxicity (harmful)

Narcotic Effects

Respiratory Tract Irritant

Gas Cylinder

Gases under Pressure

Corrosion

Skin Corrosion/Burns

Eye Damage

Corrosive to Metals

Exploding Bomb

Explosives

Self-Reactives

Organic Peroxides

Flame over Circle

Oxidizers

Skull and Crossbones

Acute Toxicity (fatal or toxic)

Environment (Non Mandatory)

Aquatic Toxicity

Safety Data Sheets (Mandatory Appendix D of 29 CFR 1910.1200)

In the past, the requirements for quantitative data in MSDSs have been limited to vapor pressure, flash point, and threshold limit value for inhalation toxicity. However, the revised HCS requires much more quantitative data in SDSs (note that the word "Material" is removed from the title of these documents). The outline below presents the data that are now required (with the exception that OSHA would not require the "Non-mandatory" data):

Table D.1—Minimum Information for an SDS

Heading, Subheading

1. Identification. Product identifier; Restrictions on use; Name, address, and telephone number of the chemical manufacturer, importer, or other responsible party; Emergency phone number.

2. Hazard(s) identification. Chemical classification; Signal word; hazard statement(s); Pictograph symbol(s); Precautionary statement(s).

3. Composition/information on ingredients. Chemical name; CAS number; Chemical name and concentration of all ingredients which are classified as health hazards.

4. First-aid measures. Description of necessary first-aid treatments, according to the different routes of exposure, i.e., inhalation, skin and eye contact, and ingestion; Symptoms/effects, acute and delayed.

5. Fire-fighting measures. Suitable (and unsuitable) extinguishing media; Special protective equipment and precautions for fire-fighters.

6. Accidental release measures. Personal precautions, protective equipment, and emergency procedures; Methods and materials for containment/cleanup.

7. Handling and storage. Precautions for safe handling and storage conditions.

8. Exposure controls/personal protection. OSHA permissible exposure limit; ACGIH Threshold Limit Value; Appropriate engineering controls; Individual personal protective equipment.

9. Physical and chemical properties. Appearance; Odor threshold; pH; Melting point; Boiling point; Flash point; Evaporation rate; Flammability and Limits; Vapor pressure; Vapor density; Solubility; Partition Coefficient; Autoignition temperature; Viscosity.

10. Stability and reactivity. Reactivity; Chemical stability; Decomposition temperature; Hazardous decomposition products; Reactions; Incompatibility.

11. Toxicological information. Toxicological effects; Likely routes of exposure; Symptoms of exposure; Delayed effects of exposure; Carcinogen listing

12. Ecological information. (Non-mandatory) Ecotoxicity (aquatic and terrestrial); Persistence; Mobility; Bioaccumulative potential; Ozone destruction.

13. Disposal considerations. (Non-mandatory) Safe handling of wastes; Methods of disposal, including contaminated packaging.

14. Transport information. (Non-mandatory) UN number; UN shipping name; Transport class; Packing group; Other transport precautions.

15. Regulatory information. (Non-mandatory) Safety, health and environmental regulations specific for the product in question; except mandatory if covered by 29 CFR 1910.1000 to 29 CFR 1910.1096.

16. Other information. Date of preparation or revision of the SDS.

A statement that has appeared in previous MSDS requirements has been retained in the updated HCS, namely: "If no relevant information is found for any given subheading within a section, the SDS shall clearly indicate that no applicable information is available." Such statements –- and "Stable at normal temperatures and pressures" -– show an absence of information that may be critically important in the control of hazards and should be avoided. In particular, training of employees in chemical hazards requires that most of the information specified in the above table be obtained and documented.

Diligent research into the wide expanse of the open literature would be needed to ensure that "no applicable information is available," to avoid the situation where OSHA would find that pertinent hazards information indeed was available.

Guidelines for Employer Compliance (Advisory Appendix E of 29 CFR 1910.1200)

Appendix E has not been modified in the new HCS and is included verbatim in the current standard. However, it is likely that "Material Safety Data Sheet" would be replaced by "Safety Data Sheet" and "MSDS" would be replaced by "SDS." The sections of this appendix are:

Section/Title

1/Become Familiar with the Rule

2/Identify Responsible Staff

3/Identify Hazardous Chemicals

4/Preparing/Implementing Program

4A/Labels/Other Forms of Warning

4B/Material Safety Data Sheets

4C/Employee Information and Training

4D/Other Requirements

5/Checklist for HCS Compliance

6/Further Assistance [202-219-8151]

Guidance for Carcinogenicity Hazard Classification (Non-Mandatory Appendix E)

The mandatory criteria for classification of a chemical for carcinogenicity under HCS are found in Appendix A.6 to this section. This non-mandatory appendix provides additional guidance on hazard classification for carcinogenicity. The sections of this appendix are:

Section/Title

A/Background Guidance: Humans; Animals

B/International Agency for Research on Cancer Classifications

C/National Toxicology Program Classifications

D/ Equivalence Among Classifications

Conclusion

OSHA has taken a major step in adopting GHS for the U.S. HazCom Standard. Considerable effort will likely be required to obtain the chemical hazards data and information that will be needed for SDSs and for additional employee training.

It will be important for members of management and technical staffs at plants and other facilities that handle hazardous materials to become familiar with the new HCS. Several pertinent documents are readily available at http://www.osha.gov/hazcom/index.html.

This article originally appeared in the September 2012 issue of Occupational Health & Safety.

About the Authors

Steven J. Luzik, P.E., CFEI is a Senior Process Safety Specialist at Chilworth with more than 30 years' experience in the area of fire and explosion hazards, including gas/vapor explosions, dust explosions, and fire and explosion protection strategies. He is a Certified Fire and Explosion Investigator (CFEI) with the National Association of Fire Investigators, a member of the American Society for Testing and Materials (ASTM) E-27 Committee on Hazardous Properties of Chemicals, the National Association of Fire Investigators, and the National fire Protection Association. He has written numerous publications in the areas of fire and explosion prevention, protection, and investigation. As the world's leading one-stop source for industry's process safety and optimization needs, the Chilworth Global has international consulting bases and laboratory testing facilities with state-of-the-art dust explosion and electrostatic laboratories and a specialist laboratory for the evaluation of thermal runaway reactions.

Richard W. Prugh, M.S.Ch.E., CSP, P.E., is a Senior Process Safety Specialist at Chilworth who provides process safety engineering expertise focused on chemical manufacturing and oil/gas operations. He has extensive experience in instrument engineering, explosion hazards testing, explosives manufacturing and testing, pilot-plant supervision, organic chemicals research, safety and fire protection audits, and process safety consulting. Since 1985, he has provided process safety services to chemical and petrochemical plants in throughout the United States and internationally. He has presented at the Loss Prevention Symposia more than 25 times and is the author of the Toxicity section of the 2008 issue of "Perry's Chemical Engineers' Handbook." As the world's leading one-stop source for industry's process safety and optimization needs, the Chilworth Global has international consulting bases and laboratory testing facilities with state-of-the-art dust explosion and electrostatic laboratories and a specialist laboratory for the evaluation of thermal runaway reactions.