Unplanned Shutdowns as Proof Test Credits: What to Know and Steps to Take

Unplanned shutdowns can provide partial proof test credits for Safety Instrumented Functions (SIFs), helping optimize maintenance schedules while ensuring safety compliance.

- By Chris Powell

- Dec 04, 2024

Safety Instrumented Functions (SIFs) must undergo regular proof testing at specific intervals to ensure they perform as expected during potentially hazardous events.

An unplanned shutdown can serve as an opportunity to confirm the functionality of these safety systems and potentially extend the time before the next scheduled proof test. But first, it’s necessary to have clear guidance on how to leverage proof test credit during an unplanned shutdown, maintaining safety while optimizing your maintenance schedule.

The Importance of Proof Tests

SIFs are required to undergo proof tests at specific intervals, measured in months or years, to validate their probability of failure on demand (PFD). These tests are crucial for detecting dangerous covert failures that could render a safety instrumented function (SIF) inoperable during a potentially hazardous event. Proof tests are given a specified amount of coverage, expressed as a percentage of dangerous failures detected versus total failures (both detected and undetected).

The concept of taking credit for an unplanned shutdown hinges on the idea that these events can provide partial proof that the SIF will perform as required, even if the full scheduled test is delayed.

Proof Test Credits During Unplanned Shutdowns

A proof test credit is a recognition given when an unplanned shutdown or unexpected process event effectively tests a SIF. Instead of waiting for the scheduled proof test, the event itself serves as an indication that the safety systems function, at least partially, as intended.

The recognition for a proof test credit is typically given by the plant’s safety or engineering team, often in collaboration with management and sometimes with input from industry experts. This team reviews the documentation and analysis of the unplanned shutdown to determine if the event meets the criteria for taking proof test credit.

If they conclude that the event effectively tested the SIF and provides sufficient evidence of its reliability, they can credit the process trip to extend the interval before the next scheduled proof test. This ensures that the system continues to meet safety requirements without unnecessary downtime.

Determining the amount of proof test credit that can be taken requires careful consideration. Crediting the equivalent of a full stroke proof test is not recommended for an unplanned shutdown. In Safety Integrity Level (SIL) calculations for valves, varying amounts of credit are given based on the robustness of the test. For instance:

- A full stroke proof test, particularly if a leak test is included, might offer 90 percent proof test coverage.

- A partial stroke test, which only moves the valve a minimal amount, might offer 60 percent coverage.

The amount of credit possible from an unplanned trip will likely fall somewhere between these values, depending on what portion of failures could be detected.

What Happens During an Unplanned Shutdown?

Unplanned shutdowns can be triggered by a variety of factors, including equipment failure, process upsets, safety concerns, or external events such as power outages. During an unplanned shutdown, the plant’s Safety Instrumented Functions (SIFs) are automatically activated to bring the plant into a safe state as quickly as possible. Here’s what typically happens:

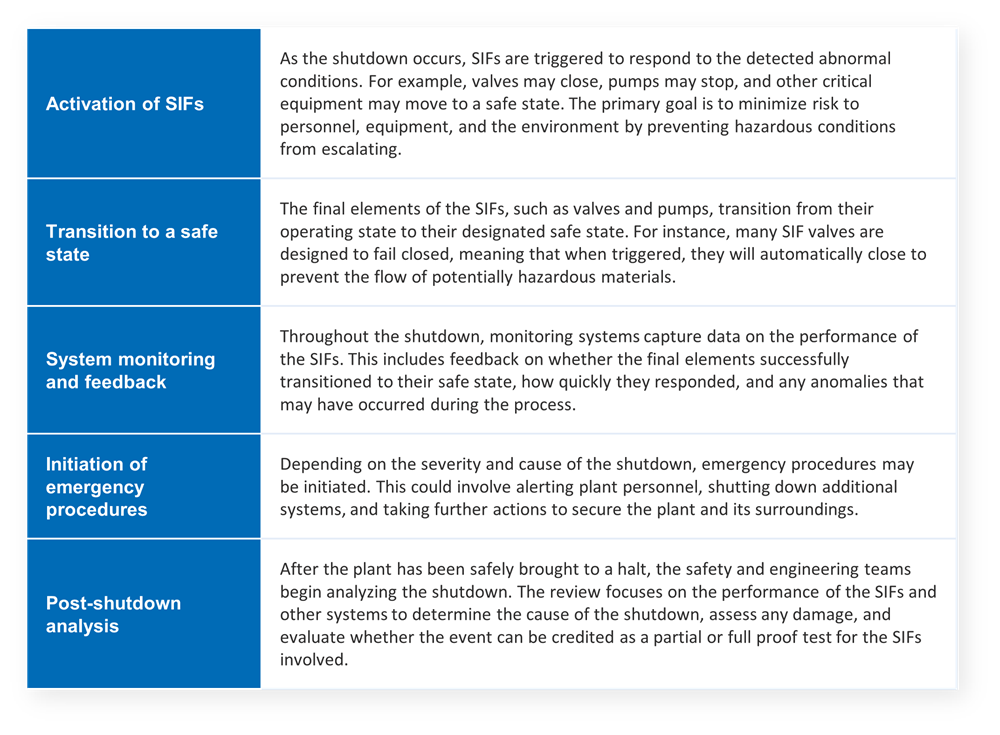

Table 1: What happens during an unplanned shutdown?

The effectiveness of the SIFs during an unplanned shutdown is critical, as their ability to bring the plant to a safe state without incident is what prevents the situation from becoming a serious hazard. This performance is also what allows operators to consider taking proof test credit, as the event provides real-world validation of the SIFs' functionality.

Establishing Proof Test Credits During Unplanned Shutdowns

To ensure a smooth and effective process for requesting proof test credits, it's essential to follow the five steps below. Each step is designed to capture the necessary data, analyze the event thoroughly and secure approval for any adjustments to your proof test schedule.

1. Document the Event Thoroughly

As soon as an unplanned shutdown occurs, document all relevant details, including the date, time and conditions. Identify which SIF components were involved and gather data on process conditions, system responses and any alarms that were triggered.

2. Assess Which Devices Can Be Credited

Determine which sensors, logic solvers and final elements were involved in the shutdown. Key questions to answer include:

- What caused the trip? Was it the SIF sensor or something else?

- How was the trip commanded by the logic solver?

- What moved or stopped moving in the final elements?

Typically, SIF sensors will not be involved during an unplanned shutdown unless a process excursion caused the event. Final elements like valves, on the other hand, can usually be credited if they transitioned to their safe state.

3. Analyze and Compare

Compare the unplanned shutdown conditions with your standard proof test procedures. Determine how much of the proof test was covered and which aspects were not. For example, while a valve may have closed, did it fully seat and prevent leakage? This analysis will help in the evaluation for how much credit can be taken.

4. Prepare and Submit Your Request

Compile your findings into a detailed report, outlining the extent of the testing that occurred during the unplanned shutdown. Submit this report to your plant management or safety committee for review. This team will evaluate whether the event justifies taking proof test credit and delaying the next scheduled test.