Six Simple Ways to Protect Workers From Electrical Shock

- By Devin Partida

- Sep 16, 2021

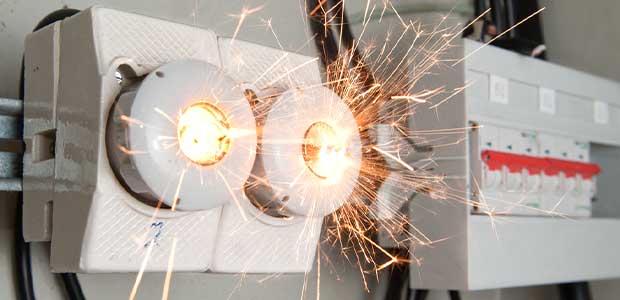

Electrical shock hazards are a relevant threat in many workplaces, causing 166 worker deaths in 2019. With electrical equipment being a common sight in any workplace, preventing these accidents is crucial. Not everyone works with high-voltage equipment, but electrical hazards are more common than some might realize. Here are six ways employers can protect their workers from electric shock.

1. Use Well-Insulated Cables

Workplaces can significantly reduce the risk of electrical hazards by using the right kind of cables. When installing or rearranging equipment, businesses should ensure they are using lines with thick, resilient insulation.

The wires that equipment comes with may not feature sufficient insulation. After years of use, some cables’ insulation may wear out or break. For example, businesses that move items around regularly should periodically change out lines for new, well-insulated ones.

2. Protect Cables With Conduits

Some work environments may need additional protection for their electrical cables. Any job site located outdoors or with many wires should run them through protective conduits to keep them organized and safe from hazards. These solutions are relatively inexpensive but can provide significant protection.

Some conduits can withstand temperatures between -58 and 392 F, ideal for outdoor workplaces, like construction sites. Indoor areas may not need that level of protection, but conduits can still keep cables in one place, safe from crushing or pinching.

3. Avoid Working Near Electric Lines When Possible

Construction or building maintenance crews may have to work near utility lines, which can deliver substantial shocks. If teams are digging or working off the ground, these cables pose a significant threat. To minimize their risk, workers should know where electrical lines are and avoid them as much as possible.

A few days before starting a project, teams can call 811 to request that they mark buried utility lines’ approximate location. When working, they should give these spots as much distance as their work will allow.

4. Check for and Report Electrical Hazards

Electric shocks are often the result of some type of failure, like a wiring error or exposed wire. Workers can avoid these hazards by checking for them before working with or near electrical equipment. If anyone notices a danger, they should report it so the appropriate staff can take care of the issue.

Some workplaces use sensors to alert management of potential hazards. Companies with a sufficient budget should consider this tech-centric approach to hazard reporting, as it may be more reliable than potentially forgetful or distracted employees.

5. Wear PPE Rated for an Appropriate Voltage

Any employee who works with or near wires should wear shock-resistant PPE. That includes rubber gloves, insulated clothing and protective eyewear. Remember that this PPE is rated for a specific voltage, so workers should have the correct items for what they work with.

Just as workers check for electrical hazards, they should also inspect their PPE before working. Any tears or spots where insulation has worn thin could jeopardize their safety.

6. Train Employees on Electrical Safety

No matter what other steps an employer takes, they cannot overlook the importance of thorough training. Employee errors can introduce risks despite any amount of safety protocols. As such, it is critical to teach all workers about electrical threats and how to spot and prevent them. If anyone regularly works with high-voltage equipment, they may need periodic refreshers. These training sessions will help prevent potentially dangerous errors, keeping workers as safe as possible.

Electrical Shocks Are Dangerous but Preventable

Electrical hazards are present in many workplaces and can be dangerous, even fatal. Despite how grave these risks are, they are often entirely preventable. If workplaces follow these steps, they can keep their employees safe no matter what electrical hazards they face.