OSHA's Crystalline Silica Standards: New Solution to a Very Old Problem

Virtually all portions and requirements of OSHA's Crystalline Silica Standards are now in effect and enforceable, so immediate compliance is imperative.

- By T. A. Rowland III

- Jun 01, 2019

It was March of 1930. Mohandas Gandhi was in the midst of his Salt March to the Arabian Sea, the industrialized world was about to experience the lowest point of the Great Depression, Babe Ruth had signed a new contract with the New York Yankees, and ground was being broken in West Virginia on construction of a diversion channel known as the Hawk's Nest Tunnel.

The tunnel was to be a critical component of a hydroelectric plant, but before the three-mile tunnel through Gauley Mountain was completed, at least 764 laborers died from acute silicosis (United States National Park Service, https://www.nps.gov/neri/planyourvisit/the-hawks-nest-tunnel-disaster-summersville-wv.htm). As hundreds of unprotected workers picked, dug, and blasted their way through the silica-rich rock, a cloud of choking dust enveloped the tunnel and permeated the workers' lungs. Eight decades later, the Hawk's Nest Tunnel incident is still recognized as one of the worst occupational disasters in modern history.

In 1936, a congressional subcommittee published its findings regarding the Hawk's Nest incident. While the report included a strong indictment of the builders of the tunnel, no further actions were undertaken. Fortunately, publicity regarding the incident did shape opinions, and by the close of 1937, all but two of the then 48 states had enacted laws benefiting workers with silicosis. While these measures constituted steps in the right direction, they were not preventative in nature. Such critical employer requirements would not be enacted for another 80 years.

New Solution

In 1997, the World Health Organization's International Agency for Research on Cancer (IARC) classified Crystalline Silica dust as a human carcinogen (Group 1). Ultimately, this act placed the IARC in agreement with the U.S. National Toxicology Program and the National Institute for Occupational Safety and Health that occupational exposure to silica increases one's odds of developing lung cancer. This meant that silica was a human carcinogen present at countless workplaces and whose occupational exposure limit had not been re-evaluated in nearly half a century. It was finally time for significant regulatory change.

In March 2016, the Occupational Safety and Health Administration (OSHA) issued a new rule to control exposure to respirable crystalline silica. The silica rule is comprised of two separate standards. The first (29 CFR 1926.1153) is known as the Silica Construction Standard, and it applies to work within the construction industry, including construction, demolition, alterations, repair, bridge erection, roadwork, excavations, large-scale painting projects, etc. The second (29 CFR 1910.1053), known as the General Industry & Maritime Standard, applies to work within the manufacturing (static in nature) and shipyard industries. The table below provides a summary of the nature and requirements of the rule.

OSHA estimates that 2,300,000 workers in the United States are routinely exposed to respirable crystalline silica, the vast majority of whom are in the construction industry. Of these, OSHA estimates that more than 640,000 are being exposed to concentrations that exceed the PEL. When compared to other regulated hazardous substances, crystalline silica has an alarming percent of positive exposure assessments.

Do Our Employees Fall Under the Crystalline Silica Standards?

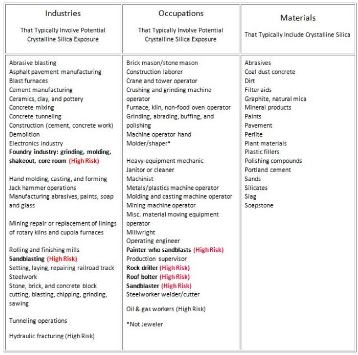

The table below provides information regarding industries and occupations that likely fall under the standard.

What Should You Do to Protect Your Workers and Insurance Compliance?

Virtually all portions and requirements of OSHA's Crystalline Silica Standards are now in effect and enforceable, so immediate compliance is imperative. In order to achieve this state, employers should consider engaging the services of a Certified Industrial Hygienist (CIH) with pertinent training and experience. Employers and their consulting industrial hygienists must ensure that workers are properly protected and that employers are in full compliance. As a minimum, the consulting industrial hygienists should provide employers with the following critical services:

1. Training for personnel involved in silica work, including instruction regarding the OSHA Standard and Respiratory Fit Testing;

2. Development of task-specific Written Exposure Control Plans, including assistance with implementation of the plan;

3. Collection of occupational exposure air samples to determine the concentration of silica to which workers may be exposed;

4. General client consultations regarding:

a) Compliance with the silica standards,

b) Proper control methods,

c) Designation of a competent person,

d) Personal protective equipment,

e) Interpretation of sampling data,

f) Proper housekeeping practices,

g) Medical surveillance programs,

h) Recordkeeping requirements.

To find a CIH to assist you and your company, visit the American Industrial Hygiene Association website at https://www.aiha.org/about-ih/Pages/Find-an-Industrial-Hygienist.aspx.

This article originally appeared in the June 2019 issue of Occupational Health & Safety.