NTSB Sets Meeting on San Francisco International Near Miss

Air Canada flight 759, an Airbus A320, was cleared to land on runway 28R at San Francisco International on July 7, 2017, but the airplane instead lined up with parallel taxiway C, which had four airplanes on it awaiting takeoff clearance. Air Canada flight 759 descended to about 60 feet above the ground, and the crew then initiated a go-around after overflying the first airplane on taxiway C.

The National Transportation Safety Board will hold a board meeting Sept. 25 to determine the probable cause of a July 7, 2017, near miss at San Francisco International Airport.

Air Canada flight 759, an Airbus A320, was cleared to land on runway 28R at San Francisco International, but the airplane instead lined up with parallel taxiway C, which had four airplanes on it awaiting takeoff clearance. Air Canada flight 759 descended to about 60 feet above the ground, and the crew then initiated a go-around after overflying the first airplane on taxiway C.

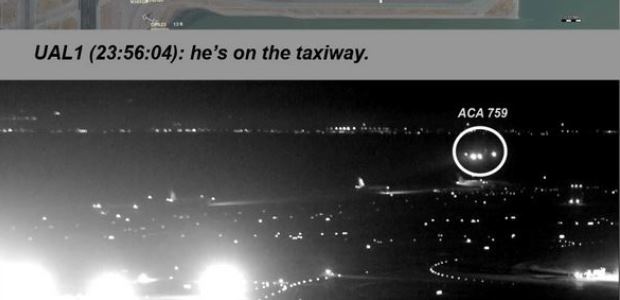

The incident occurred about 11:56 p.m., according to information NTSB previously released about it. The four aircraft awaiting takeoff clearance were United Airlines flight 1, a Boeing 787; Philippine Airlines flight 115, an Airbus A340; United Airlines flight 863, also a Boeing 787; and United Airlines flight 1118, a Boeing 737. The Air Canada flight was inbound from Toronto.

NTSB was notified of the incident on Sunday, July 9, and opened an investigation. The NTSB investigator-in-charge formed these groups: Air Traffic Control, Operational Factors, Human Performance, Airports, and Flight Data Recorders. They reviewed systems in use at the time and interviewed controllers and management personnel at the SFO ATC tower and the Northern California Terminal Radar Approach Control (TRACON), as well as interviews with the Air Canada flight crew and the flight crew of the airplane that landed on runway 28R minutes before the incident. The groups obtained statements from the flight crew members of the aircraft that were holding on taxiway C at time of the incident. Nighttime observations of the airport lighting from the ground and air were also conducted. The groups visited Air Canada in Toronto, where the flight crew was based, to review records and interview company personnel. The incident airplane's cockpit voice recorder had been overwritten, so NTSB investigators did not have its data.

NTSB reported that the airport's runway 28L was closed to accommodate construction as the of the incident, with its approach and runway lights turned off, and a 20.5-foot-wide lighted flashing X (runway closure marker) was placed at the threshold. Construction on runway 28L was part of a project that started on Feb. 21, 2017, and notices to airmen were issued to alert operators of its operational status. The runway and approach lighting for 28R were on and set to default settings, which included a 2,400-foot approach lighting system, a precision approach path indicator, touchdown zone lights (white), runway center line lights (white at the approach end), runway threshold lights (green), and runway edge lights (white at the approach end).

The lights for taxiway C were also on and set to default settings that included center line lights (green) along its length, with edge lights (blue) and center line lights (green) illuminating the transition or stub taxiways from the runway to the taxiway.

The captain was the pilot flying Air Canada aircraft with the first officer monitoring. The captain had more than 20,000 total flight hours, of which about 4,797 hours were as captain in Airbus A320‑series airplanes. The first officer had about 10,000 total flight hours, of which over 2,300 hours were in Airbus A320-series airplanes.

The flight crew of the first airplane waiting on taxiway C transmitted statements regarding the approaching Air Canada aircraft, one of which mentioned that it was aligned with the taxiway while on short final. The flight crew of the second airplane on the taxiway switched on their airplane's landing lights as the incident airplane approached.