A Simplified Method for Determining Residual Risk in RIA TR R15.306-2016

The combination of initial risk and risk reduction measures fixes the residual risk, thus simplifying the determination of residual risk and avoiding errors.

In 2014, the Robotics Industry Association (RIA) published RIA TR R15.306 (Technical Report for Industrial Robots and Robot Systems—Safety Requirements—Task-based Risk Assessment Methodology). The document was updated in 2015, then again in 2016. The risk assessment methodology in this document is an excellent tool for robotic safety risk assessment. Although written specifically for robotics, it can be easily adapted for use for other machine safety hazards.

Using the methodology of TR R15.306-2016, the user:

1. calculates the initial risk of injury due to a potential hazard;

2. selects risk reduction measures; then

3. calculates the residual risk (i.e., the risk remaining after risk reduction measures are taken).

However, while the document does not indicate so explicitly, once initial risk is determined and risk reduction measures are selected, the residual risk is essentially fixed. The purpose of this article is to explain how the combination of initial risk and risk reduction measures fixes the residual risk, thus simplifying the determination of residual risk and avoiding errors.

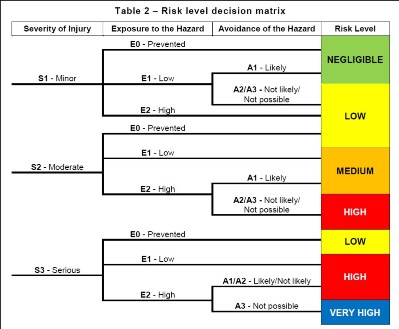

Risk is the combination of the probability of occurrence of harm and the severity of that harm. In TR R15.306-2016, Risk is determined by three criteria:

- Injury Severity is a function of the degree of estimated harm due to each hazard while a person is performing a task. Severity has three ratings: S3 (Serious), S2 (Moderate), and S1 (Minor).

- Exposure is a function of the estimated incidence of exposure (either frequency or duration) to the hazard. Exposure has three ratings: E2 (High), E1 (Low), and E0 (Prevented).

- Avoidance is an assessment of a person’s ability to sense and elude a hazardous situation. Avoidance has three ratings: A3 (Not possible), A2 (Not likely), and A1 (Likely).

The combination of Severity, Exposure, and Avoidance yields the initial Risk Level (see RIA TR R15.306-2016, Table 2).

from RIA TR R15.306-2016

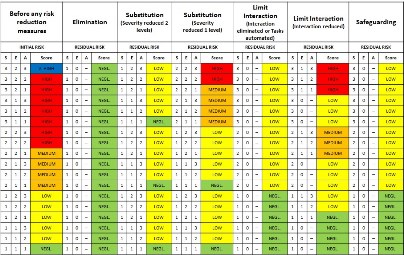

Once the initial risk level is determined, the user selects one or more risk reduction measures. Following the Hierarchy of Risk Reduction Measures (RIA TR R15.306-2016, Table 3), the risk reduction measures are:

- Elimination (i.e., eliminate the hazard)

- Substitution (i.e., substitute the hazard with a lesser hazard)

- Limit Interaction (i.e., reduce or eliminate interaction between the hazard and the person)

- Safeguarding (Safeguards and Safety-Related Parts of the Control System, or SRP/CS)

- Complementary Protective Measures (measures that may reduce the severity of injury, such as emergency stops, enabling devices, and energy isolation

- Information for Use (Warnings and Awareness Means, Administrative Controls, PPE)

Note that according to TR R15.306-2016, neither Complementary Protective Measures nor Information for Use may be used until or unless the risk level is or has been reduced to LOW or NEGLIGIBLE.

The residual risks resulting from the risk reduction measures chosen are as follows:

- If Elimination is used, then all values for Severity, Exposure, and Avoidance are reduced to their lowest rating levels, S1 and E0 (note that once Exposure is eliminated, Avoidance is no longer applicable).

- If Substitution is used, then Severity is reduced, but Exposure and Avoidance remain unchanged. (Note that the 2014 version of TR R15.306 stated the following: "Exposure to a hazard or avoidance of a hazard does not impact the severity of a potential injury.") The level of Severity reduction depends on the substitution, and the substitution must meet the criteria for Substitution shown in TR R15.306-2016. For example, suppose you substitute a concentrated acid (with an initial Severity rating of S3) with a weaker acid. The user need only determine the resulting Severity rating (S2 or S1) of the weaker acid.

- If Limit Interaction is used and human interaction is eliminated, or we automate the tasks or the material handling, then Exposure is reduced to E0 (and, therefore, Avoidance is no longer applicable), but Severity remains unchanged.

- If Limit Interaction is used and human interaction is reduced, then Exposure is reduced one level (as long as it meets the criteria for Exposure), but Severity and Avoidance remain unchanged.

- If Safeguarding is used, then Exposure is reduced to E0 (and, therefore, Avoidance is no longer applicable), but Severity remains unchanged.

- If Complementary Protective Measures or Information for Use is used, then Avoidance is reduced one level (as long as it meets the criteria for Avoidance), but Severity and Exposure remain unchanged.

Graphically, the results of using Elimination, Substitution, Limit Interaction, or Safeguarding are illustrated as follows:

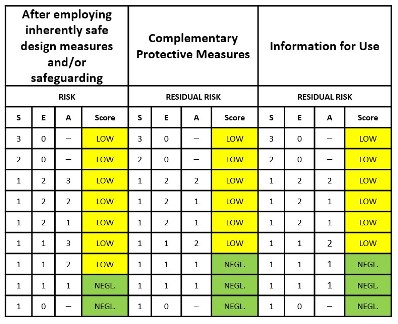

As stated previously, neither Complementary Protective Measures nor Information for Use may be used until or unless the risk level is or has been reduced to LOW or NEGLIGIBLE. The following graphic illustrates the results of using them once the initial risk has been reduced to LOW or NEGLIGIBLE by Elimination, Substitution, or Limit Interaction (known collectively in TR R15.306-2016 as Inherently Safe Design Measures) or Safeguarding:

Note that while the use of Complementary Protective Measures and Information for Use will certainly improve safety, unfortunately, in most instances, the resulting residual risk level will not change from LOW to NEGLIGIBLE. For example, suppose, after employing Safeguarding, the risk is S1, E2, A3 (which is LOW). You then employ Information for Use. The resulting risk is S1, E2, A2, which is still LOW.

This article originally appeared in the July 2018 issue of Occupational Health & Safety.