Facilitator or Steering Team? Leading BBS from Within

The BBS facilitator will need to have a consulting mindset to determine the best approach and a teachable point of view to know what methodologies to leverage.

Through personally implementing hundreds of new processes and executing improvements to just as many efforts led by other experts, experience teaches how BBS is led and structured is different for every company.

Socrates advised, "Prescription before diagnosis is malpractice." Like any change designed to positively improve a culture, the approach should be made to fit the operational and logistics realities and what people will and won’t support. One area of potential malpractice in implementing BBS has to do with predefining who is responsible for overseeing the efforts, from designing through monitoring and continuous improvement. Some say the efforts should be led by someone with a full-time responsibility, while others insist this should be shared by a group such as a steering team or committee. Both have merit and should be explored further.

Facilitators, Sponsor, SPA?

If a company is looking to implement across the company with many different locations and cultures, often a facilitator is leveraged to lead the efforts. This person must have a firm understanding of the range of options and what leads to success and failures. In some very small companies or groups, the full responsibility of BBS may exist with a single person because of resource or logistics limitations. Most often, the role of facilitator is not a full-time responsibility. Typically this individual takes on the responsibility in addition to his or her regular duties, slowly enables a team of individuals to become self-directed, and, over time, backs away from having a hands-on role to allow ownership to exist within the group.

The facilitator will need to have a consulting mindset to determine the best approach and a teachable point of view to know what methodologies to leverage. The facilitator also will need to explain those methodologies to those impacted by the process in a just-in-time manner. Sometimes this person is someone from the safety department, but not if there would be a conflict in current area of focus (i.e., currently focusing on compliance or enforcement) or how the safety professional is currently viewed (think safety police vs. safety coach). Other times, this is a professional development opportunity for an individual or a job for someone who has experience leading complex change.

Rather than assigning someone to make all of the decisions or lead the bulk of the activities, sometimes all that is needed is a sponsor to a group that makes the decisions. This person would be someone from leadership who can speak to other leaders to gain support or provide feedback if it is waning. He or she would also speak with the employee population or bargaining unit representation to gain support and facilitate involvement. This person can act in a role to help the process get up and running or even act as a member of a team with shared responsibilities to make the process successful, while also ensuring continuity with other traditional safety efforts and the overall operational or business strategy. Some companies identify a Single Point of Accountability (SPA) to ensure someone is directly accountable for leading the efforts, coaching for continuous improvement and removing the barriers to success. This allows others to know who specifically can be approached to help with concerns.

Figure:

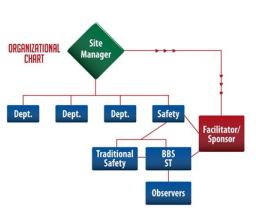

Figure: Sample Common Organizational Structure for BBS Steering Team (ST)

Structuring a Team

The most common approach is to have a team become the designers, communicators, and overseers of the efforts. Where possible, it is preferred to attempt to leverage existing teams as long as the members don’t already have too much on their plate. This team must be viewed as successful with past efforts; be representative of the work areas, levels, and culture; able to meet frequently enough and develop consensus on decisions; and be made up of known influential people. Culture change happens best from within, so the team needs to be structured with those who can successfully lead and influence this change.

Every so often, the team already has the responsibility of leading other safety efforts driven by the safety department that are more traditional in nature (e.g., compliance, enforcement, policy and procedure creation, inspections, audits). Where this is the case, consider developing a new team that will complement the existing safety efforts, rather than taking on everything at once. Resource realities and trust levels typically determine how to structure this and whom to involve.

However you lead the efforts within your company, in summary, remember these principles. Culture change happens best from within. People are more likely to have ownership in something they had a hand in creating. Self-directed efforts are ideal but don't happen on their own; sometimes a facilitator is needed. There should be continuity between BBS and the other safety efforts and between the overall safety and business strategies. External experts should advise but not direct the approach. The approach should be made to fit the site.

If you are unable to modify the structure, terminology focus, or materials, it will eventually become something of value you once did. Consider your organization: How can you best structure this in a way to meet your realities and ensure it delivers sustainable value?

This article originally appeared in the May 2016 issue of Occupational Health & Safety.