Maintaining Body Temperature in Extreme Conditions with FR Garments

By selecting FR garments with THL measures and layering in mind, safety managers can take steps to ensure employees will be able to maintain a safe and comfortable temperature in the workplace.

- By Cortlandt Minnich

- Mar 01, 2015

The ability to regulate body temperature in extreme temperatures can be challenging under even the most normal circumstances. But in situations requiring flame-resistant (FR) garments, the natural insulation properties of FR clothing can create additional obstacles. When developing an FR garment program for hot or cold environments, special considerations must be taken to ensure workers remain as safe and comfortable as possible on the job.

A Metric for Evaluating Garments for use in Hot Environments

Heat stress—which is commonly experienced by workers exposed to extreme heat—can result in heat stroke, heat exhaustion, heat cramps, or heat rashes.1 In fact, the U.S. Bureau of Labor Statistics (BLS) reports that "exposure to environmental heat" caused 177 deaths and 13,580 cases of days away from work in the private sector workforce2 from 2003 to 2008.

While heat stress can be attributed to external factors, such as temperature, workplace uniforms and other factors can contribute to the impact of these sources of heat. A worker may not consciously realize the effect of his or her garments on core body temperature. Just as choosing the right clothing makes a difference when exercising, it is also a key factor in regulating temperature while working in a physical role. This is why it is essential to consider how the company uniform can affect a worker’s thermal comfort when evaluating and specifying flame-resistant garments.

While heat stress can be attributed to external factors, such as temperature, workplace uniforms and other factors can contribute to the impact of these sources of heat. A worker may not consciously realize the effect of his or her garments on core body temperature. Just as choosing the right clothing makes a difference when exercising, it is also a key factor in regulating temperature while working in a physical role. This is why it is essential to consider how the company uniform can affect a worker’s thermal comfort when evaluating and specifying flame-resistant garments.

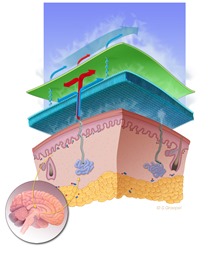

Total heat loss (THL) is a method used to measure the maximum workload or metabolic activity rate a person can sustain while maintaining thermal comfort in a garment (personal protective equipment). This measure is part of the certification for garments in the firefighting industry. THL measures the amount of conductive (dry) and evaporative (wet) heat loss that occurs through the fabric of a PPE garment.3 By placing fabric samples on specially designed plates that simulate hot, sweaty skin under controlled lab conditions, the ability of the fabric to transfer heat can be precisely measured. In hot conditions, a fabric that holds less heat is more desirable.

In hot environments, choosing garments with high THL performance is important for employees as well as management. Employees in roles with physical activity may face discomfort, physiological strain, decreased productivity and performance, and potentially increased accident rates on the job.4 A uniform with better performance can have some level of impact on these challenges.

Considerations for FR Garments in Hot Environments

When specifying PPE clothing, incorporating THL performance should be taken into consideration. THL is a measurement that combines the performance of several fabric properties, including air permeability and moisture wicking.

Certain PPE garments have a low air permeability rate, which limits evaporation and normal heat dissipation through airflow. This, in turn, increases body temperature and sweating.5 Air permeability is a key contributing factor to good THL performance.

An FR garment must not only offer breathability, but also moisture wicking. Cotton shirts are soft and comfortable in moderate temperatures, but when exposed to increased levels of sweat, they become saturated. Retaining moisture reduces a fabric's THL rating because it decreases the evaporative cooling capability. The same cotton that feels comfortable around the house becomes a liability in an extremely hot work environment.

The natural reaction to facing a hot environment in heavy clothing is to make modifications to the prescribed equipment—affecting its intended purpose. Rolling up the sleeves and leaving a coverall unzipped are common modifications that undo FR safety protocols and in some cases may add the risk of entanglements.

Considerations for FR Garments in Cold Environments

Just as garments affect body temperature in hot conditions, it is also important to consider how they affect the body in cooler temperatures. When working in extremely cold environments, safety and comfort are driven by different attributes.

Matching the right fabric technology and the appropriate insulation level to the daily tasks of a worker is critical in cooler environments. Too little insulation exposes workers to the cold, while too much insulation will cause overheating and accompanying sweat. This moisture is one of the biggest challenges for comfort in a winter clothing system. Just as in hot conditions, removal via evaporation must be managed closely because it creates cooling. A careful balance of insulation, moisture transportation, and evaporation must be achieved.

Maintaining Body Temperature in Cold Environments Through Layering

Factors to consider when specifying FR garments in cooler locations include the temperature and humidity of the environment, the level of physical activity, wind, break cycles, and the worker's size, weight, and physical condition. It is also important to consider the difference between a body in its resting state versus an active state. In colder temperatures, a body will burn calories not only to do work, but also to regulate body temperature. The body has a network of sensors that keep close track of temperature, so any area of the body that overheats get the signal to cool by sweating. Workers may need to adjust their uniform based on the activity they are performing at the time.

Layers are recommended for outdoor workers because they can be removed or added to meet very precise conditions. A session of hard work can be done in two layers to minimize overheating and sweating, and then a cool-down period can be performed with an additional insulation layer added on top. Two crew members who are at the same site, working side by side, may need completely different insulation levels based on their activity, role, work cycle, and even their physical build. Over time, workers acclimate to their environments and physical activity levels and may need to adjust their clothing accordingly.

Special attention must be paid in oil and gas, electrical, and manufacturing industries to FR protection and compliance with 2112 and 70E, especially in winter. Garments that are not FR—especially heavy-weight version—are actually additional fuel. Wearing a non-FR hoodie underneath an FR shirt will add a comfort layer, but the exposed non-FR hood is dangerous and non-compliant with FR standards. Additionally, many non-FR winter base-layers are made from Polypropylene and blends that contain Polyester. Both of these materials have low melting points and can lead to tragic injuries if exposed to a thermal incident. Section 130.7 (C) 9 of NFPA 70E states: "Meltable fibers such as acetate, nylon, polyester, polypropylene, and spandex shall not be permitted in fabric underlayers (underwear) next to the skin."

Implications for Safety Managers

FR garments should be assessed not only for their comfort, but also for how well they can contribute to the safety and productivity of the workers who wear them. By selecting FR garments with THL measures and layering in mind, safety managers can take steps to ensure employees will be able to maintain a safe and comfortable temperature in the workplace.

Lowering heat stress should be considered an important part of managing safety in a warmer workplace. By specifying garments that are lightweight, breathable, and moisture wicking, safety managers can help to prevent accidents and injuries associated with heat stress. In addition to preventing accidents, selecting the right FR garment can help increase productivity because workers may require fewer, shorter breaks and time off related to heat stress issues.6

In colder environments, it is essential that safety managers offer uniforms with layering in mind to ensure that workers comply with necessary regulations. Combining non-FR garments with an FR uniform can be extremely hazardous.

In addition to specifying optimal garments for hot and cold environments, safety managers should take the initiative to educate employees on selecting the right undergarments, should they provide their own.

The Bigger Picture

When evaluating uniform choices, specifiers should consider how each outfit will affect worker safety and comfort level, which can have an impact on overall productivity. Each garment should be assessed not only in terms of breathability, but also its moisture-wicking ability and weight. Finally, the more employees can customize their personal uniform using garment layers, the better the chances they will remain compliant.

References

1. Centers for Disease Control and Prevention

2. Bureau of Labor Statistics

3. Fire Engineering

4. Extreme Physiology & Medicine

5. Extreme Physiology & Medicine

6. Extreme Physiology & Medicine

This article originally appeared in the March 2015 issue of Occupational Health & Safety.