Arc Flash & Flash Fire Apparel: Multi-Hazard Protection

Real-world applications have brought on an increasing demand for garments that are suitable for use in environments with multiple hazards.

- By Thomas Kiddle

- Dec 01, 2014

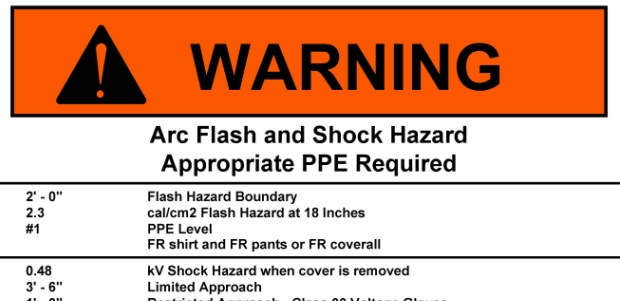

In the PPE industry, there has been an increase in the need and innovation for multi-hazard PPE--that is, garments that have been tested for their protective performance against multiple exposures that workers may encounter on the job site. OSHA 1910.269 requires that employers assess the workplace to identify the hazards employees are exposed to, and the employer is also responsible for ensuring that workers exposed to hazards from flame and electric arcs are not wearing clothing that could melt onto the skin or that could ignite and continue to burn when exposed to flames or the estimated heat energy.

The new OSHA 1910.269 standard makes this law for electric utilities and all generation, transmission, and distribution work in industrial companies. It is well known now that many garments claiming to be FR (flame resistant) actually meet no relevant performance specification. It is also well known that wearing arc rated (AR) or flash fire rated (FFR) clothing greatly improves chances of survival when an arc flash or flash fire incident does occur.

Previously, it was common to have garments marketed as FR but not certified for any hazard, but with the advent of ASTM F1506 and NFPA 2112, this has changed. In the past, garments were commonly rated separately for each hazard, but in an effort to be cost effective, practical, and to keep employees comfortable, real-world applications have brought on an increasing demand for garments that are suitable for use in environments with multiple hazards.

Reuters reported back in 2013 that fracking and the cheaper natural gas it produces were bringing steel and petrochemical plants back to the United States.1 Since then, The Wall Street Journal and others have been reporting on the major expansion of oil and gas production and the spinoff industries that have come as a result of that expansion. These developments and the rise in production have brought the need for garments that can be protective in a number of situations, such as arc flash hazards, flash fires, chemical exposure, and cold weather.

Oilfield and Petrochemical Workers

There are many hazards present in the oil and gas industry--electricity is present in all oil and gas processes. Motor control centers, switchgear, disconnects, and the power from generators are all arc flash hazards, and the risk of an uncontrolled oil release (known as a blowout) poses a fire hazard for workers. Flash fire risks increase during drilling, well servicing, and production (where well fluids are brought to the surface, separated, stored, and otherwise prepared for delivery). 2

In past years, flash fire incidents, arc flashes, and failures to provide FR clothing have raised awareness of the multi-hazard threat in the oil extraction industry. In addition to flash fire and electrical hazards, workers may be exposed to cold weather conditions while drilling in offshore areas, requiring the need for FR winter wear.

Refinery workers may be exposed to a number of hazards, including chemical, electrical, explosions, and flash fire. When maintenance and major shutdowns occur, workers can potentially be exposed to volatile hazardous materials, many of which have low flashover points. Refineries are equipped with substations and switchgear that pose an arc flash hazard.

Oil & gas workers need garments that meet these multiple hazards and that are comfortable in both low temperatures and high temperatures. They also need durable flame resistance for AR and FFR garments, which may be cleaned at home or through industrial laundering to ensure the garments maintain protection.

Some end users have expressed concern about using AR/FFR garments with contaminants. recent paper, "Study of effects of mining industry contaminations on protective properties of arc rated clothing using ASTM F1959," by Hugh Hoagland, et. al., indicates that most contaminants actually add protection. In the paper, even mixed contaminants with as much as 25 percent pure diesel fuel were not ignitable in electric arc.

Cleaning garments is critical, but many contaminants have a limited effect on garments. Even gross contamination only burns off the contaminant overwhelming the AR/FFR garment in the area of the contamination. Contaminated garments have been known to save lives.

Utility Gas and Electric Hazards

Combination utilities, such as gas and electric companies, have some workers who are exposed to both electrical and natural gas hazards at the same time, such as when turning on new services or cutting off existing meters for change overs. Gas leaks can cause an ignitable mixture to enter the air, which causes a risk of flash fire. In these events, the worker needs protection from both. Most companies choose garments such as a coverall or daily wear to meet the protection requirements for everyday hazards and add a flash suit or turnout gear for high-level exposures. Since 1997, utilities have used AR winter wear and AR rainwear in lieu of flash suits to wear over the daily wear to add protection in higher hazards. Other industries with exposure to the elements could adopt this same strategy of adding a flash suit hood, a goggle/balaclava combination, or a faceshield/balaclava to their winter wear or rainwear to make the suit into a multi-hazard garment with multiple duties. This ensures compliance in winter or rain exposures and protects from the multiple hazards in all lines of work.

Multi-Hazard Garments

The most common multi-hazard garment is one that meets the requirements of both NFPA 70E Standard for Electrical Safety in the Workplace and NFPA 2112 Standard on Flame-Resistant Garments for Protection of Industrial Personnel Against Flash Fire, but there are also garments that meet NFPA 70E and ASTM F2733-09 Standard Specification for Flame Resistant Rainwear for Protection Against Flame Hazards. There are many rainwear garments on the market that meet NFPA 70E and ASTM F2733, since these standards are written for self-certification and cover specific garments.

There are few winter wear garment options available on the market for multi-hazard threats. New winter wear products have become available that meet the requirements of both NFPA 70E and NFPA 2112, but be sure to check the labels. If a garment label says "fabric complies with NFPA 2112," the garment is not compliant. While fabrics may be certified as components, NFPA 2112 requires that all garments labeled as compliant with NFPA 2112 be certified by a third-party certification body, such as UL or SEI; it is not acceptable to claim compliance with portions of the standard. The certification body's identifying mark will be on the label. When in doubt, check their websites, where a list of compliant products is maintained. Faked labels are uncommon in NFPA 2112, but non-compliant garments abound.

The Importance of Hazard Analysis

Many industrial workers face more than one hazard while at work, and the development of multi-hazard PPE products can save employers money while keeping the worker protected and even more comfortable. The best plan of action is to conduct a comprehensive hazard analysis of the specific environment and to identify all present risks. In April 2015, it is required by OSHA 1910.269 that not only a hazard analysis be performed, but also that the PPE must match the hazard. Doing so is the first step in understanding all dangers and aids in choosing the proper PPE to prepare for multi-hazard threats.

References

1. http://www.reuters.com/article/2013/03/26/manufacturing-shale-idUSL6N0CE57M20130326

2. https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=INTERPRETATIONS&p_id=27296

This article originally appeared in the December 2014 issue of Occupational Health & Safety.