Fire Protection Systems and Procedures for Large Sites

Conducting Safe Zone drills and evacuation drills as required is a good measure of your company's safety program.

- By Gary M. Sharpe

- Dec 01, 2013

For a large campus of buildings with mixed occupancies, it is imperative to maintain their fire protection system and equipment to ensure proper function as designed during emergency conditions. Having a fire brigade on site offers a benefit above and beyond what the local authorities and facility management can provide. And with coverage 24/7, the response time can play an important role during the incipient stages of a fire.

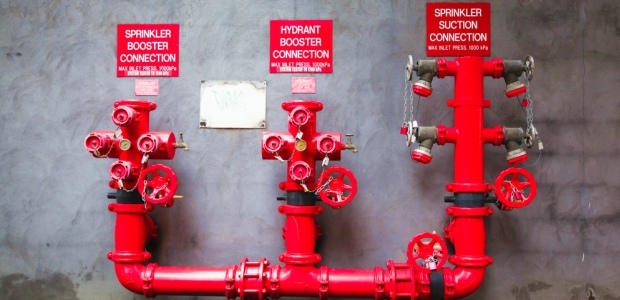

At large facilities, fire protection equipment inspection and testing can easily be performed by the on-site fire marshals. Post indicator valves, water flow alarms, tamper switches, and evacuation alarms are inspected and tested on a regular basis by the on-site trained professionals. Fire extinguishers should be visually inspected monthly, but annual inspections can be contracted out, along with refills or replacement at the required intervals to meet compliance. Most preventative maintenance schedules are computerized and provide automatic work orders forwarded to supervisors on a scheduled basis. It's the responsibility of the risk manager to ensure all frequencies are complaint to NFPA standards and local codes.

All documentation should be kept on file as a backup to any computerized systems, especially for annual audits from insurance companies and the local Authority Having Jurisdiction. The AHJ role becomes less apparent when the on-site fire brigade handles most of the minor issues. The local fire department may be used for assistance during larger emergencies but does have the authority to step in and take command if necessary. An agreement with guidelines and limitations as to when and who contacts the local fire department should be drafted and documented for reference, including an emergency contact list. On-site security plays an important role in the notification to the proper channels during an emergency.

The on-site fire marshals work closely with security to coordinate emergency evacuation drills, which test the horns, strobes, and pull stations. Some alarm testing is better during off-shift hours so as not to interrupt operations. When there are 24/7 operations that can't easily be shut down, a contingency plan should be created to simulate the drills for employees to become familiar with the emergency procedures. It is important to review your emergency response plan with all your employees and have maps posted for evacuation egress. Safe Zone maps also should be available to direct occupants where to take refuge during hazardous weather conditions or during a chemical release outside.

Fire System Testing

On-site fire marshals are responsible not only for life safety and fire protection of the campus, but also they must deal with conditions outside their control. With a large campus incorporating a fire protection system, aging facilities can become a factor. When testing fire pumps, the underground grid and its supporting pipe system is subjected to high pressures during varying environmental conditions. Colder weather and thawing can cause water main breaks as old pipes become brittle. A process and procedures must be in place to react quickly to any variations in water pressure due to a break. On-site pipefitters and excavation contractors can respond within minutes if a breach in the fire protection system is detected.

If a fire pump starts automatically because low pressure is detected, security receives an alarm and the on-site fire marshal is contacted immediately. All fire protection impairments should be handled through the fire marshal and the risk manager, and there may even be a note to the asset protection insurance company.

By testing the fire pumps and grid on a weekly basis, the fire marshal can provide some reassurance the system will operate during an emergency as intended.

Weather also can be a factor when testing outside fire protection valves in the winter, especially when the valves are locked in the open position. The advantage of an on-site fire brigade is that it can effectively manage these issues and not cost the site valuable time and money to mitigate minor, day-to-day issues.

Safety Management and Inspections

Along with a fire brigade, a good safety management system is equally important for any site. Safety inspections and good housekeeping are the basis for a solid loss prevention program. The on-site fire marshals and safety community should perform regular tours inside and out. Many projects require hot work permits, which can be issued by the fire marshal. Confined space permits and hazmat and fire extinguisher training are also part of fire brigade's support system. A final safety inspection at the completion of a project will provide confidence the job was done correctly and safely, with no outstanding issues.

Special Fire Protection Systems

On a campus with buildings that have rated areas, there are special fire protection systems in place for those specific operations. For electrical, the equipment must meet the NFPA 70E or NEC standards. For fire protection, FM-200 and pre-action systems benefit server rooms and electrical equipment, while dry systems or anti-freeze loops are in place for docking areas subject to freezing. A wet pipe sprinkler system generally covers a business office space occupancy. The deluge systems are usually found protecting cooling towers and larger outside equipment.

Storage areas utilize large drop sprinkler heads to efficiently direct large amounts of water over a given commodity. Some atriums and higher ceilings may require sidewall sprinklers with the assistance of an overhead grid. The important factor in all systems is the proper inspection and testing on a regular frequency to ensure the system will operate as expected.

From an insurance perspective, a Highly Protected Risk is what is seen as favorable from an underwriting standpoint. This is the basic philosophy that all major industry risk managers use to protect their company. However, life safety is also an equal concern. Both can be addressed through human element programs. Examples include the valve inspection program, utilizing a red tag permit program, hot works permit system, and testing and inspecting emergency lighting and alarms, among other duties that a safety team can perform. Conducting Safe Zone drills and evacuation drills as required is also a good measure of a company's safety program.

Employee Training

In order to train employees at a large site, administrative procedures and memos should be cascaded regularly to supervisors who waterfall information to their employees. It is critical to gain the support of management in order for any safety system to survive and be effective. It is the risk manager's responsibility to decide what information and direction is provided. The objective is not to overwhelm, but to inform the audience by highlighting basic key points.

For example, it can become an overwhelming challenge to provide fire extinguisher training for 5,000+ employees, so therefore it becomes more efficient to select a method based on the OSHA requirements. Most larger companies choose not to train every individual employee and instead instruct everyone to evacuate immediately. An on-site fire brigade can provide support by reducing response time and having qualified and trained personnel to address such emergencies. For a smaller company that does not have a fire brigade, it may be more beneficial to train a limited number of employees, especially in areas more prone to incipient fires such as a dock or workshop. For more hazardous conditions, such as mix rooms and paint shops, proper automatic fire protection should be in place in order not to rely on the human element to extinguish a fire.

New Technologies

With new technologies changing the way we work and the design of new structures, it becomes more important to attend workshops and learn about the latest innovations for safety and fire protection. Proper clothing and labeling for arc flash are popular topics for webinars and safety conferences. Wireless technology is making a huge impact on alarm systems and the way we detect and communicate data. Some of the major industries are beginning to utilize new technology in their designs. The leading industries strive for reliability and feasibility for all new construction projects. Ideas that reduce costs and increase efficiency are created every day, and it's these companies who take advantage and remain in front of the curve.

One advantage of being a large facility is you can utilize new technology in small steps to build confidence in its ability to benefit your company. Underground fiber optics can be replaced in portions as communications systems become obsolete. New technologies in dust collector suppression are being utilized as we learn more about the characteristics of particles and their effect on deflagration in duct work. Wireless fire alarms and panel boxes working with relays eliminate the need for underground wiring, which can deteriorate over time and fail during flood conditions.

Being a large facility does have its disadvantages, as well. Job changes, retirement, and reductions in the workforce can all play a role in how your safety management team operates. For example, a Medical Emergency Response Team (MERT) is trained and recertified every year. The idea is to have volunteers provide support during a medical emergency and be strategically located on campus for quick response. When a MERT team or safety volunteer leaves for whatever reason, a gap is created and the team is somewhat compromised. A good safety team must overcome these challenges to be highly effective. Change is imminent and can play in your favor if you predict and adapt.

So, regardless whether yours is a small or large facility, take the time to acknowledge new ideas, read the latest publications, and talk to your peers in other companies to find your benchmark. As for myself, being a Certified Lean Six Sigma Green Belt, I've learned you can usually find a way to improve if you dig deep enough!

This article originally appeared in the December 2013 issue of Occupational Health & Safety.