Electricity Remains a Serious Workplace Hazard

Lockout/tagout and rubber insulating gloves help to protect workers.

- By Laura Proctor, Srin Kuchibotla

- Aug 01, 2013

Electric shock in the workplace can take many forms, but it is always serious. A worker is servicing a piece of machinery in a factory when he or she accidentally contacts an energized buss and suffers severe shock. In another incident, an electrician is electrocuted while repairing a heating and air conditioning unit located on a commercial building's roof.

Electricity has long been recognized as a serious workplace hazard, with the first fatality recorded in 1879. The U.S. Bureau of Labor Statistics (BLS) reported 171 worker deaths resulting from electric shock in 2011.

Among the 1 million electricians employed in North America, 97 percent have experienced electric shock or injury while on the job. Even though workers in other job categories may not consider "electrical work" a standard part of their jobs, many change light bulbs and perform other maintenance tasks, energize and de-energize machines, and operate power tools. Workers in the utility, mass transit, industrial goods manufacturing, and telecommunications industries, as well as first responders, are especially at risk for electric shock.

The Body's Reaction to Electricity

It is a well-known fact that the human body will conduct electricity. A current flows any time the body comes into contact with an electrically energized part while simultaneously making contact with another conductive surface, such as metal. Once the current enters the body at one contact point, it will pass through the body and exit at the other contact point, usually the ground.

Several factors affect the severity of electric shock injuries, including the system voltage, the amount of electricity or amperage, the type of current (direct or alternating), and the body's resistance to the current. The path the current takes through the body and the length of time the body remains in contact with the current are also factors.

The body's reaction to electric shock can range from a minor tingling sensation to instant death. Even at levels as low as 3 milliamperes, current traveling through the body can cause indirect or secondary injuries, including bruising and bone fractures. A milliampere (mA) is a measurement of current, with 1,000 milliamperes per amp. For example, 120 volts/1000 Ώ is equal to .120 AMP, which is equal to 120 mA.

Consider how the body reacts when it comes into contact with the following levels of electricity:

0.5-3 mA

|

Tingling sensation

|

3-10 mA

|

Muscle contractions and pain

|

| 10-40 mA |

"Let-go" threshold

|

| 30-75 mA |

Respiratory paralysis

|

100-200 mA

|

Ventricular fibrillation

|

200-500 mA

|

Heart clamps tight

|

1500+ mA

|

Tissue and organs start to burn

|

To put these levels of exposure into perspective, the voltage levels for equipment and power sources present in many industrial facilities follow:

120V

|

Standard office wall voltage

|

240V

|

Heater circuits, small machinery, drill presses |

277V

|

High-intensity overhead lighting circuits

|

480V

|

Heavy-duty machinery

|

600V

|

Mining machinery

|

13000-15000V

|

Incoming feed from the power company

|

Protecting Workers from Electric Shock

Electric shock injuries usually occur as a result of unsafe equipment or installation, unsafe practices, an unsafe environment, or a combination of these factors. Equipment or its installation may be unsafe because of conditions such as improper grounding, loose connections, ground faults, faulty insulation, or defective or unguarded parts. Workers may put themselves at risk by failing to de-energize electric equipment during servicing or repair or using tools or equipment too close to energized parts.

OSHA has established general requirements to control hazardous energy, such as electricity, during machine maintenance or servicing. Lockout/tagout refers to specific practices and procedures developed to protect workers in the event machinery is unexpectedly energized and releases electricity. Lockout/tagout procedures involve turning off and disconnecting machinery from its energy source before servicing. The authorized employee will either lock or tag the energy-isolating device(s) to prevent the release of hazardous energy, or the worker will follow certain procedures to verify the energy has been effectively isolated.

Employers are ultimately responsible for ensuring workers take the precautions needed to prevent injuries that could result from the release of electricity.

The National Fire Protection Agency (NFPA) established NFPA 70E to protect workers from electric shock. The standard specifies that workers wear rubber insulating gloves and leather protectors any time they are exposed to energized parts operating at 50 volts or higher. Rubber insulating gloves with leather protector gloves also meet the requirements for arc flash protection when used with other properly rated personal protective equipment. Leather protectors shield the hands from injuries such as cuts, abrasions, and punctures and protect the rubber insulating gloves from physical damage.

A common misperception exists that rubber insulating gloves with leather protector gloves are generally for lineman in the utility industry. These products should be leveraged to protect workers in industrial environments, too.

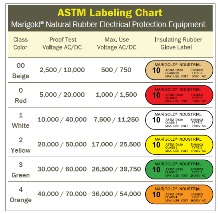

OSHA is responsible for enforcing the NFPA 70E standard, and the American Society for Testing & Materials (ASTM) drives the specifications for products that meet the standard. Rubber insulating gloves should meet or exceed ASTM D120 and must be selected for the appropriate voltage class to ensure users’ safety.

The ASTM chart below shows the appropriate class of glove for proper protection based on maximum use voltage.

Various rubber insulating gloves are available in the marketplace, although many products that protect against electrocution tend to be uncomfortable. Some of the newer rubber insulating gloves are ergonomically designed and offer dexterity and flexibility for individuals who must work with energized lines and equipment for long periods of time, such as utility workers. These products also help to reduce hand fatigue.

Glove Storage, Care, and Testing

Rubber insulating gloves are life-saving tools that must be cared for and used so they offer the wearer the required level of protection. The gloves should be stored in a protective bag away from direct sunlight and excessive heat and should be visually inspected and air tested before use and after any incident that may cause damage.

Air testing involves rolling the cuff tightly toward the palm so that air becomes trapped inside the glove -- or each glove may be inflated with a mechanical inflator. Gloves should be examined for punctures, tears, foreign objects, ozone cutting, swelling, hardening, softening, or stickiness. Punctures also can be detected by listening for escaping air.

Rubber insulating gloves may be damaged during exposure to many chemicals, especially petroleum-based products, solvents, pastes, salves, and hand creams. Any rubber insulating glove exposed to a chemical contaminant should be inspected for physical damage and cleaned with mild soap and rinsed thoroughly before undergoing inspection and electrical retesting. Many workers within industrial environments are not aware the gloves should be electrically retested every six months from the date they were issued, as per ASTM F496-08.

Training

Part of the challenge in working with electricity is that workers can neither see, smell, taste, nor hear electrical danger. They also tend to associate low voltage with low hazard and may place themselves at risk without realizing the magnitude of the threat.

Training is essential to educate workers about electricity, its properties, the possibility of injury, and the statutory requirements for proper protection. Workers must understand lockout/tagout procedures as appropriate and the importance of wearing rubber insulating gloves any time they work with energized lines or equipment. Training should be offered across all departments and plant locations and best practices should be implemented.

Summary

Anyone who works in an industrial environment or is employed in the utility, mass transit, industrial goods manufacturing, or telecommunications industry -- as well as many others -- may be at risk for electrocution. Electric shock costs workers' lives and results in painful and debilitating injuries every year.

Lockout/tagout procedures protect against electrocution, as do rubber insulating gloves, which must be worn any time workers are exposed to energized parts operating at 50 volts or higher. Some newer styles of rubber insulating gloves not only protect against electric shock, but also offer the dexterity and flexibility workers need for hours of comfortable wear.

This article originally appeared in the August 2013 issue of Occupational Health & Safety.