Zero Incident Goals Motivate Risk-Taking, Not Excellence

When excellence in safety is measured by zero failures, a self-limiting organizational viewpoint and very dangerous employee belief are created.

Zero incident programs and goals are the desires of average safety cultures, not excellently performing ones. Organizations that have achieved sustainability of excellent results in culture and performance define, measure, and motivate what they want, rather than what they don't.

Is health the absence of visible disease? If you never receive a check-up by a physician, yet you feel good and nothing appears to be wrong, have you reached your goals of health and feel confident you will live a long life with this approach?

To define health as the absence of visible, self-reporting indicators is recognizably dangerous. "Early detection, early response," the motto of Dr. Larry Brilliant, who helped eradicate smallpox and frame the thinking that shapes global infectious disease control, is a mantra we should similarly use in safety.

Within the medical community, to respond is positive, to react is negative. If the body responds to a drug, procedure, or intervention, this is positive. When the body reacts to such approaches, this is negative. When we measure success by negative reported outcomes, we are driving safety culture excellence by reaction, rather than proactive identification and response.

How we frame our goals is the difference in excellent performance and excellent results; the two are not interchangeable. If the goal is zero incidents/injuries and it is obtained, what is the measure of continuous improvement? Moreover, if an organization obtains excellent results and cannot precisely describe why, the successful results are lucky, not excellent. Whenever results are rewarded, by default, the performance that obtained the results is reinforced. Were the excellent results obtained by excellent performance, or did the group just get a little luckier this year?

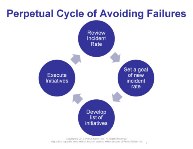

Figure 1 outlines the approach most organizations take to improve safety. Leadership will review the current incident rates, determine a new incident rate goal (either a desired rate or reduction amount), develop a list of initiatives impacting the goal, execute the initiatives, and then review the results. I refer to this widely used methodology as the Perpetual Cycle of Avoiding Failures.

Figure 1. Perpetual Cycle of Avoiding Failures

An incident is a failure in your systems, programs, and approaches to safety. When the goal, programs, and process are based on zero incidents, this translates as zero failures, thus promoting the mentality: Don't fail. Of course we do not want people to fail, but is this the motivation we truly desire: "Work hard to not fail"? When organizations establish Zero Incidents Injuries, this frames: Safety Excellence = Zero Incidents.

When excellence in safety is measured by zero failures, a self-limiting organizational viewpoint and very dangerous employee belief are created: "If safety means no incidents, then anything that I do that doesn't result in an incident or get me hurt must be safe." When this occurs, risk will be overlooked, complacency will set in, an important and healthy degree of vulnerability of risk will be lost, and organizations will be surprised by an incident that occurs out of nowhere. This will often sound like, "I can't believe that experienced, well-trained employee did that" or "How did we miss that?"

When an organization is surprised by results or events, this is an indicator the measurement systems are not properly aligned to capture and motivate both results and performance. If we set goals only based on results and individuals cannot clearly decipher what performance will contribute or deviate from the results, not only are the measurement systems misaligned, but the behavior within the culture will be, as well. What do you want in safety? What are you trying to accomplish and why? Is the motivation to achieve the goal based on organizational or individual value? What does success and excellence look like -- not just indicators and activities, but behaviorally, when you get there?

Organizations that achieve excellence set targets such as 10,000 Percent Safe™, a methodology used with clients to measure, motivate, and drive performance and organizational processes towards 100 percent safe, 100 percent of the time. Safe should be defined as not being at risk, and safety should be defined by what we individually or collectively do to create a risk-free outcome.

Definitions and terminology drive beliefs, which affect decisions and behaviors at work and away. Is your goal to have zero incidents or successful beliefs and behaviors? Both, I'm sure, but what do your measurements indicate? Next month, I will share a methodology and framework to help you move beyond failure avoidance to success-seeking goals, metrics, and performance.

This article originally appeared in the September 2012 issue of Occupational Health & Safety.