Four Questions to Shape Performance

Which behavior would make the biggest difference in yielding the results you need?

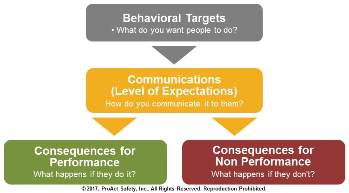

How can you get more effort out of people? Finding the answer to this has caused even the best leaders to struggle. If you want to shape performance in someone, the four questions outlined in this article will be vital to your success.

What do you want people to do? While leaders will always be held accountable for obtaining certain results, it must be clear what performance does or does not contribute to them. If injuries are to be prevented, what must an individual do to control or mitigate the risk? One long-haul trucking company was experiencing a significant amount of side-impact collisions. Through data analysis, they found one precautionary behavior could eliminate 73 percent of these incidents. To avoid these events, they wanted the drivers to engage their turn signal and listen for the audible clicking sound three times prior to looking in their mirror to begin to change lanes. What was the result? They could see and be seen more effectively, and safety results improved drastically.

A chemical manufacturing client with two facilities identified at facility A that 26 percent of injuries during the past four years could be prevented by following a few, well-established rules. At facility B, 42 percent of the injuries could be prevented with one precaution: using the tool and equipment properly.

We want vehicle accidents to be prevented and personal injuries to be avoided, so what do people need to do? There are both mandatory (expected) and discretionary (helpful) behaviors that contribute to the most desired results in any operation. Which behavior would make the biggest difference in yielding the results you need?

How do you communicate it to them? Communication is a process, not an event. It involves a sender and a receiver, and both have to be tuned in and turned on to the message. Posting information on a wall, sending an email, or speaking to a group are all only a part of the process. George Bernard Shaw warned, "The single biggest problem in communication is the illusion that it has taken place." One client identified six questions to be asked and answered every time maintenance work is to be performed in order to prevent the vast majority of injuries they were experiencing among their mobile maintenance workforce. They placed the questions on a laminated pocket card and gave it to all 88 employees.

During the first month, those who had the card on their person when approached would receive a ticket to enter a drawing with small gift prizes. The second and third month, when employees were approached, they were asked to name two of the questions on the card. Those who could were entered into the drawing. Nine months later, 100 percent of the employees could recite all six questions from memory. This simple communication tactic, coupled later with reinforcement methods, yielded an 85 percent reduction in injuries over a two-year period. If the behaviors contributing to the desired results are defined, how do you make sure others are knowledgeable of this and the information sticks with them?

What happens if they do it? While most organizations have progressive discipline, not enough have progressive recognition practices in place. If those you lead are demonstrating the desired behaviors, what positive consequences follow? Sometimes simply verbally recognizing this behavior is sufficient, as it is so often lacking. During a culture assessment of a paper mill, in a focus group discussing the topic of feedback for safety performance, one employee stated, "You know, in a few months I'll be retiring. After thirty years here, the only time they have ever talked to me about safety is when I'm doing something wrong. Just once before I retire, I wish they'd tell me when I’m doing something right." You can't effectively manage performance by exception. If someone is doing what is desired, what are the consequences?

What happens if they don't? Positive consequences for behavior are most appropriate for starting or continuing behavior and negative consequences are more appropriate for extinguishing it; but there is no guarantee that in stopping a behavior, the desired one will take its place. A balance of consequences is necessary to shape performance. What are the consequences if someone isn’t following the rules or taking a discretionary precaution to prevent injuries? There are behaviors that need to be started and stopped in many organizations; ensure you use the right type of consequence for the desired outcome you are looking for.

In many organizations, the expectations for safety are clear and revolve around zero incidents and injuries. However, do people know precisely what is expected of them to make this a reality? This is the importance of answering the first question. The second challenge, how to get it out of your head and into theirs? Now, what is your balance of consequences for shaping the desired behavior long term and making the results sustainable?

This article originally appeared in the March 2017 issue of Occupational Health & Safety.