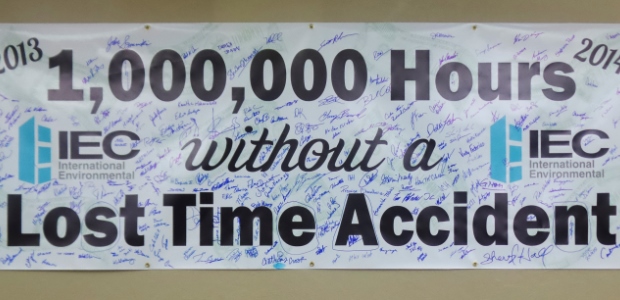

Oklahoma Company Reaches Million-Hour Milestone

"Our employees realize that IEC values their well-being and is driven to ensure that everyone makes it home to their families each night," said safety manager Stuart Hughes.

International Environmental Corp. announced Feb. 5 that its Oklahoma City manufacturing facility has reached 1 million consecutive man-hours of operation without a lost-time injury -- an accomplishment that took nearly two years.

"At IEC, our safety culture begins with a top-down mentality, along with safety messages that are infused into every aspect of our organization," said Dennis Kloster, president of IEC. "'Safety First' is not just a slogan, but a way of everyday life at IEC, which begins with each employee's first-day safety orientation and continues to echo throughout every phase of professional development."

International Environmental Corp. is a subsidiary of LSB Industries, Inc. It manufactures hydronic fan coils and provides engineered solutions to indoor air comfort challenges.

Safety manager Stuart Hughes manages the company’s formal safety program. "Some of the factors we believe attribute to the success of our program include weekly safety topics as taught by line supervisors, safety briefings at monthly company-wide communications meetings, and, most of all, the commitment of all our employees to an ongoing 'safety state of mind' in their daily jobs," he said. "Our employees realize that IEC values their well-being and is driven to ensure that everyone makes it home to their families each night. Reaching this one million man-hours milestone means that our employees are holding themselves and their fellow co-workers accountable for managing risk at all levels, and at the highest possible standards."