Construction Confined Spaces Rule Still in Proposed Stage

The latest semiannual regulatory agenda does not advance the rulemaking except to give an October 2010 date to complete analyzing comments submitted in 2008. EPA's agenda says NPRMs will be issued in July 2011 to enhance pesticide protection for applicators and agricultural workers.

No big surprises are in the new semiannual regulatory agendas published Monday by the U.S. Department of Labor, EPA, HHS, and many other federal agencies. Of note:

- NIOSH indicated it will take final action in December 2010 on changes in the Administrative/Quality Assurance sections of 42 CFR part 84, the respiratory protection rule, to upgrade quality assurance requirements; use private-sector quality auditors and testing labs in the approval program; and revise approval label requirements.

- EPA's agenda says NPRMs will be issued in July 2011 to enhance pesticide protection for applicators and agricultural workers. The latter rule would establish a right-to-know Hazard Communication program and improve pesticide safety training.

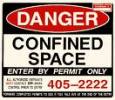

- OSHA gave an October 2010 date to complete analyzing comments submitted in 2008 about a proposed confined spaces rule for the construction industry and will initiate a scientific peer review of its draft risk assessment, also in October 2010, for a standard limiting workers' exposure to diacetyl, a food flavoring ingredient that has been linked to the lung disease bronchiolitis obliterans.

OSHA also indicated it will publish a Notice of Proposed Rulemaking in February 2011 that will be a comprehensive standard for workers' exposure to crystalline silica, and a final rule will be published the same month to complete long-awaited revisions of the general industry and construction standards for electrical power transmission and distribution, including PPE requirements for electrical protection and foot protection.

DOL's Wage and Hour Division plans to issue an NPRM in October 2011 that will update 29 CFR 552, the regulation applying the Fair Labor Standards Act (FLSA) to domestic workers.