Hearing on Labeling Rule Delayed to Oct. 7

Comments are now due by Nov. 4 on EPA's proposed rule, which would change the familiar NRR labels on hearing protection devices. The rule takes new technologies and Internet sales of HPDs into account.

The public hearing on EPA's noise labeling proposed rule has now been moved to Oct. 7, and EPA shortly will announce the new deadline to submit comments about the rule is Nov. 4, Dan Shipp, president of the International Safety Equipment Association, said today. Shipp had requested a 90-day extension of the original Sept. 4 deadline for comments on the proposed rule.

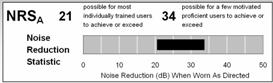

Hearing conservation professionals and manufacturers have been awaiting this rule for several years. It would allow "electronic labeling" for HPDs sold online and proposes a new label giving a range of attenuation rather than the single Noise Reduction Rating found on labels of hearing protection devices (HPDs) today.

Hearing conservation professionals and manufacturers have been awaiting this rule for several years. It would allow "electronic labeling" for HPDs sold online and proposes a new label giving a range of attenuation rather than the single Noise Reduction Rating found on labels of hearing protection devices (HPDs) today.

The rule's public docket is available at www.regulations.gov to check comments, past studies and reports on HPD performance, and other submissions. A July 2009 report prepared for EPA that is in the docket calculates costs and benefits of the proposal, and this document estimates the total U.S. market for HPDs is $459.1 million and the estimated costs of complying with the proposed rule would be 0.16 to 0.4 percent of those sales. EPA said it identified approximately 1,029 different HPDs that are currently for sale in the United States, including 403 models of ear plugs or semi-aural devices, 572 models of ear muffs sold either alone or incorporated into communication headsets, and 54 models of active noise reduction devices. An additional impulse noise reduction test would be required for approximately 156 of the 1,029 HPDs.

The proposed rule would require recurrent testing for all product categories covered by the regulations to provide a comparison of effectiveness ratings of a product over a period of time and to ensure that labels accurately reflect current effectiveness. The cost analysis considered two recurrent testing periods: three years and five years. Relabeling of an HPD would be required if the recurrent test yields a lesser and/or greater NRR that is more than 3 dB different from the corresponding transition or new product NRR values given on the product label. The cost analysis' authors stated they believe the recurrent testing requirement will encourage new testing laboratories to enter the HPD market; currently there are only four labs conducting such testing on a commercial basis, two being independent and the other two owned by HPD manufacturers.

New test protocols also are in the rule, and all HPDs would have to be tested to determine their NRRs with the new protocols. Manufacturers will be required to submit the test results to EPA within 10 business days of the transition test date.