Protect Your Hands and Your Livelihood

Preventative maintenance and care of your workers' hands may sound like common sense, but the statistics don't lie: Many are not doing enough.

- By Isabelle Faivre

- Nov 01, 2015

As a reader of this magazine, chances are good that your company has employees who make a living using their hands. Whether they are hammering a roof or running electrical on a job site, your employees' hands are essential in performing their job. And when their hands become cracked, blistered, or swollen, it's more than a cosmetic issue. This painful skin condition, known as occupational dermatitis, can not only negatively impact their job performance, but also their livelihood.

According to the Centers for Disease Control and Prevention, up to 40 percent of workers will suffer from occupational dermatitis at some point in their working lives. A deeper dive on the statistics show that 50 percent of all working time lost to industrial illness is due to dermatitis (U.S. Bureau of Labor Statistics). Just one case of occupational dermatitis can cost an employer approximately $3,500 in workers' compensation claims and an average disability of 23.9 days, according to the Journal of the American Medical Association.

The bottom line: Preventative maintenance and care of your workers’ hands may sound like common sense, but the statistics don’t lie: Many are not doing enough. Outlined below are strategies to decrease the likelihood of occupational dermatitis.

Best Practices for Healthy Hands

We all know the old adage that an ounce of prevention is worth a pound of cure. By keeping hands healthy from the start, limiting exposure to irritants and creating a company-wide hand washing regimen, you can be sure that skin conditions like dermatitis get washed away for good. Putting these best practices to use in your organization can prevent a costly skin epidemic in the workplace.

1. Use pre-work creams.

- Protective pre-work creams can be used under gloves or without gloves to help prevent skin irritation and maintain healthy skin for easier skin cleansing.

2. Wash hands properly and often.

- Apply a small amount of hand cleanser to dry hands. Rub hands vigorously together for at least 20 seconds. Scrub all surfaces, including the backs of hands, wrists, between the fingers, and under the fingernails. Rinse well and then dry hands with a clean or disposable towel. Make sure to use a towel to turn off the faucet.

3. Use the right cleanser for the job.

- There is an ongoing misconception that a hand cleanser's performance is measured by its ability to clean hands aggressively. In actuality, most cleansers far surpass the user's actual requirements. Make sure to embrace a product that takes into consideration the impact on the hands, yet is still powerful and effective for the job.

4. Choose heavy-duty cleansers without harsh abrasives.

- Grit is often added to a hand cleanser to help remove substances such as oil, dirt, and grime. However, there are a number of scrubbers, such as pumice and sand, that can cause micro-abrasions or tears in the skin. The goal is to have an effective cleansing without stripping or causing damage to the hands.

5. Opt for solvent-free cleansers.

- Many industrial cleansers contain dangerous ingredients such as petroleum distillates. Derivatives of crude oil, these solvents not only irritate hands but also are absorbed through the skin and, over time, can lead to harmful levels of toxins in the body. Low-solvent and solvent-free cleansers are a safer option.

6. Keep cleansers accessible.

- The location of hand-cleansing products can help to increase hand washing compliance. Place them where they are easy to find and see to enforce the importance of hand washing throughout the day.

7. Condition hands after washing.

- After cleansing hands, the skin can lose important oils and moisture. Apply an after-work conditioning cream to balance and replenish the moisture in the skin.

8. Use gloves where required or necessary.

- It's not always practical or safe to use gloves when working. Nonetheless, gloves and other personal protective equipment should be used whenever possible to shield hands from harsh irritants and contaminants.

9. Report skin conditions immediately.

- Make sure you and the employees in your care know that if skin problems occur, they should be reported and cared for right away to prevent further damage.

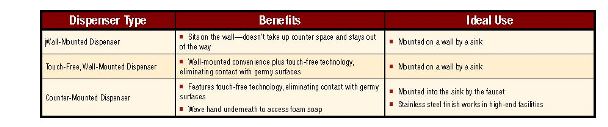

Your Guide to Choosing the Right Cleanser And Dispenser

Once your team learns more about prevention, pick the best-suited hand cleanser and dispensing system. Below is a quick reference guide that will keep your crew clean and compliant.

A healthy team is a productive team. With quality products and proper skin care, the occurrence of skin disorders in your facility or the job site can be significantly reduced, saving time and money.

This article originally appeared in the November 2015 issue of Occupational Health & Safety.