Arc Flash Training & PPE Protection

For the most effective worker protection, you're going to have to go beyond standard compliance.

- By Hugh Hoagland

- Aug 03, 2009

I received a call recently from a large electric

utility. A line worker, we'll call him Bill, had

been badly burned while performing work near

a 69kV piece of equipment. This incident illustrates

several issues that a safety professional or engineer

must consider in development of an electrical

safety training and PPE program, two of which are

not directly addressed in regulations or the consensus

standards. Thinking through a clothing system and

electrical safety program can save money and make

compliance easier and more effective.

The worker was in a 50 cal/cm2 rated winter suit.

The undergarments and outer garments were provided

by the company, but workers were given a lot of

latitude on undergarments as long as the outer shell

was compliant with the company's clothing policy.

The worker chose not to wear an arc-rated sweatshirt

even though this was commonly available in

the company's clothing catalog. Instead, the worker

was wearing a non flame-resistant T-shirt under the

sweatshirt. Though this system was in compliance

with NFPA 70E, NESC, and OSHA 1910.269, it was

not the best choice for the worker. Commonly when

doing assessments for electric utilities or any electrical

installation, companies will consider the OSHA

standards and the latest consensus standards such

as NFPA 70E and the NESC; in addition, the most

diligent companies will have their engineers or a contractor

perform detailed arc flash studies and label

equipment. Yet many companies do not thoroughly

think out their full program. This article will introduce

you to a few new things you can consider to help

go beyond standard compliance to a better-thoughtout

approach to arc flash hazards.

Understanding Arcs

When engineers talk about electric arc nowadays they

teem with enthusiasm. Many have popped up shingles

on the Internet touting their expertise in arc flash.

Most are not experts and often have little more than

exceptional knowledge of electrical theory and software

predictors. Clothing companies consider themselves

experts, too, but few really are and the vast majority

are blinded by their product mix focus. Having

internal experts is a great idea, and such professionals

should direct the internal game; getting training and

having periodic external expert program audits and

periodic system assessment audits will bring much

to improve even the best program. Equipment and

clothing vendors are a nice free source, but an independent

auditor will see things these folks will miss

and his value often will be a life-saving program tweak

that may have little or no cost.

An electric arc is a complex phenomenon that is

just being better understood in the electrical world.

The effect on clothing is interesting, and the field of

research is growing in many ways that are not getting

much publicity but that can affect the effectiveness of

your arc flash program. Usually in the popular literature

you will hear of two types of arcs, but there are

actually four types of arcs and the last two are rarely

considered in arc hazard assessments and only cursorily

addressed in the arc flash calculations.

The four types of electric arcs are:

1. Open air arc (this is the primary arc used in arc

testing)

2. Arc-in-a-box (this is used in one form for arc

testing in the EU)

3. Ejected Arc (when arc plasma hits the worker)

4. A tracking arc (most common at higher voltages,

arc plasma conducts on skin or through clothing)

Only the first two are considered in the calculations

and standards. The open air arc is well understood.

In lab testing, we control movement of the arc

for the sake of repeatability, but in real life from 480V

higher the open air arc can quickly turn into an ejected arc or a tracking arc. The tracking arc is

most common at very high voltages or during

an electrical contact. This is the arc type

that caught Bill. The standards and calculations

didn't offer Bill the best protection,

which would have been arc rated garments

over his whole body. Obviously, Bill broke

several company rules that would have prevented

this injury entirely and the company

isn't to blame, but to make a program more

"forgiving" of worker mistakes, arc rated

clothing on the whole body makes the most

difference.

Toward Better PPE

In doing arc flash calculations, some of the

effects of the ejected arc will be accounted

for by default. The IEEE 1584 equipment

configurations account for some of this

type of arc, but the tracking arc is totally

unaccounted for, even in the literature. I

recently had a utility company safety person

in a heated meeting tell me that NESC

doesn't require them to consider it at all.

This is a misunderstanding of how standards

work and their intent. Certainly one

would like simple, definable compliance to

a known standard, but OSHA standards

do not require you to only consider certain

defined hazards but to attempt to protect

from all "recognized hazards" even if they

are not easily definable.

Dr. Tom Neal of Neal Associates Ltd.

and Michael Lang of Ferraz-Shamut have

introduced us to "ejected arcs" in several

IEEE papers in the past two or three years,

but this hasn't gained much momentum

(Dr. Neal and I have an ASTM F18 taskforce

working on a test to measure this effect).

The new ASTM F2676, of which I am

taskforce chair, uses an ejected arc to rate

blankets for their resistance to arc plasma

in a defined current over time. This revolutionary

standard, developed by the ASTM

F18 committee, might enliven research for

better arc flash clothing, protective blankets,

shields, and even dramatically safer equipment.

Research using this model could also

lead to a more realistic model of arc flash

calculations (it is not the intent of the author to disparage current calculation techniques

but to help spur research using ideas

gleaned from the leading edge of clothing

testing). Dr. Neal and Lang's papers have

opened a new insight into PPE that could

lead to much better PPE and less arc flash

energy.

Researchers in ASTM have long known

PPE performs differently at different amperage

exposures. Lower amperages and

longer exposures create the same total energy,

but the PPE response is dramatically

different. Plasma ejection is usually a lower

part of the total energy in a lower amperage

arc such as the 8000 amp arc used in

the ASTM arc testing. Recent testing using

a high-speed camera and the ASTM test

set up indicate that the bulk of the plasma

doesn't reach the mannequin/panel until

the arc energy reaches 10-15 cal/cm2, and

as the energy increases more and more

plasma reaches the test surface. In higher

current arcs more of the plasma reaches

the test surface faster. Recent tests have

shown this at work.

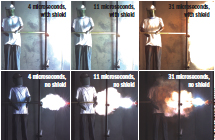

At 10kA an ejected arc plasma cloud,

as picked up on a high-speed camera (see

Figure 24), has reached a worker 34 inches

away in 23 microseconds, while a 20kA arc

has reached a worker at 34 inches in 11 microseconds

and ignited a cotton T-shirt at

that distance in about 15-25 microseconds.

Because of the newer information

coming out all the time, we recommend

including the following steps when performing

an arc flash hazard assessment

and building an arc rated clothing program

that will give better protection from

all four types of arcs:

1. Mandatory clothing for electrical

workers should offer choices, but it should be

clear, enforceable, and adequate for protection.

2. No melting "flame-resistant materials"

anywhere in the system.

3. Use (non-melting) flame-resistant

materials, especially for the upper torso,

including undergarments. Underwear is

a huge issue. I have seen three underwear

ignitions under arc rated outer garments.

4. Think about moisture management

underneath the clothing for worker comfort

and reduction of the risk of tracking arc. Arc

rated T-shirts may eliminate the use of 7-9

oz. outer shells in shirts in the next few

years. Two layers are often more protective

and more comfortable to wear.

5. Use clothing systems that provide arc

rating in multiple layers rather than just a

thick, 8 cal/cm2 shirt. Though compliance

is easier with a single garment, making all

the garments arc rated will almost always

provide better protection.

For more information, visit https://www.e-hazard.com/.

This article originally appeared in the August 2009 issue of Occupational Health & Safety.