New Research Illuminates Dangers of an Arc Flash

The results provided a new data set for the many of the hazardous characteristics of arc flash incidents.

- By David Dini

- Jan 27, 2015

An arc flash is one of the most serious electrical hazards that can occur in a workplace. The immense energy released – heat up to 35,000 degrees Fahrenheit1 – is an alarming danger to people close to the flash and can even be fatal.

An arc flash can occur when an electrical current leaves its intended path and travels through air to another conductor or to the ground. Dropped tools, equipment failure, bad installation or even dust and condensation near an energized electrical conductor can cause an arc flash incident.2 To address this, the Institute of Electrical and Electronics Engineers (IEEE) and the National Fire Protection Association (NFPA) began a collaboration 10 years ago to better understand arc flash phenomena. The two organizations, both pioneers in the advancement of workplace electrical safety, agreed that there were weaknesses in previous measurements of arc flash thermal effects and little study had been done to measure the nonthermal effects.

The project began in 2008 and was designed to improve the IEEE 1584 Guide for Performing Arc-Flash Hazard Calculations, providing methods to determine arc flash incident energy and protective boundaries. The IEEE 1584 guide then could be better used to calculate workplace safety standards, such as the 2015 NFPA 70E Standard for Electrical Safety in the Workplace and new OSHA arc flash regulations, which began Jan. 1.

The hazards of these terrifying accidents are mainly dependent on three factors: workers' proximity to the arc flash, the energy of the arc fault, and the length of time the flash occurs before some protection device interrupts the current. On average, five to 10 arc flash incidents occur each day in the United States, resulting in 7,000 burn injuries a year3. Even when their injuries are not fatal, many arc flash victims never regain their prior quality of life.

Arc flash victims' injuries are not limited to the burns from the intense heat, but can be a consequence of other non-thermal characteristics, such as pressure, sound, and intense light produced by the blast. However, precise data regarding these phenomena was incomplete and deserved more study.

Research Data Will Help Predict Hazards

IEEE and NFPA, with equipment design and laboratory test support from UL, conducted more than 1,800 arc-flash test with varying voltages, currents, electrode orientations, and configurations. Detailed information on the thermal and non-thermal effects was collected to provide a much clearer understanding of the behavior and effects of this phenomenon.

The investigation took place in two phases. The first phase tested the equipment – calorimeters, pressure sensors, spectrometers and much more – to make sure they accurately measured known qualities of arc flash phenomena. This was necessary as much of the equipment was specifically designed for this project.

The second phase of the study varied voltages, currents and the electrode configurations to test the various arc flash characteristics.

Analyses of injuries from arc flash incidents indicated that their blast pressure can damage internal organs. Other injuries to people can be caused by flying shrapnel when equipment explodes or by the blast pressure forcing them into hard objects or the ground.

However, air pressure measurement proved to be a significant challenge. The intense environment surrounding the arc flashes precluded the use of conventional pressure sensors. Using special instruments developed by the researchers, several psi (pounds-per-square-inch) of pressure were measured in the vicinity of a person who could be standing near the arc blast.

Analysis of the light produced by an arc flash gave researchers a better understanding of flash blindness, when the eye's retinal cells are affected but not permanently damaged by thermal energy. The wavelengths for visible light range from about 400 to 700 nanometers (nm), but an arc blast typically produces light in the 200-600 nm range4. The shorter wavelengths are in the ultraviolet radiation range, and the damaging effects of UV rays on eyesight are well known.

The blast pressure from an arc flash also produces plenty of noise, enough to cause hearing loss even if a person is shielded from other effects. OSHA regulations state any workplace noise should not exceed a peak 140 decibels, even with special hearing protection worn by workers. Yet tests showed that sound levels 3 feet away from the source of the blast measured between 150 and 170 decibels5. Sound is perceived by people to double in intensity every 10 dB, so a 170 dB noise is eight times louder than the 140 dB OSHA limit.

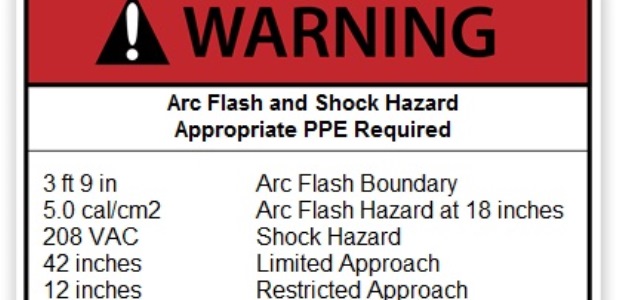

The results provided a new data set for the many of the hazardous characteristics of arc flash incidents. The new comprehensive model for arc-flash calculations generated by this research is helping to strengthen the IEEE 1584 Guide for Performing Arc-Flash Hazard Calculations. The research also pointed to the importance of personnel protective equipment (PPE) in mitigating the adverse effects of an arc flash. This importance is echoed in new OSHA safety requirements requiring employers provide the proper PPE to protect electrical workers against the hazards associated with the dangers of an arc flash.

References

1. "Understanding 'Arc Flash,'" U.S. Occupational Safety and Health Administration, 2014.

2. Ibid.

3. "Common Electrical Hazards in the Workplace Including Arc Flash," U.S. Occupational Safety and Health Administration, 2014.

4. Lee, W.J., et al., "IEEE/NFPA Collaboration on Arc Flash Phenomena Research Project," The Institute of Electrical and Electronics Engineers (IEEE), Nov. 28, 2011. White paper: Sept. 24, 2014.

5. Ibid.