Automate Routine Inspections

All environmental health and safety (EHS) programs require routine inspections of items such as fume hoods, AEDs, fire extinguishers, emergency generators, etc. – and most EHS personnel feel the administrative burden of manually transcribing and entering stacks of inspection forms into spreadsheets for recording and reporting.

But with Microsoft® SharePoint® and a mobile device such as an iPad available, the good news is that this is a problem easily solved. The combination of these readily available technologies will:

- Streamline data collection and eliminate paper forms and transcription

- Automate the workflow process through real-time analysis and automated email notifications alerting responsible parties of upcoming inspections, overdue inspections, and required corrective actions

- Make all data available in electronic format for improved and faster reporting.

Are you interested in learning how to do this? Read on for an overview of the basic steps involved in using your SharePoint site and mobile devices to help make inspections and reporting less of a burden. SharePoint is a powerful tool for automating many EHS functions, including the automation of routine inspections. Initialize the move to automation with a focus on basic (simple) inspections, which are those that involve limited data collection and where items are rated on a pass/fail basis.

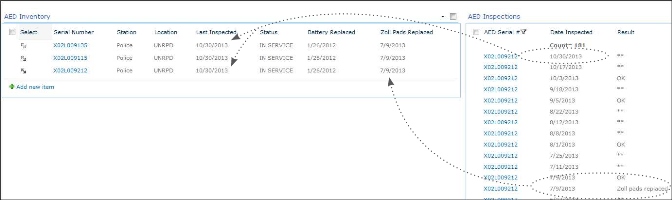

1. Create an Inventory List

Begin with the creation of an Inventory List, which details the items that require a periodic inspection including pertinent information, such as unique ID, location, serial number, item description, responsible party, status, etc. In most instances, this is already available in Excelâ format and can be uploaded directly to SharePoint. The most important field is the unique ID or serial number, which can be used to identify each item. Add additional columns to record key fields, such as last inspection date, result, and inspection notes. Another important column to add is one for the next inspection date. This is usually a calculated field using the last inspection date and a predetermined inspection frequency. The next inspection date column will be used to trigger automated reminders and late notices for the next scheduled inspection. The Inventory List serves as a single source of current inspection status of all inventoried items.

2. Create the Inspection List

A second list is created and used to record individual inspections. This Inspection List records each inspection of individual inventory items and all details of the inspection, including follow-up actions for any recorded failures. Each item is linked to the Inventory List via the unique ID field, and that column is a look-up field from the Inventory List. This look-up field allows information to be linked between the Inspection List and Inventory List. During the inspection, the inspector will select the inventory item to be inspected, fill out the short list form, and submit the inspection results.

A second list is created and used to record individual inspections. This Inspection List records each inspection of individual inventory items and all details of the inspection, including follow-up actions for any recorded failures. Each item is linked to the Inventory List via the unique ID field, and that column is a look-up field from the Inventory List. This look-up field allows information to be linked between the Inspection List and Inventory List. During the inspection, the inspector will select the inventory item to be inspected, fill out the short list form, and submit the inspection results.

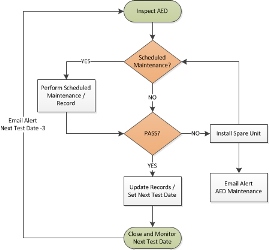

3. Create Workflows to Manage Key Deadlines and Corrective Actions

A few simple workflows will complete the application. The first workflow will update the Inventory List with the updated inspection information. The update is triggered upon creation of an inspection item by the inspector and will copy the current inspection date to the last inspected date field, along with the status field (pass/fail) and notes. A second workflow is typically triggered if the inspection fails in some way. This workflow might send an email to those who need to respond with repairs or subsequent follow-up inspection, and wait for a response. Tracking corrective actions and their resolution is often poorly documented in programs due to the administrative effort and is often cited by regulatory agencies.

A few simple workflows will complete the application. The first workflow will update the Inventory List with the updated inspection information. The update is triggered upon creation of an inspection item by the inspector and will copy the current inspection date to the last inspected date field, along with the status field (pass/fail) and notes. A second workflow is typically triggered if the inspection fails in some way. This workflow might send an email to those who need to respond with repairs or subsequent follow-up inspection, and wait for a response. Tracking corrective actions and their resolution is often poorly documented in programs due to the administrative effort and is often cited by regulatory agencies.

Notification of upcoming inspections or overdue corrective actions is easy and is usually accomplished via third party software such as Bamboo Alerts or Nintex workflow, if available. Third party solutions are required due to limitations in SharePoint Designer.

4. Connect Mobile Devices

The final step is to allow the collection of inspection information by a mobile device for field data entry. The easiest way to accomplish this is via the SharePlus™ app available for iOS and Android devices (~$20). This app allows users to access and update both Inventory and Inspection Lists on their mobile phones or tablets, even when no Wi-Fi is available. List views can be created and adjusted in SharePoint as needed to customize the form view on the mobile device and streamline the inspection process. This may take a few inspections to test and perfect, but it is relatively simple to do and well-worth the effort.

The Capacity of SharePoint

This simple application can be applied to many types of inspections and will save many hours of administrative time. It's just a single example of the capacity of SharePoint to automate EHS data collection and processing, saving administrative time for program analysis and improvement.

You can automate routine inspections such as these:

- Eyewash & shower stations

- Fire extinguishers

- Fume hoods

- Emergency generators

- AEDs

- Spill kits

- First aid kits

Robert Foster, M.S., is director, Automation Services, for Environmental Health & Engineering Inc. (EH&E). He organizes the development of Microsoft SharePoint-based applications to support both small and large Environmental Health & Safety and Biosafety programs. Applications uniquely focus on utilizing in-house expert knowledge to develop customized solutions on this increasingly common collaboration platform. Contact him at 800-825-5343 or [email protected]. EH&E (www.eheinc.com) is a leader in environmental health and safety consulting and has provided EHS program development, compliance and oversight services for a wide range of industries for 25 years. From this wealth of EHS program experience, the company offers a unique series of compliance software solutions designed on the commonly available SharePoint platform.

Posted by Robert Foster on Aug 12, 2014