Fall Protection FAQs: Five Things You've Been Meaning to Ask

Proper equipment and ongoing training save lives and boost employee morale.

- By Craig Firl

- Jul 01, 2014

No matter what industry you work in, the importance of workplace safety has likely been drilled into your head since day one. You must use the proper equipment, receive the right training, and always follow safety protocols. Making safe decisions has probably become instinctive, built into your everyday routine. However, every job site has its own unique challenges and requirements, which can leave even the most experienced workers feeling unsure of what is required. Below are five common questions that Capital Safety's expert team hears from workers at height across the country.

1. I have fall protection equipment from a previous job. Can I use the same equipment on a new job site?

There is no simple answer to this question. Every job site is different and contains its own unique challenges and fall hazards. While most fall protection equipment today is manufactured to be versatile, that doesn't guarantee that what was used on the last job is the best solution for a new job site. Some applications require job-specific equipment to ensure the safety of workers. For example, those working in fields that do welding or electrical maintenance require a harness made with special materials that offer fire resistance and arc flash protection. The type of lanyard or self-retracting lifeline needed may also change, depending on things such as anchorage locations, fall clearance, and the set-up of the job site.

Fall protection equipment will not keep workers properly protected unless it is the right equipment for the job and is used properly. Don't forgo researching the job site and auditing safety equipment in an effort to save money. Instead, work with a qualified distributor or equipment manufacturer to figure out exactly what is needed. If you don’t have the right equipment for the job, you’re not fully protected.

2. What is fall clearance and swing fall?

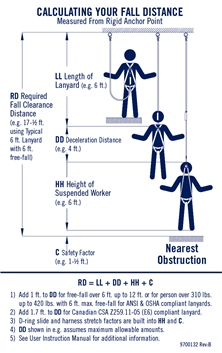

Fall clearance is the minimum vertical distance a worker needs in the event of a fall to safely arrest the fall and avoid striking the ground or an object below. It's crucial to understand that fall clearance is more than just the simple measurement from a worker to the nearest obstruction. Other factors to consider include deceleration distance, the height of the worker, and whether a shock-absorbing lanyard or self-retracting lifeline is being used. In fact, a correct calculation could mean the difference between serious injury and a safely arrested fall. Diagrams and formulas are available for calculating fall clearance at www.CapitalSafety.com.

Fall clearance is the minimum vertical distance a worker needs in the event of a fall to safely arrest the fall and avoid striking the ground or an object below. It's crucial to understand that fall clearance is more than just the simple measurement from a worker to the nearest obstruction. Other factors to consider include deceleration distance, the height of the worker, and whether a shock-absorbing lanyard or self-retracting lifeline is being used. In fact, a correct calculation could mean the difference between serious injury and a safely arrested fall. Diagrams and formulas are available for calculating fall clearance at www.CapitalSafety.com.

If the distance between the anchorage point and the nearest obstruction is less than the calculated fall clearance distance, the fall arrest system cannot effectively protect a worker from the dangers of a fall from height.

A swing fall is a pendulum-like motion that can occur when the worker falls and their connector device is in a position located horizontally away from the anchorage point and not directly above the worker. In such situations, swing fall distance must also be taken into account. Because a swing fall generally lengthens the overall vertical fall distance, clearances must be appropriately adjusted. (Additional diagrams are also available to describe swing fall hazards at www.CapitalSafety.com).

3. What should I do if someone falls on the job site and needs to be rescued?

Even with the very best fall protection system in place, it's still possible for a fall to occur. Don't risk being unprepared and poorly trained on how to handle such a situation. OSHA regulations require that you have a comprehensive, written rescue plan in place that all workers are trained on and can access at any time. We and many other equipment manufacturers offer sample rescue plans as a starting point for developing your own.

Once there is a comprehensive plan in place, there are four crucial steps to follow when a fall occurs:

- Respond to the fall. The ANSI Z359 fall protection code states that no more than six minutes should pass from the time a worker falls to when he is reached. OSHA requires the provision of medical aid to the fallen worker within four to six minutes. These time limits are put in place to help mitigate the risks of unconsciousness or further injury of a suspended worker.

- Monitor the fallen worker. Continuously communicate with the worker, especially if he or she is suspended for a prolonged period of time. Encourage the fallen worker to move his arms and legs to promote blood flow to the extremities. If the worker describes or displays symptoms of dizziness, fainting, nausea, breathlessness, low heart rate, low blood pressure, or loss of vision, notify emergency medical services immediately because these are warning signs of a more severe injury, such as suspension trauma.

- Follow the rescue plan. Use the rescue plan to determine safe next steps and have a trained employee rescue the fallen worker. The best rescue plan avoids putting the rescuer in harm's way.

- Transport the worker to a safe area. In most situations, the ground is the safest level, but some job sites may require transporting the worker to a different area, such as the interior of a building. Once the worker is in a safe area, determine whether first aid treatment needs to be administered or if the fallen worker needs to be transported to a hospital.

Once the fallen worker is safe and the immediate emergency is under control, be sure to take all safety equipment involved in the incident out of commission until a qualified person can inspect it.

4. I've heard people talk about the ABCDs of Fall Protection. What is that?

A typical personal fall arrest system is made up of four necessary components. The ABCDs of Fall Protection is a commonly used abbreviation to remember the following four components.

Anchorage

The anchorage is the secure point of attachment. Anchorage connectors vary by industry, job, type of installation, and structure. It must be able to support the intended loads and provide a sufficient factor of safety.

Body Support

A full body harness is the most common type of body support. Harnesses distribute fall forces over the upper thighs, pelvis, chest, and shoulders and provide a connection point on the worker for the personal fall arrest system.

Connector

A connector, such as a shock-absorbing lanyard or a self-retracting lifeline, connects a worker's harness to the anchorage.

Descent/Rescue

These are devices used to raise or lower a fallen or injured worker to safety or retrieve the worker from a confined space. It is not uncommon for this component to be overlooked.

5. What is the difference between OSHA and ANSI?

OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) are both important organizations focused on keeping workers safe. While there is some overlap between the two, their roles are ultimately different, and they should not be confused.

OSHA is a division of the U.S. Department of Labor charged with setting and enforcing safety regulations in the workplace. OSHA also provides training, outreach, education, and assistance to workers in order to facilitate awareness and understanding of such regulations. OSHA regulations are governing law and therefore mandatory in nature, meaning all workplaces/employers must comply. Those who do not comply can face serious consequences, including citations and hefty fines.

ANSI exists to promote and facilitate voluntary consensus standards, some of which are aimed at improving worker safety on the job, such as the Z359 series for fall protection. ANSI standards are intended to serve as recommended guidelines and often go more in depth than OSHA regulations. However, unlike OSHA regulations, ANSI standards are not mandatory, and following them is not required by law. While manufacturers and employers can choose to ignore ANSI standards without facing any monetary penalty, doing so could (and often does) place worker safety in jeopardy.

While OSHA regulations are established to ensure safe working conditions, due to the lengthy process involved in updating regulations, they often fall short of delivering the most comprehensive and up-to-date safety information. ANSI standards, on the other hand, are generally more current, requiring revision or reaffirmation every five years, and represent the thinking of industry experts from all stake holders. In general, these consensus standards serve as more all-inclusive, easy-to-understand safety reference materials. Do not overlook the importance of ANSI standards and the value of being ANSI compliant.

Even though OSHA and ANSI are separate organizations, the regulations and standards related to safety and health are of paramount consideration for both. In that sense, they are deeply intertwined and should be used together to enhance and strengthen the safety of workers. Those who truly put safety first are known to actively follow all applicable OSHA regulations and ANSI standards.

Fall protection can seem like a daunting task, but it doesn't have to be. Proper equipment and ongoing training save lives and boost employee morale. Contact your safety equipment manufacturer if you have additional questions on how to stay safe at height.

This article originally appeared in the July 2014 issue of Occupational Health & Safety.