Workforce Woes: Maintain Productivity Amid a Skilled Worker Shortage with Compact Hydrodemolition Robots

Some contractors are finding a productivity boost from another type of equipment: Hydrodemolition robots.

- By Keith Armishaw

- Jun 17, 2020

If you had to guess, what would you say is the number one concern of today’s contractor? Managing tight deadlines? Ensuring worker safety? Keeping up with developments in technology? How about input costs?

According to the Associated General Contractors of America, what keeps contractors up at night is the availability—or more accurately, the lack—of skilled labor. In fact, 80 percent of firms expect it will remain difficult to hire qualified workers in the coming months due to older workers leaving the profession during recession years and younger workers seeking less labor-intensive jobs. In addition, the world construction market is projected to grow 85 percent by 2030, adding stress to an industry already struggling to keep up with demand.

The circumstances for concrete repair contractors are particularly challenging. In an October 2019 news release, the Portland Cement Association predicted cement consumption would continue growing over the next two year—1.7 percent in 2020 and 1.4 percent in 2021—all while the skilled labor force continues to dwindle.

To add to the dilemma, contemporary concrete demolition methods are not exactly scalable; the only way to increase output is with more workers. Many concrete repair contractors rely on manual concrete removal methods, such as pneumatic paving breakers or hand lances that use a high-pressure water jet. However, some contractors are finding a productivity boost from another type of equipment: compact Hydrodemolition robots. The system allows a project to be completed as much as 10 times faster than with hand lances, reducing fatigue, labor costs and improving safety and quality of work along the way.

More Work, Fewer Workers

Though widely used, hand lances do little to advance concrete contractors’ goals of improving productivity to match growing demand. The tools, inherently saddled with issues of fatigue and injury, drive up workman’s compensation costs. And due to design limitations, hand lances provide limited value in terms of power, precision and productivity.

Some are finding that the solution to increasing productivity lies in recruiting machines rather than additional people. Many concrete repair contractors are turning to remote-controlled Hydrodemolition robots to improve workforce utilization and jobsite productivity. These machines allow workers to stand at a safe distance and monitor the equipment, reducing operator fatigue while simultaneously increasing precision and efficiency.

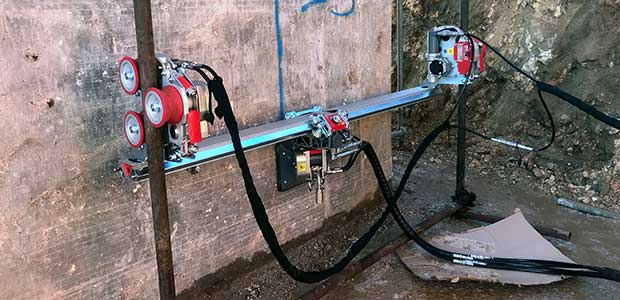

Some manufacturers now provide the same advanced technology of standard Hydrodemolition robots in lighter, smaller systems. At a fraction of the cost of standard machines, compact robotic Hydrodemolition systems provide a cost-effective mode of entry for concrete repair contractors who want to add Hydrodemolition technology to their operation.

The Cost of Being Tired

Tired workers can be a significant drain on jobsite productivity, dragging out project completion and racking up unnecessary labor costs. The National Safety Council estimates that reduced performance due to fatigue can cost businesses up to $3,100 per employee annually.

Hand lances cause workers to fatigue quickly because they must resist back thrust as they operate the water jet. A worker using a 30,000 psi hand lance must constantly fight up to 54 pounds of force for normal operation. The physical exhaustion translates to less productivity and greater cost for the business owner.

Remote-controlled compact robotic Hydrodemolition systems, however, combat worker fatigue. Ergonomic controls mounted at waist height allow operators to work for hours without tiring, improving productivity and allowing concrete repair contractors to scale their operations without spending more on labor resources.

Productivity from Safety

Because they combine high-powered water jets with the possibility of human error, hand lances are inherently dangerous. The pressurized water they emit poses a threat to anyone nearby, even if they are wearing protective gear. This can be especially risky on a busy jobsite where workers are often focused on their own tasks rather than being wary of the location of the hand lance.

Compact Hydrodemolition systems allow operators to stand back from the area where concrete is being systematically removed, keeping them safe from flying debris and silica dust. Unlike hand lances or handheld pneumatic tools, these compact robots don’t require workers’ bodies to absorb any shock from the concrete removal process, thereby preventing injuries to hands, wrists, shoulders and backs that are common with regular operation of handheld tools.

Since compact Hydrodemolition robots can be mounted on standard scaffolding and work in tight spaces, including next to ledges, concrete repair contractors also save the time of setting up fall abatement systems. Operators can remain a safe distance from fall risk areas, eliminating the need for time-consuming assembly and tear-down of these systems.

Eliminating the Power Struggle

Though some hand lances can be operated at comparable pressure to compact Hydrodemolition robots, they fall short in terms of water flow rate and reaction force, inhibiting their ability to remove broken or damaged concrete at rates fast enough to handle tough projects.

Achieving a high-water flow rate and reaction force is vital for water jetting tools to achieve the depths of removal necessary to complete most concrete structure restoration jobs. The lower flow rate of hand lances makes it difficult to remove concrete beyond a depth of a half of an inch. While hand lances can only safely offer 5 to 6 gpm, compact Hydrodemolition robots can safely handle about 30 gpm. These machines can handle up to 1,000 newtons (225 pound-force) of reaction force compared to only 250 newtons (56 pound-force) produced by hand lances.

What does this mean in terms of productivity? Imagine a large parking lot in need of spot work. Bringing a hand lance to the job may get it done, but much slower than robotic alternatives. Compact Hydrodemolition robots can remove concrete at rates of 10 cubic feet per hour, compared to just 0.5 or 1.0 cubic feet for a hand lance. That means a job completed almost 10 times faster with a compact Hydrodemolition robot rather than a hand lance.

Robotic Precision

Compact Hydrodemolition systems can work faster, more efficiently and with more precision than a human behind a hand lance. This eliminates the unknowns in performance and provides enhanced and consistent productivity.

The robots can also be programmed to maintain a specific depth of removal, a feat impossible from handheld water jetting tools. Constant depth control eliminates the unknowns in performance, giving concrete repair contractors more control of their projects and assurance that they can meet promised deadlines.

Rest for the Stressed

Now more than ever, construction businesses need to adopt high-tech equipment to retain their workforce, increase efficiency and improve jobsite safety. With no end in sight to the skilled labor shortage, contractors can—and must—adapt new methods into their business model to thrive in a changing economic environment.

Aquajet, which was acquired by Brokk AB in 2016, is known as the industry leader in Hydrodemolition machines and solutions, both in terms of quality and volume. The company’s headquarters and production facilities are in Holsbybrunn, Sweden. Similar to Brokk, Aquajet sells globally. For more information: Aquajet, Brunnsvagen 15, SE-574 53, Holsbybrunn, Sweden; +46 383 508 01; [email protected]; www.aquajet.se; YouTube; Facebook; LinkedIn and Vimeo. For more information: Brokk Inc., 1144 Village Way, Monroe, WA 98272; 800-621-7856; [email protected]; www.brokk.com; Facebook; YouTube; LinkedIn and Twitter.