Rainwear Performance Considerations for Electric Utility Workers: Innovative Fabrics Bring Protection and Comfort

Utility workers need garments that not only provide protection from arc hazards and foul weather, but also ensure that they can be seen by others, reducing the risk of visibility-related workplace accidents.

- By Mark R. Miller

- Jul 15, 2019

Every day, utility workers put their lives on the line. Operational conditions can pose serious threats. Heights are steep. Voltage is high. Weather is volatile. The risk of an electrical arc incident is ever looming.

The job requires skill, dexterity, and patience; in-depth knowledge of electricity, wire repair, and safety protocol; and clothing that keeps workers safe, dry, and protected in all conditions. The ideal garments for electric utility workers provide durable protection and exceptional comfort while meeting flame-resistant (FR) and arc-resistant (AR) requirements. For optimally performing rainwear, utility workers and safety managers should select garments that are waterproof, windproof, breathable, and highly visible. Yet traditional protective rainwear is often stiff, heavy, and not breathable. Protection comes at the sacrifice of comfort or vice versa.

Specialists in the science of comfort and protection are making life better for electric utility workers through new fabric technologies. These materials provide not only optimum protection, but also maximum range of motion, minimal bulk, and improved comfort. As a result, workers can stay on the job longer, maintain focus, and enjoy freedom of movement and breathable comfort in all weather.

Protection from Arc Flash

Electric arcs pose serious safety hazards for electric utility workers. In an arc flash incident, temperatures can reach 35,000° Fahrenheit, with exposure to electrical explosion or discharge resulting in burn injury or death. According to the National Fire Protection Association (NFPA), every year, more than 2,000 people are admitted to burn centers with severe arc flash burns. Proper protective clothing is key to minimizing and possibly preventing burns.

The American Society for Testing and Materials (ASTM) has developed a performance standard for Arc- and Flame-Resistant Rainwear, ASTM F1891-19. Passing this standard ensures that utility worker gear meets minimum thermal and physical performance when exposed to a laboratory-simulated electric arc. This standard also sets minimum requirements for waterproofness on the garment fabric and sewn seams.

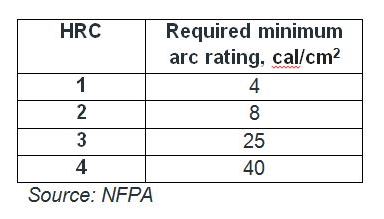

FR/AR clothing is rated by a hazard risk category (HRC) and an arc rating based on the lower of the arc thermal protection value (ATPV), or the break-open threshold energy (Ebt). HRC levels range from HRC 1, low risk, to HRC 4, high risk and requiring FR clothing. The HRC is used to determine the arc rating a garment requires to complete a given job task. The higher the arc rating value, the greater the protection.

For maximum worker protection, look for fabrics that offer arc flash protection for the life of the garment, including after wash cycles, and that meet or exceed the standard's requirements.

For thermal protection, ASTM F1891 sets a minimum of 5 calories per centimeter squared (cal/cm2) arc rating (HRC 1) after three wash cycles. In practice, safety managers may require a higher arc rating for the personal protective equipment they specify for their utility workers. This standard also does not have a breathability requirement, which can compromise worker comfort. FR rainwear meeting this standard will be identified on the product label.

Rainwear made with fabrics that meet performance standards and deliver comfort should be a top consideration in any purchase. ASTM F1891 sets minimum requirements for arc flash protection but does not address other important aspects of rainwear, such as breathability. Newer FR/AR fabric technologies can better address protection and comfort, reducing the need for trade-offs.

Protection from Foul Weather

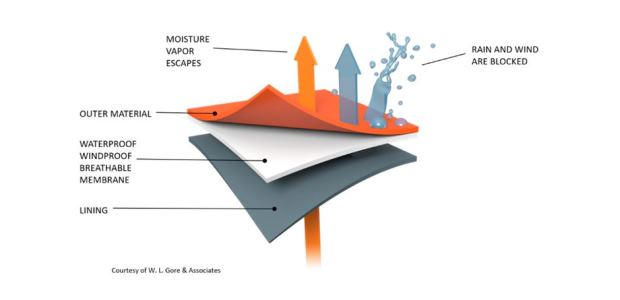

In severe weather, high-performance arc-rated rainwear must meet three criteria: 1) waterproof, 2) windproof, and 3) breathable.

What is waterproof?

Rainwear must be truly waterproof in inclement weather, engineered to repel nonstop precipitation. Various tests are used to measure waterproofness, including ASTM D-3393, which is included in ASTM F1891. Fabrics with such coatings as polyurethane or polyvinyl chloride may offer initial waterproofness but can lose their effectiveness over time. And fabrics with just a water-repellent finish can be completely ineffective in keeping water out when the garment experiences any pressure, such as from taking a knee or leaning against an object. Look for garments with an integrated, durable, waterproof, breathable membrane.

Ideally, the fabric will have low water pick-up, meaning that the garments won't get heavy in the rain from water saturating the shell fabric. Less water pick-up also means faster dry-out, reducing the cold, clammy feeling that comes from using damp gear.

Garments should be rigorously tested for waterproofness under extreme weather conditions. Standards do not capture all potential conditions, so testing beyond the standards, including style qualification and simulated or real-life storm testing, is important.

What is windproof?

Arc-rated rainwear must be totally windproof to protect workers in cool and windy weather conditions. Wind chill can make the air outside feel more than 10 degrees cooler than it really is! The most effective fabrics block the wind while also allowing the body's moisture vapor to escape.

Windproofness is determined by measuring air permeability through the fabric and associating this measurement with the resulting heat loss at different wind speeds. Fabrics with an air permeability rate of 1.0 cubic feet per minute (cfm) or less are considered truly windproof.

What is breathable?

Effective arc-rated rainwear needs not only to protect against liquid penetration, but also to be highly breathable. In one hour, our bodies can release ¼ cup of perspiration at rest, more than 4.5 cups during vigorous activity, and almost 17 cups during extremely heavy exertion. If this moisture vapor can't escape from the utility worker's rainwear to allow for evaporative cooling, the worker will quickly become wet and uncomfortable, losing focus and risking injury. Look for fabrics that let sweat evaporate through the fabric membrane, while also blocking wind and water, to help keep the wearer comfortable.

Fabric breathability can be evaluated by the Ret test. This widely accepted test in comfort science, designated by ASTM F1868, Part B, and ISO 11092 methods, measures a material's resistance to sweat evaporation. The lower the resistance, the more breathable the fabric.

High Visibility

Utility workers need garments that not only provide protection from arc hazards and foul weather, but also ensure that they can be seen by others, reducing the risk of visibility-related workplace accidents. The American National Standards Institute (ANSI) and the Canadian Standards Association (CSA) have set requirements for high-visibility clothing that reduces accident risk. ANSI 107-15, the American National Standard for High-Visibility Safety Apparel and Accessories, and CSA Z96-15, an equivalent Canadian standard, should also be met.

Look for arc-rated rainwear made from innovative fabrics that are Hi-Vis Yellow or Hi-Vis Orange to contrast with the surrounding environment. Also, these fabrics eliminate the need to wear an additional vest when responding to service calls in high-traffic areas.

Testing

For maximum performance, fabrics need to be tested beyond existing standards and user evaluations—ideally through a four-part process:

1. Material testing. Materials are tested in the laboratory for waterproofness and arc flash resistance; delamination resistance; seam-tape adhesion; flexibility in extreme temperatures; and durability in rain.

2. System-level testing. Garments and/or garment systems are tested using instrumented manikins to measure the garments’ breathability, freedom of movement, and burn protection.

3. Human performance. Subjects test how the fabric feels, works, and wears in controlled chamber conditions. These chambers simulate environmental conditions while the test subjects perform different activities. Typical output measures skin temperature, heart rate, and other physiological responses.

4. Field trial. Garments are manufactured and put through a user trial. Feedback is collected on protection, comfort, and durability—especially useful in helping safety managers make decisions.

Into the Future

For the electric utility industry, the future is here for new fabric technologies. The newest FR/arc-rated rainwear can be protective and comfortable, too. One performance element doesn't need to be sacrificed for the other. As fabric technologies continue to evolve, the industry can look forward to work garments that are lighter, stronger, and safer—enabling every electric utility worker to brave the elements in comfort and confidence.

Selecting Rainwear for Your Electric Utility Workers: A Checklist

If you're in charge of safety in your workplace, consider the following questions to ensure the best choice in FR/AR rainwear.

Protection

Is the fabric:

- Proven in exceeding ASTM F1891 requirements, protecting against all heat, flame, and electric arc exposures?

- Waterproof, at least to 30 psi pressure per ASTM F1891, and windproof (permeability rating of 1.0 cfm or less)? Has the finished garment been storm-shower tested for waterproofness under the most extreme weather conditions?

- High-visibility, meeting ANSI 107-15 or CSA Z96-15 requirements for crucial visibility, even in diminished-light and/or high-traffic environments?

- Durable, resisting abrasion, rips, and tears and maintaining its physical integrity, even after direct exposure to flame and extreme low temperatures?

- Colorfast (doesn't fade) when exposed to sunlight and after multiple cleaning cycles?

Comfort

Is the fabric:

- Lightweight, providing maximum freedom of movement?

- Highly breathable, allowing for sweat evaporation to help regulate body temperature and reduce moisture buildup?

- Fast drying?

- Easy to clean and care for?

This article originally appeared in the July/August 2019 issue of Occupational Health & Safety.