Respirators—Mandatory or Voluntary, Know the Difference

It's more important than ever for employers to stay focused on OSHA regulations—not only to avoid citations and costly fines, but also to protect the organization's most valuable asset, the employees.

- By Steve Adamavich

- Feb 01, 2017

Most people do not think twice when they pick up and use a respirator in the workplace. This "grab and go" mentality has its consequences. When employees are not provided with proper personal protective equipment (PPE) and specific procedures to ensure the equipment's effectiveness, health hazards such as cancer, lung impairment, or even death can occur. Conversely, if employers provide respirators without knowing the regulations, they run the risk of being out of compliance.

A few years ago, two OSHA inspectors were at a client's facility to conduct an inspection due to an employee complaint from a recent forklift accident. While escorting the OSHA inspectors to the loading dock, one of them noticed a dust mask on a work bench. In turn, the inspector asked the plant manager whether the employees were required to wear them. The plant manager stated that all employees were required to wear dust masks when doing a specific job. As a result, the company received more than $10,000 in fines, none of which were in relation to the original complaint of the forklift accident. All of the fines were because the company did not follow the respirator regulations (fit test records, training, program, etc.).

The use of respirators is the last line of defense and should be considered after all other options have been addressed as outlined in the hierarchy of controls. If exposures cannot be reduced to levels deemed safe under OSHA regulations through substitution, elimination, engineering, administrative or work practice controls, then the OSHA Standard 1910.134 may apply depending on the contaminate.

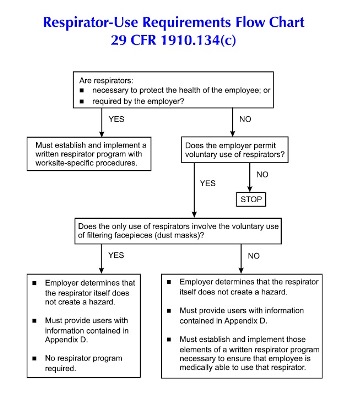

There are specific detailed respiratory protection requirements of this OSHA standard, which apply depending on the following circumstances (see Respirator-Use Requirements Flow Chart):

- Mandatory or emergency use

- Voluntary use—disposable dust mask

- Voluntary use of a respirator more than a disposable dust mask

Whether it's for mandatory or voluntary respirator use, those responsible for safety in their organizations should know the difference and provide specific details to employees for proper protection.

- Mandatory or Emergency Use: If a respirator is required to be worn as part of the job requirement or the use is required during an emergency, then the entire OSHA Standard 1910.134 applies. This consists of filtering facepiece respirators, including disposable dust masks. Along with the equipment, employers must establish and implement a written respirator program and specific workplace procedures. As seen in column one of the OSHA Regulations Section 1910.134 Summary Sheet, all program requirements apply except Appendix D.

- Voluntary Use: Consists of a filtering facepiece, such as a disposable dust filtering facepiece respirator. In this case, the only requirements are that the respirator be stored and maintained so that its use does not present a health hazard to the user and that the employer provide employees with Appendix D. This can be seen in column three of the OSHA Regulations Section 1910.134 Summary Sheet.

- Voluntary Use of a Respirator More than a Disposable Dust Mask: Consists of a respirator other than that of a filtering facepiece, such as half masks or full face cartridge respirators. In this case, Appendix D still applies, but other specific program requirements listed in column two of the OSHA Regulations Section 1910.134 Summary Sheet apply. This includes medical evaluations, designating a program administer, and developing procedures for cleaning and repairing respiratory equipment.

Respiratory Protection Program

In OSHA's list of 2016 Top Violations, respiratory protection ranked No. 4 with a total of 3,573 violations cited. The top 5 sections cited were:

- 1910.134(e)(1) Medical evaluation for respiratory protection: 615 violations

- 1910.134(c)(1) Respiratory protection requirement: 499

- 1910.134(f)(2) Respirator fit testing: 341

- 1910.134(c)(2)(i) Employer must establish respiratory program: 241

- 1910.134(d)(1)(iii) The employer shall identify and evaluate the respiratory hazard(s) in the workplace: 235

It's more important than ever for employers to stay focused on OSHA regulations—not only to avoid citations and costly fines, but also to protect the organization's most valuable asset, its employees. When mandatory or voluntary respirators are being used, an appropriate written respiratory protection program must be in place. This avoids the "grab and go" mentality and ensures the health and wellness of workers. A respirator program must include work site-specific procedures that address the following:

- Proper respirator selection

- Medical evaluations of employees required to use respirators

- Fit testing procedures for tight-fitting respirators

- Procedures for proper use of respirators in routine and reasonably foreseeable emergency situations

- Procedures and schedules for cleaning, disinfecting, storing, inspecting, repairing, discarding, and otherwise maintaining respirators

- Procedures to ensure adequate air quality, quantity, and flow of breathing air for atmosphere-supplying respirators

- Training employees in the respiratory hazards to which they are potentially exposed during routine and emergency situations

- Training employees in the proper use of respirators, including putting on and removing them, any limitations on their use, and their maintenance

- Procedures for regularly evaluating the effectiveness of the program.

All of these must be addressed for mandatory and emergency respiratory use.

Training Requirements

Understanding why, when, and how to use a respirator is more complicated than operating the respirator itself. Training helps to eliminate improperly worn, poorly maintained or nonfunctional equipment that leads to a false sense of security, which can be worse than no protection at all. OSHA's training provisions require the employer to ensure that each employee can demonstrate knowledge of at least the following:

- Why the respirator is necessary and how improper fit, usage, or maintenance can compromise the protective effect of the respirator

- What the limitations and capabilities of the respirator are

- How to use the respirator effectively in emergency situations, including situations in which the respirator malfunctions

- How to inspect, put on and remove, use, and check the seals of the respirator

- What the procedures are for maintenance and storage of the respirator

- How to recognize medical signs and symptoms that may limit or prevent the effective use of respirators

- The general requirements of the respiratory protection regulation.

Training must be conducted prior to respirator use. Retraining is required annually, whenever changes in the workplace or type of respirator would make previous training obsolete, when there are indications that the employee's knowledge is inadequate, and under any other circumstances where retraining would be necessary to ensure safe respirator use. The only exception is the voluntary use of filtering facepiece respirators (dust masks). As previously stated, those individuals need only to be provided with Appendix D. When reviewing this with employees, it is recommended that two copies of Appendix D are given to each employee. The employees keep one copy and the other copy they sign, acknowledging it was reviewed with them, and management keeps this record for future reference.

Conclusion

Make workers think twice the next time they pick up and use a respirator in the workplace. Eliminate the "grab and go" mentality by educating workers on the difference between mandatory and voluntary respiratory use, take the time to develop a respirator protection program, and provide effective respirator trainings. Results will include protecting the organization's most valuable asset, its employees.

This article originally appeared in the February 2017 issue of Occupational Health & Safety.