Dry Media Dust Collectors vs. Wet Scrubbers: Two Technologies for Combustible Dust Control

At first glance, wet scrubbers may appear to be preferable because they inherently control the combustibility of a dust.

Wet scrubbers and dry media dust collectors are two very different technologies used to capture combustible dusts generated during production processes. These processes include but are not limited to machining, sawing, grinding, buffing, polishing, fettling, brushing, drilling, cutting, and abrasive blasting. Materials that can explode as a dust include most organic materials and many metals. Metals that fall into this category tend to have extreme combustible and explosive properties.

It is important to note that any process producing airborne dust that is not controlled with either wet or dry media dust collection may also pose serious health hazards for your employees. OSHA has established minimum personal exposure limits (PELs) for respirable materials, including finely divided dusts from solids. A facility must make sure that emission levels within the plant stay below these exposure thresholds. They can do this with the correct use of wet or dry dust collection equipment.

What are the primary differences between the two types?

Dry dust collectors: NFPA defines dry dust collectors as cyclone and media collectors such as baghouses and cartridge collectors. This article will focus on high-efficiency cartridge dust collectors, the dry media-type collectors that are most widely used for industrial dust capture. Typically, dust-laden air enters the collector through a baffled inlet and is collected on the filter media. Periodic bursts of compressed air dislodge the dust from the filters and into a hopper. From the hopper, the dust is discharged into a separate storage drum or other container that must be emptied regularly to ensure that dust does not back up into the hopper. (Figure 1)

Today's cartridge dust collectors are available with a wide choice of primary filtration media that can achieve very high efficiencies on very fine particulate, including nano fiber media that combine high performance with long life. Specialized media combine these benefits with additional properties such as fire resistance, static conductivity, and resistance to adhesive materials. In situations where materials have very low OSHA personal exposure limits, a HEPA-grade secondary filter can be added to the system to achieve cleanroom-grade efficiencies. This is important if the exhaust air is returned to the factory.

Wet collectors: Wet collectors include venturi scrubbers and cyclonic or centrifugal-type scrubbers that operate very differently from dry media collectors. Scrubbers filter dust by impingement with water droplets. The smaller the droplet, the more efficient the scrubber. Equipment designs may incorporate spray nozzles, misters, cyclonic action, venturi dispersion, and wet impingement configurations to capture the dust. Many devices use a combination of these techniques. Once captured, the water and dust drop into a settling tank where they are separated by gravity or the dust is skimmed from the surface.

Figure 2 shows a scrubber in which dust-laden air enters tangentially and centrifugal forces move the particulate to the outer wall like a cyclone. The airflow is specially routed to generate an intensive swirl of water that mixes with the dust, causing the particulate to impinge with droplets. Once captured, the particulate will settle to the bottom of the sludge tank.

Maintaining a clean or recycled water supply is an important consideration with scrubbers. The concentration of dust particles in the scrubbing fluid must be kept below 5 percent in order to maintain operating efficiency and, in the case of combustible metals, the amount allowed to accumulate in the discharge vats is prescribed by NFPA.

Wet scrubber filtration efficiencies are highly dependent on the particle size of the dust being collected. For particles less than 10 microns, a venturi scrubber is recommended because it is better designed to capture smaller particles. For particles over 10 microns, a centrifugal collector will save a significant amount of energy.

Wet or Dry: Which to Use?

At first glance, wet scrubbers may appear to be preferable because they inherently control the combustibility of a dust. When combustible dust particles are captured into the scrubbing liquid, they are removed from contact with oxygen and the hazard is controlled. By comparison, dry media collectors are at higher risk of a combustible dust explosion and require more ancillary explosion protection equipment to meet NFPA standards and control the hazards. Furthermore, with some metal dusts (niobium, tantalum, titanium, and zirconium), dry collectors do not comply with NFPA standards.

Aside from these restrictions, dry collectors offer many operational advantages over wet scrubbers. They typically can scale up to very large airflows and heavy dust loads, whereas wet collectors would require multiple systems to handle the same airflows. They offer higher particle removal efficiencies and use less energy to capture fine dust particles. Maintenance and disposal are also simplified, especially when hazardous dusts are involved.

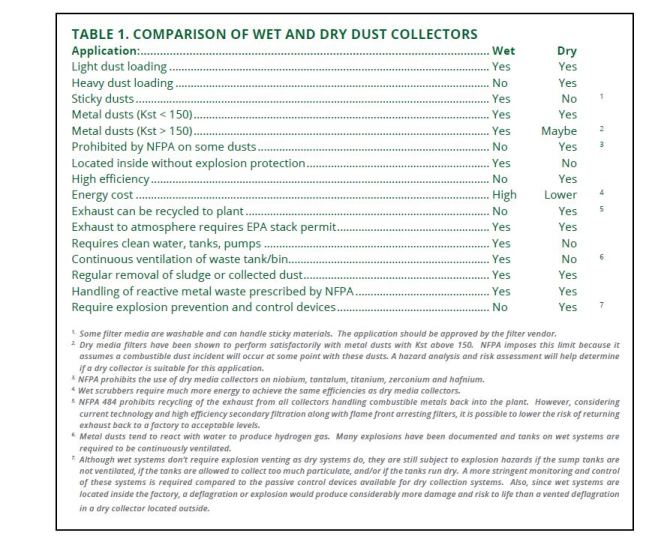

Table 1 provides a general comparison of wet and dry dust collectors and will serve as a useful tool in the selection process.

Sometimes the choice between technologies is not clear. Two types of testing are recommended in these situations: lab testing, which pinpoints physical properties of the dust that affect filter efficiency and performance, and explosibility testing, which determines combustible and explosive properties.

Applying NFPA Standards

When selecting equipment for combustible metal dust applications, NFPA 484: Standard for Combustible Metals is the standard that best addresses wet collection. It covers all metals and alloys in a form capable of combustion or explosion and explains how to determine whether a metal is in a combustible or noncombustible form. It also applies to processing or finishing operations that produce combustible metal powder or dust. Though NFPA 484 is specific to metals, some of its content can and should apply to nonmetal combustible (i.e., organic) dusts.

Hazard analysis is a tool used to improve safety by identifying hazards such as combustible dust deflagration, fire, and explosion hazards. The analysis should start at the design phase of a project and follow the process to the end of its lifespan with periodic reviews and updates.

NFPA 652: Standard on the Fundamentals of Combustible Dust—a new standard released in October 2015—is now the starting point for defining a combustible dust and its hazards. Its purpose is to clarify the relationship between the shared standards and the industry-specific standards such as NFPA 484 for metals, NFPA 664 for wood, NFPA 655 for sulfur, and NFPA 61 for food processing. NFPA 652 introduces a new term, Dust Hazard Analysis or DHA, to differentiate this analysis from the much more complex process hazard analyses required by OSHA for the chemical industry.

Most of the information/requirements in NFPA 652 are carried over from the other standards; however, there is one new requirement with broad-reaching implications. For existing processes handling combustible dusts, the "owner/operator shall schedule and complete DHAs of existing processes and facility compartments within a 3-year period from the effective date of the standard" (October 2015). Currently, OSHA cites facilities that don’t have a hazard analysis, and this new standard will increase enforcement efforts.

The type of dust collector, explosion protection, and duct isolation required for each application will vary, and a DHA should be conducted to determine system requirements. An engineer knowledgeable of the process should perform the assessment with support from the dust collector and protection control suppliers.

In addition to implementing a hazard analysis, NFPA provides numerous provisions on wet and dry collection systems in NFPA 484 Chapter 9. This chapter has a section on specific requirements for wet scrubbers handling combustible metal dusts. It also contains three sections on dry collectors: 1) common requirements for all dry collectors, including cyclones and media collectors; 2) additional requirements for dry media collectors only, and 3) requirements to locate dry-type collectors inside the factory.

The above provisions are too detailed to explain here; however, a white paper is available (registration required) that includes a series of tables that readers can apply to their own situations. These tables summarize the above NFPA 484 requirements for metal dusts and also identify which ones apply and are recommended by the authors for nonmetal dusts. To access the white paper, visit

www.camfilapc.com/wp_wetvsdry.

References

1. National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02169; www.nfpa.org

2. Occupational Safety & Health Administration (OSHA), 200 Constitution Avenue, Washington, DC 20210; www.osha.gov

This article originally appeared in the May 2016 issue of Occupational Health & Safety.