Making the Workplace Safer from the Effects of Lightning

Local monitoring systems provide sufficient time to remove your workers from harm’s way—from the impending lightning strike.

- By Don Krysinski, Todd Vought

- Sep 03, 2015

Annually, lightning strikes cause damage to facilities, disruption of work, injuries, and deaths in some cases. Although we in the United States have made progress in our protecting of structures, there is still room to improve in properly protecting people.

Keep in mind that lightning protection for facilities protects the structure and the electrical systems in the facility, it does not protect people or operations outside of the structure. The purpose of a UL listed lightning protection system is to accept the lightning strike and direct it to earth, causing the least amount of harm possible. This is actually the technique invented by Benjamin Franklin many years ago! The lightning rods (air terminals) you see on the roofs of buildings are there as strike termination devices to accept the strike, which then allows the energy from the lightning to follow a conductor (special wires from the lightning rods) safely to dissipate into the earth. This system works well and as more structures are protected in this way, less damage is being done.

In the United States, there are organizations (including UL and the Lightning Protection Institute) that certify installations of Lightning Protection Systems. The National Fire Protection Association with its NFPA 780 standard defines how to properly protect a structure from the effects of lightning. Outside the structure, there is great concern for the safety of people who, many times, are working in open spaces without protection from a lightning strike.

An important component of protection from the effects of lightning strikes is a Lightning Warning System. If you knew that a lightning-capable storm was building, prior to a lightning strike, you can take preventative measures to help ensure the safety of your field workers.

In the past couple of decades there have been major advances in early detection with storm warning systems that can notify users of impending storms with lightning strike potential. There are two basic types:

Remote monitoring

In this system, warning is sent from a central global storm data collection center. These centers gather their data from satellite images, meteorological radars, and sophisticated weather computing systems. These weather systems predict movement of existing storms toward a facility. Users typically pay a monthly fee and create a warning hierarchy for their facility based about metrics provided in these services.

Local monitoring

In contrast to a centralized weather service-based warning system, the local monitoring approach involves placing monitoring equipment at your site. This gives specific information relative to storms directly (typically monitoring greater than 10 miles in any direction) at your facility. These systems work on electrostatic field buildup to determine different phases of a storm:

1. Gradual charging of the clouds, starting from a normal atmospheric condition.

2. First intracloud (IC) or cloud-ground (CG) lightning strike.

3. Lightning/storm maturity.

4. Storm dissipation.

This is very helpful in establishing preventative actions to protect field personnel as storms build, but just as importantly to know when it is once again safe to work.

The sensing technologies have advanced over the years. The methods of sensing electrostatic field levels can be done in a couple of ways:

- Electromechanical equipment, where an electric motor rotates a set of blades on another set of grounded blades, which creates an electric signal from the electrostatic field. This method is commonly known as the "field mill" technology and has been in use for decades. Although functionally acceptable, it has the drawback of moving parts that could need maintenance from wear and tear under normal use.

- Later technology utilizing solid state components has come onto the market and proved to be a superior method to the field mill and also more accurate. The sensor head is mounted on the top of a building or mast in the center of the area to be monitored. With access to the atmosphere, these devices can sense the electrostatic field buildup and signal a base station about the storm buildup, thus triggering actions prior to a strike occurring. The actions could be to send out text messages, turn on lighted warning systems, initiate audible alarms, etc. Like the field mill, these devices are site specific but are more accurate and maintenance free.

Both of these technologies are site specific and, most importantly, they notify users of lightning before it occurs. Many of the weather monitoring systems base their predictions off of actual strikes, but if you are at the location of the first strike of a storm, it is too late. These local monitoring systems provide sufficient time to remove your workers from harm's way—from the impending lightning strike.

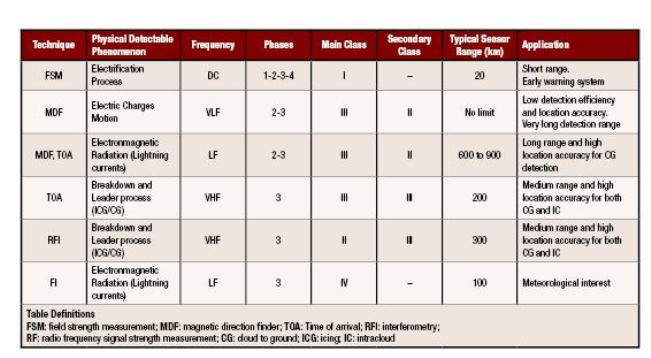

The EN:50536 European Standard

An interesting point about storm warning systems in the United States is that there is not a standard or code they have to adhere to; consequently, there have been different approaches to this very technical problem that have not worked well. In Europe, there is a standard for Thunderstorm Warning Systems. This standard is EN:50536. This standard defines different classes of measurement, with the "Main Class" capable of sensing all phases of a storm buildup, up to and including a mature lightning-producing storm. It is important to note that products that meet these specifications must do so both in functionality and accuracy. The chart below is the properties table from this standard.

Table Definitions

FSM: field strength measurement; MDF: magnetic direction finder; TOA: Time of arrival; RFI: interferometry; RF: radio frequency signal strength measurement; CG: cloud to ground; ICG: icing; IC: intracloud

Protection from lightning should be thought of in a "holistic" approach. There are different methods and technologies that can help different phases of protection:

- Structural protection is protecting the structure and its contents, a necessity that requires the proper equipotential bonding, low earth resistance grounding, and surge protection, in addition to the physical installation of the rooftop lighting rod system. Again, this is all defined by the NFPA 780 standard and can be certified by UL or the Lightning Protection Institute. This is a required protection and safety step that does not address open work areas.

- Storm warning systems are preventative systems that give you adequate warning to remove workers from unsafe conditions. The warning system chosen can be remote or local and have different "intelligence." Combined with your company policies, local storm warning systems can give appropriate warning of impending danger but also provide efficient back to work clearance, which is not a function of policy but of science.

Whatever protection you chose for your facility, it is important to evaluate the options available, keeping in mind the different technologies available and the functions they perform.