Beaconing Sheds Light on the Darkness of Gas Monitor Data

How can you proactively fix a problem when you don't know where it occurred?

- By Dave D. Wagner

- Apr 01, 2017

On the morning of March 23, James Jones reported for work at the local oil refinery the same way he had done routinely for the last 17 years. JJ, as he was known by his co-workers, put on his coveralls, grabbed his hard hat and glasses, picked up his gas monitor, bump tested it, and headed out to inspect the numerous valves he was assigned to check out that day.

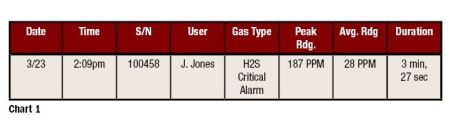

Being fully aware of the gas hazards associated with the refinery, particularly H2S, but having never personally had a bad encounter with gas during his time in the plant, JJ believed that gas accidents only came to those who didn't know what they were doing. That day, and the next few days, seemed to flow normally, but the next week, after JJ docked his monitor for calibration and data download, the refinery safety manager received a data alert based on JJ's monitor that read like this (Chart 1):

When the safety director interviewed JJ, trying to determine the root cause of the alarm, he indicated that he did not recall his instrument alarming that day and did not know exactly where he was at that time.

This scenario occurs routinely when attempting to analyze gas monitor data. The information you have regarding gas exposures and potentially hazardous conditions can be tremendously helpful, but the lack of information that specifically reveals where the conditions existed often leaves you in the dark. How can you proactively fix a problem when you don't know where it occurred?

Gas detection users have long asked for the ability to tie location information to the data in their gas detector. Whether it is for the purpose of tracking hazard locations or simply for helping to find a lost monitor, location data plays a vital role in completing the data picture. The question usually comes in the form of, "Does your gas detector have a GPS?"

Global Positioning is the default technology we think of when we are trying to locate something or someone. GPS can provide pinpoint location data, often with 1-meter accuracy. But GPS is not without serious limitations, particularly when it comes to gas detection. GPS requires the device to have a clear view of the sky to communicate with positioning satellites and thus does not work well indoors. Many outdoor applications around significant structures have limited satellite communication and therefore limit the effectiveness and accuracy of the GPS, as well. It doesn't quite seem right to burden the gas monitor with a GPS receiver when it will only function properly on a part-time basis.

Bluetooth Beacons

Along come beacons. Beacons are small Bluetooth-enabled devices that broadcast location information and other messages programmed into them to any listening Bluetooth device within their transmission range.

We use beaconing commonly without ever realizing it. Beacons are often used in the retail arena to identify when you are in a particular outlet or specific area of a given retail establishment. The beacons will help determine where you are and send advertising messages specific to that area directly to your phone. The phone may hear messages from three or four beacons at the same time, so it uses the received signal strength from each to determine which one it is closest to and which message to accept. Bluetooth beacons are one example of a very clever technology that we are now using every day.

Recently beaconing has come to gas detection. The iAssign™ Beacon from Industrial Scientific is an intrinsically safe, Bluetooth beacon designed to provide an appropriately equipped, Bluetooth-enabled gas detector with location information. Much like the retail application with your phone, the gas detector will listen to the broadcasts from beacons in the area and use those messages, and the received signal strength from the beacons, to determine where it is located and will tag the gas monitor data with a location. Now the data alert from the illustration in Chart 1 can look like this (Chart 2):

What a difference knowing the location makes! You can see clearly now and don't have to rely on the instrument user's memory to determine where the event occurred. You can proactively investigate the area, determine the root cause of the exposure, and eliminate the hazard before a potentially tragic incident occurs. The iAssign Beacons can be deployed and function anywhere—inside or out, hazardous location or safe zone. If access to line power is not available, it doesn't matter. The beacons are low cost, rated for any Class I area, are weather resistant, and operate up to four years on two AA batteries. They can provide location accuracy down to 1 meter, depending on the settings and number of beacons deployed, without the need for a GPS receiver or a complex triangulation algorithm and other costly wireless infrastructure.

Using Beacons for Access Control

Location tagging isn't the only function the beacons provide. Beacons can be used in conjunction with the gas detector to control access to a particular area. Based on settings and access level of the user assigned to the instrument, when in proximity of a beacon marking a designated area, the beacon can trigger the instrument to alarm and display a message to its user that they are in an area with "ACCESS RESTRICTED." They can also be used to activate or deactivate particular instrument functions, control settings, or send a message that other particular safety equipment is required to be used in a given area.

Data that tells you the "what" and the "when" without telling you the "where" leaves you wandering in the dark and unable to determine the why of any event. Beaconing shines light on your data and allows you to recognize the full value of the data that your gas monitoring program can provide.

About the Author

Dave D. Wagner is the Director of Applications Engineering & Product Knowledge at Industrial Scientific Corporation. He can be reached at [email protected].