GHS Training: Passing Deadlines Don't Mean the Work is Over

Employers can see that employee training, while part of the first and final deadlines in OSHA's GHS transition period, is actually an ongoing obligation.

- By Glenn D. Trout

- Jul 01, 2016

OSHA's final compliance deadline for the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) has passed. OSHA now expects all companies covered by its Hazard Communication Standard (HazCom) to be in full compliance with the changes brought on by its adoption of GHS—the United Nations' model hazard communication system. This means companies should have fully updated libraries of SDSs and labels on containers. In addition, companies should have updated chemical inventory lists, written plans, and employee training information.

Just as it was necessary before GHS adoption, employers must continue to ensure employees are trained to work safely with the hazardous chemicals present in their in their work environment. This means keeping employees versed on the new 16-section strictly ordered SDS format, the six core elements of a shipped container label, any newly identified physical or health hazards associated with chemicals entering the workplace—an occurrence brought on by the new way in which chemical suppliers are required to classify their products—and how to use the company's HazCom program information to stay safe.

A Wakeup Call

The first GHS deadline focused on employee training and laid the groundwork for the GHS deadlines because workers needed to understand the new SDS and label formats in preparation for their entry in their work environment. For companies that provided regular, comprehensive employee safety training programs, meeting the GHS training deadline wasn't a major cause for concern. However, the alignment with GHS exposed the unsettling reality that many employees had never received adequate HazCom training in the first place or had been trained so long ago that they hadn’t retained the information and now lacked the basic understanding necessary to put the GHS modifications into context. For these companies, training had to not only include information about GHS, but also a refresher on OSHA HazCom basics.

These findings, along with HazCom continuing to rank second on OSHA's most frequently cited standards list, demonstrate why the agency put such emphasis on employee training when aligning its HazCom Standard to the GHS. And while GHS training may have come at a great cost—more than $95 million, according to the agency’s estimate in the final rule—the changes helped update a standard that had been largely unchanged since its establishment in 1983. The harmonization of information resulting from adoption could be seen as a way to simplify training efforts and save employers' time after the GHS transition period. OSHA's adoption of GHS provided a wakeup call for the millions of companies across the United States covered by the rule that they needed to do a better job with HazCom training.

Employers should see the GHS deadlines not simply as compliance dates that have passed, but as effective dates requiring them to be compliant with specific provisions of the modified rule from those dates forward. In this way, employers can see that employee training, while part of the first and final deadlines in OSHA's GHS transition period, is actually an ongoing obligation.

Right to Know vs. Right to Understand

A critical aspect of GHS adoption was its ability to improve employee comprehension of critical chemical safety information. When OSHA published its HazCom Standard in 1983, the concept of an employee's right to know of the hazards they work with helped shape the safety culture that is currently enforced today. The changes to the HazCom Standard under GHS took that concept one step further by introducing the idea that workers not only had the right to know about hazards in their work environment, but also the right to understand them. Considering the overall changes brought about by the GHS alignment, this subtle word adjustment is easily overlooked. However, it's a critical clue that signals how OSHA expects employees to be trained.

The pre-GHS employee right to know concept translated most literally into giving workers access to information so they know what hazards exist. This sharing of information had been facilitated through safety data sheets and labels that indicated any dangers. However, a study conducted by OSHA and the University of Maryland found that many employees didn't understand approximately one-third of the safety and health information listed on these documents.

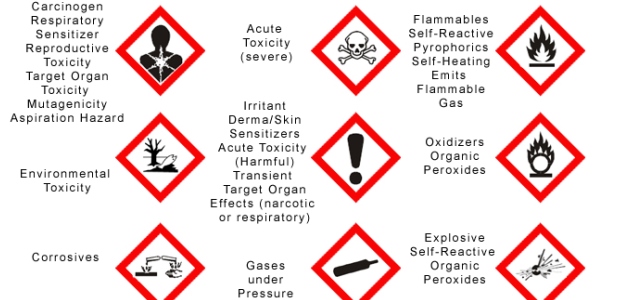

GHS helps solve this issue with a more standardized approach to hazard communication on SDSs and labels. The harmonized and easy-to-find information presented on both communication pieces—with elements such as pictograms that help convey hazards via easy-to-understand images and content—allow employees to more quickly identify the hazards associated with the chemicals in their work environment. By instituting a simplified approach to communicating hazard information, OSHA is saying that it is not enough to just provide hazard information access, but to ensure workers understand and comprehend that information more than they may have in the past.

Furthermore, OSHA’s right to understand concept reiterates the agency's policy that employee training must be presented in a manner that employees can comprehend and retain. In practical terms, this means that an employer must instruct its employees using both a language and vocabulary that the employees can understand. As an example, if an employee does not speak English, training must be provided in the language that the employee can understand. If employee training on the GHS changes hasn't yet taken place, then this is a requirement that needs to occur immediately. Fortunately, there are a multitude of options, including web-based on-demand training, that offer courses in multiple languages to aid employers in this need.

The Right Kind of Training

While OSHA doesn't have specific instructions for how the training occurs, it does state that the training be effective. The agency urges that employees must be able to apply any training they receive to the work and tasks they complete daily. With this understanding, an effective HazCom training program can be broken down into two components.

The first component should focus on a basic understanding of the HazCom Standard. Depending on the employees' level of training, this can either be a refresher course to better understand the GHS changes or a deep dive into the standard if previous courses hadn’t adequately covered the topic. It is up to the employer to determine the level of HazCom training each individual employee requires.

The second component takes HazCom training a step further by focusing more on the individual hazards employees face. Depending on the hazardous chemicals present in the facility, this training can either concentrate on a specific chemical and its hazards or a category of similar hazards for different chemicals; the key here is that it provides employees with a deeper understanding of the dangers and emergency situations they may face.

Employees also must continue to receive training on some pre-GHS HazCom elements, especially if both MSDSs and SDSs still exist in the chemical inventory. Even though the final GHS changes have gone into effect, many facilities still have MSDSs in their libraries, especially those using a chemical from a manufacturer that has gone out of business, didn't receive an updated SDSs from their upstream suppliers due to delays in authoring the new documents, or have not yet received the next product shipment since the updated SDS was created.

Another instance where employees might still be exposed to MSDSs is when archiving chemical information according to OSHA's "Access to Employee Exposure and Medical Records" standard, which instructs employers to keep a record of what chemicals were used when and where for at least 30 years. Employees tasked with keeping these records, whether done through the keeping of a log, inventory list, or archiving the actual MSDSs, need to know the documents exist to compile this information.

In general, it remains the employer's responsibility to provide training on these formats as long as the pre-GHS formatted documents are still being circulated.

Moving the Needle

While not an OSHA requirement, training programs are the most effective when measured by regular evaluations that indicate when retraining is needed. For companies looking for a better method to track employee training, a web-based EHS training management solution centralizes training programs to give safety professionals better visibility of course obligations and deadlines. This software helps create organizational-wide workflows that align with individual employee training needs and indicate any new curriculum requirements that updated regulations—such as GHS—often create.

A good training management software solution holds individual employees more accountable for meeting training deadlines with automatic email notifications when sessions are coming up or past due. With a better training management system in place, safety professionals have greater control and visibility to report on the overall training needs and results.

Overall, these solutions turn employee training programs into a competitive advantage with tools that help employers more efficiently drive productivity and reduce any operational risk that comes from missed deadlines or outdated certifications.

A New Normal

It's important to reiterate that HazCom training is not a one-and-done requirement of GHS alignment. Employers must continue to train new employees on the HazCom Standard and deploy regular retraining to existing workers as needed. While the GHS changes may have caused a disruption among some employers, it’s important to recognize its immense benefits to employee safety.

GHS is also just the beginning; OSHA already has indicated that it plans to introduce additional changes in the coming years as part of the agency's continued efforts to create and sustain safer workplaces. Regulatory requirements will continue to change, and it is the employers' responsibility to modify training programs to evolve with them. As a result, employers should look at the GHS as an opportunity to establish a more effective training program to deploy and manage future training needs with any additional changes to come.

About the Author

Glenn Trout is the president and CEO of VelocityEHS, a leading cloud EHS software company dedicated to helping its customers reach their EHS and sustainability goals faster through a simple and intuitive platform that is more affordable, faster to implement, and aims to provide the best user experience. For more information visit www.VelocityEHS.com or call 888-362-2007.