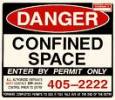

Confined Space Entry Past, Present, and Future: Where Do We Go From Here?

Remember: The safest entry is no entry at all!

It has been quite a while since I last wrote on this topic for Occupational Health & Safety. Things continue to change, so it makes good sense to take a fresh look.

The purpose of this article is to review the various reasons that one may have for entering confined spaces, and then to offer a variety of alternative technologies and approaches for avoiding entry in the future. While it is unlikely all organizations can eliminate the need for confined space entry, it is very likely many organizations can at least reduce the frequency of entry. As things continue to change, however, more opportunities are arising.

Definitions

Because I must, let's begin by reviewing the definition of a confined space. A confined space is "A space that is large enough and configured in such a way that an employee can enter and perform assigned work. It also has limited or restricted means of entry or exit (e.g., tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces), and is not designed for continuous employee occupancy."

The implication of the definition is that entering into a confined space where hazards are present has greater risk because of the work conditions. With that as a basis for our discussion, let's proceed.

Reasons for Entry

The reasons why confined space entry may be required really have not changed much in the past decade. Some of these might include:

- Product removal: A site's workers may have to remove a product from a tank, silo, vault, or similar space for reprocessing, or there may be a need to change out production to a different product.

- Spills: Spills or releases may flow to vaults, sewers, catch basins, pits, or similar locations.

- Maintenance: Confined spaces of all types may require entry in order to perform repairs, complete inspections (regulatory, post-incident, and or good engineering practices), provide for new installations, etc.

- Cleaning: Cleaning may be required for decommissioning of equipment, as a follow-up to product removal or spills, or in preparation for maintenance activities.

Why to Not Enter (In other words, Why Should We Consider Alternative Technologies and Approaches)

Despite the many reasons why confined space entry may be required, there are overriding reasons why to not enter. Consider, for example:

- Chemical exposure: Many entries are into spaces containing, or formerly containing, hazardous chemicals. Obviously, work in an area with reduced natural ventilation increases the potential for exposure through inhalation, and because of the nature of the space, physical contact may be more likely, as well.

- Physical hazards: Entry into confined spaces can subject the entrants to entrapment, engulfment, mechanical hazards, heat, cold, and a host of other hazards.

- Equipment requirements: Entries require the use of specialized equipment, including extraction devices and other rescue equipment. Much of this specialized equipment is of no use for other workplace activities, which necessarily adds cost burden to the operations.

- Personnel requirements: A safely performed entry will require at least three people, and possibly more. Other personnel, including those assigned to rescue services, will necessarily be on standby. The overall commitment of employee resources for these activities can be quite significant.

What Are My Alternatives?

So, you ask, if I have tasks to perform and yet have all of these risks and reasons not to enter, what are my alternatives? Let's consider several specialized pieces of equipment (many of which have been improved), as well as common and not-so-common techniques.

Product/material handling equipment: high-power vacuum systems

In order to remove material from a confined space without entry, one option might be a high-power vacuum system. These systems can be truck- or trailer-mounted, can achieve air flows of 500 to 7,000 cfm (or more), and are capable of establishing 15 to 30 inches of Hg vacuum. The units can be equipped with suction lines of up to 8 inches in diameter, allowing for removal of even large debris, and will move material up to 1,000 feet laterally (less vertically). They can be operated in wet or dry mode and may be further equipped with HEPA filtration. Other special options include explosion vents, special interior coatings, internal wash down systems, swing out cyclone collection, and specially designed drop-out collection containers. With a high-power vacuum system, you can move abrasives, brick, catalysts, cement, chemicals, oil, sludge/slurries, clay, coke, and virtually any other debris from virtually any confined space without the need to enter the space.

Specialized cleaning equipment

There are several options available for cleaning without entry. These can include water jet cleaning, abrasive blasting, and chemical cleaning.

- Water jet cleaning. The typical water jet system (also known as hydro-blasting equipment), depending upon the pump and configuration, can produce a water jet of 1,000 to 100,000 psi (or more) at volumes of 1 to 100 gpm (or less). This pressure can literally cut steel or concrete and certainly, with the minimal volumes of water used, can be a creative cleaning solution. Water jet systems are in extensive use within a variety of industries, including pharmaceutical, chemical, petroleum, food processing, and transportation. In addition to "shotgun" cleaning wands, the units can be equipped with lances (for cleaning long portions of piping) and with cleaning heads that can operate at variable speeds and can further clean three dimensionally over 360 degrees of coverage. Specialized applications include telescoping booms, retractable units for cleaning railcars or horizontal tanks, and skid-mounted units for cleaning large-diameter pipes. Water jet systems even can be included in a new engineering design to automate or semi-automate the cleaning process.

- Abrasive blasting. When someone mentions abrasive blasting, most people think of sandblasting. There are, however, several other options, the most intriguing being CO2 pellet blasting. The obvious advantage of CO2 as a cleaning medium is that during the blasting process the "abrasive material" sublimes, leaving only the residue of the material previously in the space, now ready for easy removal.

- Chemical cleaning. A number of companies specialize in chemical cleaning, using caustic or solvent cleaning materials to clean vessels, tanks, and other containers. Some of the cleaning materials are "off the shelf," but experienced companies can develop customized cleaning solutions, as well. Another chemical cleaning method is simple neutralization, which can be used quite effectively with acids and bases.

Repair Equipment

The increase in the use and availability of specialized robotics has created a wide variety of opportunities for avoiding entry into confined spaces. Mechanical cutting heads, remote welding capabilities, and guidelines combined with cameras allow for safer methods for repair and maintenance within confined spaces.

Inspection of Equipment

While IR and X-ray inspection or testing methods have been in use for many years, increased sensitivity and improved methods are creating rapid advancements in the use of these techniques as opposed to direct visual inspection. An added bonus, of course, is that these types of inspection actually yield more accurate results, allowing for better decision-making.

Another inspection technique that continues to advance is the use of opto-electronic equipment to inspect ducts, pipelines, drains, and sewers from 6 inches to 80 inches in diameter. This equipment allows for inspection of live water and live gas lines, which eliminates the need for downtime; it is joystick controlled and resembles a technical version of a modern video game.

Non-Entry by Design

Regardless of whether some of the specialized equipment described above is used or an alternative approach is taken, the best time to consider the prevention of the need to enter confined spaces is at the design stage. Consideration of approaches such as: removable agitators; fixed cleaning systems; oversized inspection plates/windows; and/or clean-outs (such as bottom take offs) can simplify cleaning, repair, and inspection and eliminate or at least minimize the need for confined space entry. More options are developed every year. Talk to providers and stay abreast of opportunities.

Safety Considerations

Every modified approach, of course, has the potential to create new hazards that did not previously exist. High-pressure water blasting introduces the possibility of liquid injection injuries; high-power vacuum systems introduce new sources of physical injury and noise; solvent cleaning processes may create flammable atmospheres, while other cleaning agents present new chemical hazards; and CO2 blasting probably will result in oxygen-deficient atmospheres. A process safety review should be performed whenever changes in approach occur.

Summary

Specialized equipment, changes to procedures, non-entry by design, and customized/creative approaches can eliminate or reduce the frequency of the need to enter confined spaces. Plan now for later, and be creative. Just because it has always been done this way does not mean it must be done this way in the future. Consider the new safety hazards that may be created, but always remember: The safest entry is no entry at all!

This article originally appeared in the November 2012 issue of Occupational Health & Safety.

About the Author

Robert E. Brown Jr., CIH, CSP, is Director of EHS for G&G Risk Management Consultants, Inc. (www.ggrmc.com) in Antioch, Calif. He has more than 20 years' experience in developing and implementing creative and effective compliance solutions.