Radiation Sources in Natural Gas Well Activities

More attention and monitoring of occupational radiation exposure in the natural gas industry are warranted.

- By Gayle Nicoll

- Oct 01, 2012

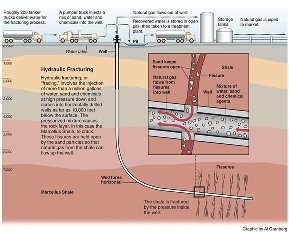

The boom in the natural gas industry across the nation, made possible by recent advances in hydraulic fracturing ("fracking") methodology, has resulted in increased concern for public and environmental safety. This, in turn, has resulted in a series of recommendations for minimizing the risk to the public and the environment (Secretary of Energy, 2011). The natural gas industry has responded to environmental concerns by cleaning and recycling frack water, which can take the form of settling bins, filters, and reverse osmosis devices, among other practices.

The very practices that are meant to minimize the environmental impact of fracking on the surrounding area may have significant negative impacts on the workers employed at these facilities. The risk is from exposure to increased concentrations of ionizing radiation, which is naturally present in the ground in the forms of radium, thorium, uranium, lead, and/or radon (Horn, 2009; EPA, 2011). Until recently, the occupational risk of exposure to radioactive material has been largely ignored. The secretary of Energy's 2009 final report mentioned the potential for radioactive isotopes only once in the 23-page report. However, the study by Horn (2009) and subsequent investigations by The New York Times (Urbina, 2011) have resulted in more attention to the matter by the Department of Energy (DOE) (McMahon, 2011).

Sources of Radiation

The Earth itself is radioactive, and the ground contains a variety of radioactive isotopes. Coincidentally, deposits of natural gas tend to have higher concentrations of radioisotopes, and this fact has been used by geologists to locate natural gas deposits (EPA, 2011). This naturally occurring radioactive material (NORM) is typically composed of one or more of the following elements:

- Uranium and its decay products (including Radon)

- Thorium and its decay products

- Radium and its decay products

- Lead-210

The metals usually do not exist in their free metallic form but are found in the geology as salts. Uranium salts are generally not soluble in water, but radium salts are. Thus, the water existing within the rock formations, called formation water, has high concentrations of both salts -– hence the term "brine water" -– and radioactivity.

When a well is installed, radioactivity can come to the surface in several ways:

- Drilling fluid. During the drilling process, the rock cuttings must be removed so drilling can continue. To this end, drilling fluid is used to bring the rock cuttings to the surface. The drilling fluid can be a liquid, a gas, or a combination of the two. Drill fluid itself is usually a mud-like substance that contains the rock cuttings, which may have radioactive solids, and formation water, which likely has radioactive salts (Resnikoff, et al., 2010).

- Fracking. Anywhere from 10 to 40 percent of the water used in fracking comes back up the well (Urbina, 2011) carrying formation water and concentrations of salts that dissolve in the frack water, which includes NORM.

- Production. Formation water, which contains high concentrations of salts and radioactivity, is brought to the surface along with the extracted gas and oil. Radon gas is also extracted along with the natural gas.

Radioactive Concentration

The natural radiation of the Earth, generally not a cause for concern, is called background radiation. However, any process that concentrates natural radiation produces technologically enhanced NORM, or TENORM -– technologically enhanced naturally occurring radioactive material. TENORM poses a higher risk to people due to higher concentrations of radioactive materials. The work involved in drilling and maintaining a well produces TENORM, such as:

- Scale. Salts have a specific solubility in water. Once that solubility level is reached, no more of that salt will dissolve in the water. Excess salt – including radioactive salts – will precipitate out on nearby solid surfaces, including the well head and casing. Other areas that can have radioactive scale deposits include the water lines associated with separators, heater treaters, and gas dehydrators.

- Recycling water. Radioactive salts are not easily filtered out of water. Each time the water is sent down the well, the concentration of radioactivity in the water increases. In addition, if chemical scale inhibitors are used, the concentration of radioactivity remains in the water. Companies typically use recycled water in many different ways in an effort to be environmentally conscious and efficient. For example, companies routinely spray recycled water on unpaved roads several times a day as a dust suppressant, which could expose workers and the environment to increased radiation levels. In the winter, recycled water can also be sprayed on roadways to de-ice the roads, having a similar result.

- Separation pits. Separation pits are used to divide the solids, including drill cuttings, and from the liquids – formation water and drill fluid. As the solids settle out, they may contain increased concentrations of radioactive material. The liquids may also have increased radioactive concentrations.

- Shale shakers. A similar concept to the separation pits, shale shakers are used to separate solid and liquid wastes. Both the liquid and solids may contain elevated radioactivity.

- Filters. Often cloth or bag filters are employed in the process of cleaning the water before reuse. The fine sediment that collects in the screen or filter may contain elevated radioactivity.

- Sludge. Sludge is composed of dissolved (potentially radioactive) salts that precipitate from produced water as its temperature and pressure change.

- Equipment. As a result of work processes that spread radioactivity over the work site, the equipment can become contaminated with radiation. Gas processing equipment with the highest radiation levels includes reflux pumps, propane pumps and tanks, and more (EPA, 2011).

Radioactive Levels and Regulations

Many studies have been done across the United States to determine the concentration of NORM within specific natural gas formations, in Pennsylvania (Pennsylvania Geology, 2008), Arkansas (Arthur et al., 2008), and Louisiana (STRONGER, 2011). Some of these same studies have reported radioactivity levels for NORM at natural gas wells. However, other studies report widely different values for radioactivity at wells in the United States based on geographic location (EPA, 2011), radioisotopes studied (Rahon, 2010), and processes studied (Smith et al., 1996).

Many studies have been done across the United States to determine the concentration of NORM within specific natural gas formations, in Pennsylvania (Pennsylvania Geology, 2008), Arkansas (Arthur et al., 2008), and Louisiana (STRONGER, 2011). Some of these same studies have reported radioactivity levels for NORM at natural gas wells. However, other studies report widely different values for radioactivity at wells in the United States based on geographic location (EPA, 2011), radioisotopes studied (Rahon, 2010), and processes studied (Smith et al., 1996).

The EPA ranges are reported here, although the EPA values are only for wastes and do not include filters, sludges, or other items. In fact, no comprehensive study of the radioactivity levels at various parts of a natural gas well pad have been published.

To put the numbers presented in the table below into context, they should be compared to regulatory limits. OSHA's regulations for radiation exposure are contained in 29 CFR 1910.1096. OSHA requires that occupational workers over the age of 18 not be exposed to a whole-body dose of more than 1.25 rems per calendar quarter (three months). Furthermore, if measured radiation levels are more than 25 percent of regulated levels -– that is, 0.312 rem (312 mrem) per calendar quarter -– the employer is required to supply radiation monitoring equipment to employees, which can include film badges, electronic dosimetry meters and radiation survey meters.

| Substance |

Radioactivity Range |

| Produced Water |

0.1-9,000 pCi/L |

| Pipe & Tank Scale |

0.24-100,000 pCi/L |

A straightforward comparison between the numbers in the table above and the OSHA values is not possible, since radioactivity is reported in units of Curies (Ci), while radiation exposure is reported in rem. However, a calculation can be performed on the activity values in the table, knowing that the main source of radiation is from Radium-226. To be able to perform the calculation, a few assumptions must be made:

- Assume an exposure distance of 1 foot, which is the standard distance to perform a radiation survey.

- Use the highest activity in the table (100,000 pCi/g)

- Assume 1 kilogram (kg) of scale. One gram, the value listed in the table above, is a relatively small quantity, and larger masses are likely at these sites.

Given these stipulations, a worker could potentially be exposed to 0.69 mrem/hour of radioactivity from Radium-226 and its daughter isotopes in the form of gamma radiation. Assuming an eight-hour workday, this would equate to 331 mrem/quarter, which is above the level at which OSHA requires radiation monitoring.

Of course, this is a back-of-the-envelope calculation, based on a set of assumptions. In reality, a worker is not going to spend the entire workday within one foot of the wellhead. However, the worker will be moving around the work site, potentially being exposed to radiation from scale, formation water, recycled water, equipment dust, and sludge. The geographical location will also affect the amount of TENORM at the site. For example, the Horn (2009) study reported higher radioactivity levels in New York (123,000 pCi/L) than the EPA (2011) range.

Historically, sites have not monitored for radiation (Horn, 2009), so natural gas companies do not know whether they are in violation of OSHA regulations and workers do not know whether they are at risk. Therefore, more attention and monitoring of occupational radiation exposure in the natural gas industry are warranted. NIOSH has acknowledged that an occupational risk from NORM may exist in the industry and is conducting further research (Esswein, et al., 2012).

Occupational Exposure

Occupational exposure to radiation in the natural gas industry can come from a variety of sources, several of which have already been discussed in this article. More generally speaking, exposure can take the following forms:

- External exposure. External exposure is radiation that enters the human body through the skin. Externally, the most dangerous form of radioactivity is gamma waves. Radon and Radium are gamma-emitters. External exposure may come from any portion of the well pad, including the roads, equipment, sludge, process water, and pipes.

- Internal exposure. Internal exposure is radiation that enters the human body through an opening, such as the mouth or lungs. Internally, the most dangerous form of radioactivity is alpha particles. Radon and Radium are also alpha-emitters. Intake of radioactivity into the human body can come from any of the following activities on site: breathing radon gas or dusts contaminated with radiation, smoking, eating, drinking, chewing gum, chewing tobacco, and contact of radioactive materials with open wounds.

Occupational Monitoring and Protection

Radiation monitoring of occupational exposure can be performed on the whole work area as well as on individual workers. Note that both methods measure external exposure only.

An assessment of the work area involves a comprehensive survey of all potentially radioactive materials using a hand-held radiation survey meter, such as a Geiger-Müller (GM) tube. A map of the facility is used to record locations of measurements. Measurements are generally made 1 foot from the material being surveyed, unless workers routinely approach the material at a closer distance. Surveys are conducted during a work shift with a worker so normally inaccessible items, such as filter bags, also can be surveyed. For facility owners, surveys should be conducted once a week.

Individual worker exposure can be monitored in real time using an electronic personal dosimeter. A worker wears the dosimeter on the torso for the duration of the work day, and the final reading is recorded at the end of the day. Electronic dosimeters are usually used in areas where high radiation is already known to exist or for one-time occupational exposure measurements. More than one dosimeter is used at each facility in order to obtain representative exposures for different work tasks.

Alternatively, individual worker exposure can be monitored using film badges worn on the torso each work day for an entire month and then sent to a processing facility to read the results. Note that film badges do not report results in real time. Film badges are used by facility owners in areas where elevated radiation exposure is a possibility.

Typical occupational radiation protection involves the following measures:

- OSHA-regulated signs for areas with potentially elevated radiation exposure

- Periodic radiation surveys

- Safety training

- Personal protective equipment: OSHA Level D, including gloves and safety glasses. (For high-level radiation exposure, more-protective PPE may be warranted.)

- Occupational monitoring using film badges

- Designated "clean" area for eating and storage of personal items

References

1. Arthur, J. D.; Bohm, B.; Coughlin, B. J.; Layne, M. (2008). Hydraulic Fracturing Considerations for Natural Gas Wells of the Fayetteville Shale. ALL Consulting, Available at http://www.aogc.state.ar.us/all%20fayettevillefrac%20final.pdf.

2. Environmental Protection Agency (EPA). (2011). Oil and Gas Production Wastes. July 8. Available at http://www.epa.gov/rpdweb00/tenorm/oilandgas.html#residentsoffice.

3. Esswein, E. Kiefer, M.; Snawder, J.; Breitenstein, M. (2012). Worker Exposure to Crystalline Silica During Hydraulic Fracturing. NIOSH Science Blog. Centers for Disease Control and Prevention, May 23. Available at http://blogs.cdc.gov/niosh-science-blog/2012/05/silica-fracking/.

4. Horn, E. G. (2009). Letter to Bradley Field, Director; Division of Mineral Resources; New York State Department of Environmental Conservation. Marcellus Shale Potential Public Health Concerns, State of New York Department of Health, July 21. Available at http://treichlerlawoffice.com/radiation/nysdoh_marcellus_concerns_090721.pdf.

5. McMahon, J. (2011). Fracking Radiation Targeted by DOE, GE. Forbes. Aug. 3. Available at http://www.forbes.com/sites/jeffmcmahon/2011/08/03/fracking-radiation-targeted-by-doe-ge/.

6. Pennsylvania Geology. (2008). PA Bureau of Topographic and Geologic Survey, 38(1), Harper, Spring.

7. Rahon, T. E. (2010). Radiological Survey Report. Marcellus Shale Drilling Cuttings from Tioga and Bradford Counties, PA. and New England Waste Services of N.Y., Inc. Landfill Sites in Chemung, NY, Campbell NY, Angelica NY. CoPhysics Corporation, April. Available at http://treichlerlawoffice.com/radiation/CoPhysicsApr10.pdf.

8. Resnikoff, M.; Alexandrova, E.; Travers, J. (2010). Radioactivity in Marcellus Shale. Report prepared for residents for the Preservation of Lowman and Chemung, Radioactive Waste Management Associates, May 19. Available at http://www.rwma.com/Marcellus%20Shale%20Report%205-18-2010.pdf.

9. Secretary of Energy. (2011). Shale Gas Production Subcommittee Second Ninety Day Report, US Department of Energy, Nov. 18. Available at http://www.shalegas.energy.gov/resources/111811_final_report.pdf.

10. Smith, K.P.; Blunt, D. L.; Williams, G. P.; Tebes, C. L. (1996). Radiological Dose Assessment Related to Management of Naturally Occurring Radioactive Materials Generated by the Petroleum Industry. Environmental Assessment Division, Argonne National Laboratory, September. Available at http://www.ead.anl.gov/pub/doc/anlead2.pdf.

11. State Review of Oil & Natural Gas Environmental Regulations (STRONGER). (2011). Louisiana Hydraulic Fracturing State Review. Louisiana Department of Natural Resources, Office of Conservation, March. Available at http://www.shalegas.energy.gov/resources/071311_stronger__louisiana_hfreview.pdf.

12. Urbina, I. (2011). Regulation Lax as Gas Wells’ Tainted Water Hits Rivers. The New York Times. Feb. 26, 2011. Available at http://www.nytimes.com/2011/02/27/us/27gas.html?_r=1&pagewanted=all.

This article originally appeared in the October 2012 issue of Occupational Health & Safety.