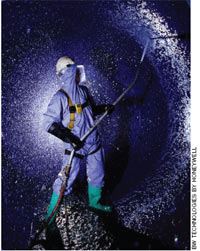

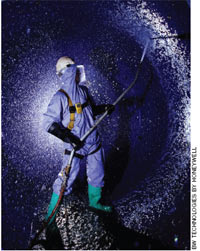

Marine Vapor Dangers

When confined space entry is added to the mix of transporting explosive and toxic cargo, it makes for a potentially dangerous combination.

- By Shane McEwan

- Nov 01, 2008

When it comes to hauling cargo such as liquefied natural gas (LNG), oil, or BTEX (benzene, toluene, ethylbenzene, xylenes), safety personnel must be made aware of all safety concerns, especially during transportation at sea. Marine personnel can potentially be exposed to dangers that include oxygen deficiency or enrichment, explosive gases, and toxic effects from cargo and maintenance chemicals.

When it comes to hauling cargo such as liquefied natural gas (LNG), oil, or BTEX (benzene, toluene, ethylbenzene, xylenes), safety personnel must be made aware of all safety concerns, especially during transportation at sea. Marine personnel can potentially be exposed to dangers that include oxygen deficiency or enrichment, explosive gases, and toxic effects from cargo and maintenance chemicals.

The IBC code (international code for the construction and equipment of ships carrying dangerous chemicals in bulk) of the International Marine Organization (IMO) states that ships carrying toxic or flammable product shall be equipped with at least two instruments designed to detect for the specific vapors in question.Tank inspections are necessary tasks onboard and also classified as confined spaces, marine vessels, because there is a constant concern for corrosion. These spaces can include boilers, pressure vessels, cargo holds, ballast tanks, double bottoms, double hull spaces, fuel oil, lube oil, sewage tanks, compressor rooms, pump rooms, cofferdams, void spaces, duct keels, inter barrier spaces, and engine crankcases.

Known Hazards

Common hazards in typical confined space entry are oxygen deficiency or enrichment and toxic and combustible gases. Hazards specific to the marine industry come from the toxic and combustible effects from cargo that is hauled and from the inert atmospheres that are created to control the explosive nature of the cargo.

Confined space entry onboard a marine vessel can be extremely dangerous. Conditions can change very rapidly as the ship constantly moves in the sea. Entry and exit holes may be as small as 2.5 feet by 2 feet. Special Teflon® or Teflon-lined tubing should be used for sampling so target gases are not absorbed. Cargo areas that are inerted or contain toxic cargo may leak into adjacent spaces that need to be entered.

Stratification

How to obtain a sample from the confined space atmosphere and determining whether or not it is safe to enter are key considerations. All gases have a vapor density; in comparison to normal air, some gases are heavier, lighter, or have a comparable density. Based on vapor density, gases in a confined space will stratify. For example:

Methane is lighter than air and tends to collect in pockets at the top of a space.

Oxygen is a component of air and can be found at all levels.

Carbon monoxide is relatively close to the density of air and can be encountered at all levels.

Hydrogen sulfide is heavier than air and tends to collect at the bottom.

The gases from most petroleum liquids are heavier than air (propane, butane, hexane) and will collect at the bottom.

Obtaining a representative sample at various levels prior to entry is important. Sampling at the ceiling, middle, and bottom of a confined space must be done before an “all clear” for entry can be declared.

Inert atmospheres

During transport of highly flammable cargo (LNG, liquefied petroleum gas [LPG], and certain chemicals [n butyl ether, diethyl ether, propylene oxide, vinyl ethyl ether]), inert gases such as nitrogen and carbon dioxide are introduced into holds to remove the possibility of combustion. The primary hazard associated with inert gas is oxygen deficiency, resulting in asphyxiation.

Oil tankers typically use inert gas produced by combustion, either in a steam raising boiler or in a separate inert gas generator (flue gas). Asphyxiation from the deficiency of oxygen is a concern, but there are also toxic concerns from this type of inert gas. Flue gas typically contains approximately 200 ppm of mixed nitrogen oxides. The majority is nitric oxide (NO). OSHA lists the Time Weighted Average (TWA) of NO as 25 ppm.

If the fuel has a high sulfur content, then the flue gas can contain from 2 to 50 ppm of SO2 after the inert gas has gone through water scrubbers. ACGIH lists the TWA as 2 ppm and the short term exposure limit (STEL) as 5 ppm.

Carbon monoxide is normally present in flue gas but is typically at very low levels of only a few ppm. If there are abnormal combustion conditions or a slow running condition, then CO levels can rise to over 200 PPM. NIOSH lists the TWA as 35 ppm and the STEL as 200.

Entering Confined Spaces Adjacent to Inerted Tanks or Loaded Tanks

Leaks can travel from the area inerted,mechanism inerting, or from loaded cargo areas into an adjacent space that is to be entered. In order to be able to identify all hazards in the space to be entered, the following should be known:

• Identify the latest content of the spaces to be entered and the content in spaces adjacent to them.

• A data sheet for the last cargo should be presented (gas carriers).

• A data sheet for the previous three cargos should be presented (chemical tankers).

Flammable Measurement (Explosimeters)

Most commonly used combustible sensors detect gas by catalytically oxidizing or burning the gas on an active bead or pellistor located within the sensor. While there are numerous variations, the underlying detection principle has not changed for the better part of a century.

Catalytic-bead sensors require at least 8 - 10% oxygen by volume to detect accurately. A combustible sensor in a 100% gas or vapor environment will produce a reading of 0% LEL. This is the reason that testing protocols for evaluating confined spaces specify measuring oxygen first and then combustible gases and vapors. Because the inert atmosphere has less oxygen than what is required for catalytic bead type detectors, other devices should be used to measure combustible levels in inert atmospheres.

The following gas detector types do not require oxygen for the flammable measurement and are the preferred method in inert atmospheres: infrared (IR) instruments, non-catalytic heated filament gas indicators, and inferometer.

Ambient Dangerous Gases

As well as the concerns from confined space entry,marine personnel must be aware of the cargo they are hauling and the ambient dangers that can exist. The IBC code of the IMO splits dangerous cargo into three types.

Type 1 ship is a chemical tanker intended to transport chapter 17 (in the IBC code) products with very severe environmental and safety hazards that require maximum preventive measures to preclude an escape of such cargo.

Type 2 ship is a chemical tanker intended to transport chapter 17 (in the IBC code) products with appreciably severe environmental and safety hazards that require maximum preventive measures to preclude an escape of such cargo.

Type 3 ship is a chemical tanker intended to transport chapter 17 (in the IBC code) products with sufficiently severe environmental and safety hazards that require maximum preventive measures to preclude an escape of such cargo.

Chapter 17 in the IBC code lists whether there is a concern from flammable and/or toxic products for each hauled cargo and what types of precautions need to be taken, such as inerting the cargo. Mariners should become aware of all threshold limit values (ACGIH TLVs) or permissible exposure limits (OSHA PELs) for the cargo that is hauled.

Hydrogen Sulfide

Hydrogen sulfide (H2S) is a colorless gas that at low concentrations famously has an odor similar to rotten eggs. At higher concentrations, H2S rapidly deadens the sense of smell. See Table 1.

Much of the crude oil hauled in oil tankers has reduced levels of H2S; however, from time to time, a ship will receive oil with a higher-than-expected level of H2S— sometimes called “sour” oil. Ballast tanks also can contain H2S because sea life brought in when ballast water is taken on can decompose. And H2S also can be encountered in refined products, such as naptha, fuel oil, bitumens, and gas oils.

Exposure limits for H2S vary widely as a function of jurisdiction. The most widely recognized standards for H2S reference an 8-hour TWA of 10 ppm or 20 ppm and a 15-minute STEL of no more than 15 ppm. Concentrations above 100 ppm should be regarded as immediately dangerous to life and health.

The American Conference of Governmental Industrial Hygienists (ACGIH) publishes guidelines to assist in the control of health hazards in the workplace, including toxic gases such as H2S. ACGIH recommendations are published as Threshold Limit Values (TLVsTM). In many jurisdictions, ACGIH TLVs have the force of law. In some cases, local regulations or corporate guidelines may take an even more stringent approach. The ACGIH TLV currently in effect for H2S consists of two parts: an 8-hour TWA of 10 ppm and a 15- minute STEL of 15 ppm.

Confined space entry is one of the most hazardous industrial tasks performed by workers. When this activity is done onboard marine vessels hauling flammable and toxic vapors, confined space entry takes on a whole new concern. When safety personnel are made knowledgeable of all safety concerns, this task stays dangerous but becomes manageable.

This article originally appeared in the November 2008 issue of Occupational Health & Safety.